Plastic HDPE Geocell for Road Slope Reinforcement

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 g/m²

- Supply Capability:

- 100000 g/m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

HDPE Geocell with CE Certificate (Manufaturer directly!)

Geocell Cellular Confinement Systems / Geocell / Geocell systems / HDPE Smooth/Textured Plastic Geocell

1.welding distance:330-1000mm

2.height:50-250mm

3.Textured or Smooth surface

4.Color: black,brown,green

we are one of the largest geocell factory in China.

Specification:

Polymer Density | High Density Polyethylene with density of 0.935 - 0.965 g/cm3 ASTM D 1505 |

Environmental Stress Crack Resistance | > 4000 hours ASTM D 1693 |

Carbon Black Content | Carbon black content 1.5% - 2.0% ASTM D 1603 |

Sheet Thickness | Smooth:1.1mm,1.2mm,textured:1.5mm ASTM D 5199 |

Cell Details | welding distance:330-1000mm |

Cell Depth | 50-250mm |

Seam Peel Strength | As per US Army Corps of Engineer's Report GL-86-19 Appendix A |

Seam Hang Strength | A 100mm wide seam sample supports a 72.5 kg load for a minimum of 30 days in an ambient room temperature environment. |

Certification | CE ,ISO |

Item Model | Height (mm) | Welding distance (mm) | Sheet thickness (mm)

| Tensile yield strength of the cell (MPa) | Seam peel strength (N/250px) | |

smooth | textured | |||||

TGLG-50-400 | 50 | 400 | 1~1.1 | 1.4~1.5 | 20.0 | 1000 |

TGLG-100-400 | 100 | 400 | 1~1.1 | 1.4~1.5 | 20.0 | 1000 |

TGLG-150-400 | 150 | 400 | 1~1.1 | 1.4~1.5 | 20.0 | 1000 |

TGLG-200-400 | 200 | 400 | 1~1.1 | 1.4~1.5 | 20.0 | 1000 |

TGLG-75-330 | 75 | 330 | 1~1.1 | 1.4~1.5 | 20.0 | 1000 |

TGLG-100-330 | 100 | 300 | 1~1.1 | 1.4~1.5 | 20.0 | 1000 |

TGLG-150-330 | 150 | 330 | 1~1.1 | 1.4~1.5 | 20.0 | 1000 |

Notes:

(1)welding distance:330mm~800mm

(2)we can produce smooth/textured geocell, perforated/non-perforated geocell

(3)The special spec or size can be manufactured according to the demands of the contract

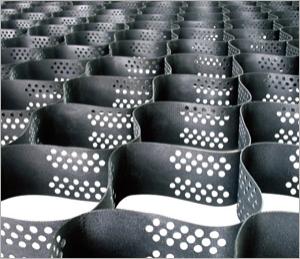

Images of Geocell

- Q:How do geocells reduce the need for geogrid reinforcement?

- Geocells reduce the need for geogrid reinforcement by providing a three-dimensional structure that confines and stabilizes the infill material, increasing its load-bearing capacity. This eliminates or reduces the reliance on additional geogrids, saving costs and time in construction projects.

- Q:Can geocells be used in underground pipe protection?

- Yes, geocells can be used in underground pipe protection. Geocells are three-dimensional honeycomb-like structures made of high-density polyethylene (HDPE) that provide effective support and protection to underground pipes. They help distribute the load and prevent soil erosion around the pipes, ensuring their long-term stability and functionality. Geocells also offer additional benefits like easy installation, cost-effectiveness, and environmental sustainability.

- Q:Can geocells be used for bridge abutment protection?

- Yes, geocells can be used for bridge abutment protection. Geocells are highly effective in providing erosion control and slope stabilization, making them suitable for protecting bridge abutments against soil erosion and scouring. They create a stable and reinforced structure that prevents soil movement and helps maintain the integrity and longevity of the bridge abutments.

- Q:Are geocells resistant to chemicals?

- Yes, geocells are typically resistant to chemicals. They are designed to withstand exposure to a wide range of chemicals found in soil, water, and other environmental conditions. This chemical resistance ensures the longevity and effectiveness of geocells in various applications.

- Q:How do geocells improve the performance of landfill covers?

- Geocells improve the performance of landfill covers by providing a stable and reinforced structure that prevents erosion and soil movement. They enhance the load-bearing capacity of the cover, allowing for heavier machinery and vehicles to operate on top without damaging the liner or underlying waste. Additionally, geocells enhance drainage and prevent the accumulation of water, reducing the risk of leachate formation and enhancing overall stability and longevity of the landfill cover system.

- Q:What is the environmental impact of using geocells?

- The environmental impact of using geocells is generally positive. Geocells, which are three-dimensional cellular confinement systems, can be used for various applications such as erosion control, soil stabilization, and slope protection. Their use reduces the need for traditional construction materials like concrete and asphalt, minimizing the extraction and consumption of natural resources. Geocells also promote vegetative growth, which helps in reducing soil erosion and improving biodiversity. Moreover, the use of geocells can lead to reduced carbon emissions during construction processes compared to conventional methods. Overall, geocells offer sustainable and eco-friendly solutions for various environmental challenges.

- Q:Can geocells be used for pipeline backfill?

- Yes, geocells can be used for pipeline backfill. Geocells are three-dimensional honeycomb-like structures made of high-density polyethylene (HDPE) material that can be filled with various backfill materials such as soil, sand, or gravel. These cells provide confinement and stability to the backfill material, improving load-bearing capacity and preventing lateral displacement. This makes geocells an effective solution for pipeline backfill, ensuring long-term stability and minimizing potential damages to the pipeline.

- Q:Can geocells be used for slope greening?

- Yes, geocells can be used for slope greening. Geocells are three-dimensional cellular confinement systems that provide structural reinforcement and soil stabilization. When used on slopes, geocells help prevent soil erosion and promote vegetation growth, making them an effective solution for slope greening. The cells can be filled with soil and planted with vegetation, creating a stable and green surface on slopes.

- Q:Are geocells suitable for pipeline trench reinforcement?

- Yes, geocells are suitable for pipeline trench reinforcement. Geocells are three-dimensional cellular confinement systems made from high-strength materials. They provide stability, load distribution, and erosion control to the soil surrounding the pipeline. Geocells enhance the load-bearing capacity of the trench, prevent soil erosion, and minimize the risk of pipeline damage. Additionally, geocells are easy to install and cost-effective, making them an ideal choice for pipeline trench reinforcement.

- Q:Can geocells be used for revetment applications?

- Yes, geocells can be used for revetment applications. Geocells are three-dimensional cellular confinement systems that can provide structural stability and erosion control in various civil engineering applications, including revetments. They can be filled with soil, aggregate, or other suitable materials to create a stable and permeable structure that can resist the forces of erosion and protect slopes, embankments, and shorelines from erosion and scour.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Plastic HDPE Geocell for Road Slope Reinforcement

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 g/m²

- Supply Capability:

- 100000 g/m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords