PET long fiber white color non woven geotextile

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 g/m²

- Supply Capability:

- 100000 g/m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Discription

1. polypropylene (PP), or polyester (PET) material , needle punched

2. weight: 100g/m² to 1500g/m²

width : 1.0m-8m

length: 50-100m (or at requested)

monolayer or multilayer (reinforcement geotextiles)

long fiber or short fiber

3.Color: all kinds of color are available.

4.The fabric can also be heat treated by infrared at customer's requirements.

Applications

1. Filtration

The filtration layer of the dykes, river canal, seacoast, concrete slope, retaining walls. At the same time of preventing the clay granule from passing, it allows the water and the gas pass through freely.

2 .Separation

The isolation of the railway dregs and the roadbed, roadbed and the soft base, surface of the airdrome and parking lot and the groundsill, different dam materials. It isolates the soil and the gravel of two kinds different granule pathway from the groundsill or other buildings.

3. Reinforcement

The highway, railway, soil-stone dam, breakwater, airport, backfill soil of retaining wall, slope protection, etc in which distributes the earth stress, prevents the side-displacement of the earth body and improves the earth body stability.

4 .Protection

It prevents the bank from being washed out, protects the bank and the bottom, prevents the water and soil from being washed away.

Technical data of the nonwoven geotextile:

| WEIGHT (g) | 100 | 150 | 200 | 250 | 300 | 350 | 400 | 450 | 500 | 600 | 800 | NOTE |

BASIS WEIGHT TOLERANCE (%) | -8 | -8 | -8 | -8 | -7 | -7 | -7 | -7 | -6 | -6 | -6 | |

THICKNESS ≥MM | 0.9 | 1.3 | 1.7 | 2.1 | 2.4 | 2.7 | 3.0 | 3.3 | 3.6 | 4.1 | 5.0 | |

TENSILE STRENGTH AT BREAKING ≥KN/m | 2.5 | 4.5 | 6.5 | 8.0 | 9.5 | 11.0 | 12.5 | 14.0 | 16.0 | 19.0 | 25.0 | MD&CD |

CBR PLUNGER STRENGTH ≥KN | 0.3 | 0.6 | 0.9 | 1.2 | 1.5 | 1.8 | 2.1 | 2.4 | 2.7 | 3.2 | 4.0 | |

TEARING STRENGTH ≥KN | 0.08 | 0.12 | 0.16 | 0.20 | 0.24 | 0.28 | 0.33 | 0.38 | 0.42 | 0.46 | 0.60 | |

BREADTH TOLERANCE (%) | -0.5 | |||||||||||

ELONGATION AT BREAKING (%) | 25-100 | MD&CD | ||||||||||

EOS O90mm | 0.07-0.2 | |||||||||||

VERTICAL PERMEABILITY (CM/S) | K×(10-1~~10-3) | K=1.0-9.9

| ||||||||||

Item (g/m2) | 100 | 150 | 200 | 250 | 300 | 350 | 400 | 450 | 500 | 600 | 800 | Note |

Mass error in unit area (%) | -8 | -8 | -8 | -8 | -7 | -7 | -7 | -7 | -6 | -6 | -6 | |

Thickness (mm) ≥ | 0.9 | 1.3 | 1.7 | 2.1 | 2.4 | 2.7 | 3.0 | 3.3 | 3.6 | 4.1 | 5.0 | |

Error of width (%) | -0.5 | |||||||||||

Breaking strength (KN/m)≥ | 2.5 | 4.5 | 6.5 | 8.0 | 9.5 | 11.0 | 12.5 | 14.0 | 16.0 | 19.0 | 25.0 | MD/CD |

Elongation at break | 25~100% | |||||||||||

CBR puncture resistance (KN)≥ | 0.3 | 0.6 | 0.9 | 1.2 | 1.5 | 1.8 | 2.1 | 2.4 | 2.7 | 3.2 | 4.0 | |

Equivalent Pore size O90( O95) | 0.07~0.2 mm | |||||||||||

Vertical permeability coefficient | K×(10-4~10-3)cm/s | K=1.0-9.9 | ||||||||||

Tearing strength (KN)≥ | 0.08 | 0.12 | 0.16 | 0.20 | 0.24 | 0.28 | 0.33 | 0.38 | 0.42 | 0.46 | 0.60 | MD/CD |

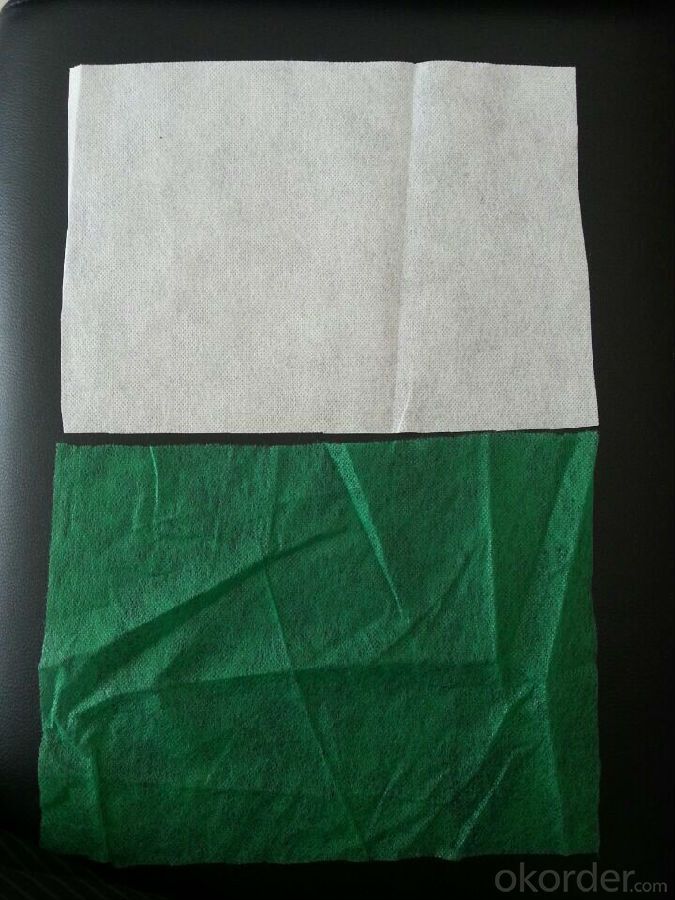

Images of non woven geotextile

- Q:Can geotextiles be used in rockfall protection works?

- Yes, geotextiles can be used in rockfall protection works. Geotextiles can provide reinforcement and stabilization to slopes and embankments, helping to prevent soil erosion and rockfall. They can be used as a barrier between the rockfall source and the protected area, absorbing or redirecting the energy of falling rocks. Additionally, geotextiles can enhance the effectiveness of other rockfall protection measures, such as rockfall nets or fences, by providing additional support and filtration.

- Q:Garage roof covered with non-woven or geotextile cloth

- Garage roof, are used geotextile, Huazhi geotextile material manufacturers

- Q:What is the meaning of the process equipment and equipment for producing geotextiles?

- What is the meaning of the process equipment and equipment for producing geotextiles?

- Q:What are the different methods of geotextile installation?

- Some of the different methods of geotextile installation include trenching and backfilling, direct placement, and anchoring. Trenching and backfilling involves excavating a trench, laying the geotextile in the trench, and then backfilling it with soil. Direct placement involves simply placing the geotextile on the intended surface without any additional steps. Anchoring involves fixing the geotextile to the ground using various anchoring techniques such as stakes, pins, or sandbags. These methods can be chosen based on the specific project requirements and site conditions.

- Q:What are the key considerations for geotextile installation in high temperature environments?

- The key considerations for geotextile installation in high temperature environments include selecting geotextiles that are resistant to thermal degradation, ensuring proper anchoring and securing of the geotextiles to prevent movement or displacement, and considering potential expansion and contraction of the geotextiles due to temperature fluctuations. Additionally, it is important to assess the long-term performance and durability of the geotextiles under high temperature conditions and to monitor their performance regularly to detect any signs of degradation or failure.

- Q:How do geotextiles help with reinforcement of geogrid retaining walls?

- Geotextiles help with the reinforcement of geogrid retaining walls by providing additional strength and stability. They act as a barrier between the soil and the geogrid, preventing soil particles from migrating through the geogrid openings. This helps to maintain the integrity of the geogrid structure and enhances its ability to retain the surrounding soil. Additionally, geotextiles can distribute the applied loads more evenly across the geogrid, reducing stress concentrations and increasing the overall stability of the retaining wall.

- Q:What are the factors to consider when designing geotextile-reinforced walls?

- When designing geotextile-reinforced walls, there are several factors that need to be considered. Firstly, the strength and stability of the geotextile material itself is crucial. The geotextile should have sufficient tensile strength and durability to withstand the loads and pressures exerted on the wall. Secondly, the soil characteristics and properties must be thoroughly analyzed. Factors such as soil type, compaction, and shear strength are essential in determining the design of the reinforced wall. The slope of the site and the anticipated slope stability also play a significant role. The angle of inclination and the height of the wall will impact the design and reinforcement requirements. Additionally, proper drainage is vital to prevent water buildup and potential failure of the wall. The design should incorporate adequate measures to ensure effective water management and prevent hydrostatic pressure. Considering the environmental conditions is essential. Factors such as temperature variations, freeze-thaw cycles, and corrosive substances in the soil must be taken into account to ensure the longevity of the geotextile-reinforced wall. Lastly, construction techniques and maintenance requirements should be considered during the design phase. The ease of installation, access for maintenance, and potential future repairs should all be evaluated to ensure the practicality and sustainability of the reinforced wall.

- Q:Geotextile in the asphalt layer under what role

- Waterproof, isolated

- Q:What are the specifications for geotextiles in coastal protection projects?

- The specifications for geotextiles in coastal protection projects typically include factors such as material strength, permeability, durability, and resistance to UV degradation. The geotextiles used in these projects should have high tensile strength to withstand the forces exerted by waves and tides, as well as good permeability to allow for proper water drainage. They should also be resistant to chemicals and biological degradation, as well as have the ability to withstand harsh weather conditions. Additionally, they may need to meet specific standards or certifications set by regulatory bodies or project requirements.

- Q:What are the factors to consider when selecting a geotextile?

- When selecting a geotextile, there are several factors that need to be considered. Firstly, the intended application of the geotextile must be evaluated. Different geotextiles have specific properties that make them suitable for certain applications, such as erosion control, soil stabilization, drainage, or filtration. Secondly, the physical and mechanical properties of the geotextile need to be examined. This includes characteristics such as tensile strength, permeability, puncture resistance, and durability, which should align with the requirements of the specific project. Additionally, the environmental conditions, such as temperature, pH levels, and exposure to chemicals, should be taken into account to ensure the geotextile can withstand these conditions without deterioration. Lastly, the cost and availability of the geotextile should be considered, as it should align with the project budget and be readily accessible for procurement. By considering these factors, one can make an informed decision when selecting a geotextile that best suits their project needs.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

PET long fiber white color non woven geotextile

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 g/m²

- Supply Capability:

- 100000 g/m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords