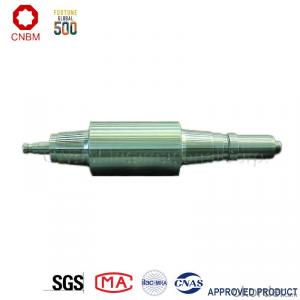

Mill Rolls High Speed Steel Roller With Good Quality

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2 m.t.

- Supply Capability:

- 41000 m.t./month

- Option:

- 650X1780X5540; 650X1780X5540; 680X2080X5920

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Item specifice

Company Profile

CNBM International Corporation (CNBM International) is the most important trading platform of CNBM Group Corporation, a state-owned company under the direct supervision of State-owned Assets Supervision and Administration Commission of the State Council.

CNBM Group is integrated with four business segments: Manufacture, R&D,Sets of equipment and Logistics trading.Mill rolls are our main products.

CNBM International is highly recognized by its business partners and clients all over the world and has established good business relationship with the customers in over 120 countries and regions all over the world.

The product introduction of mill roll

Equipped with advanced technological facilities on melting, casting, forging, heat treating and mechanical machining, our factory has formed 9 professional complete roll manufacturing lines of cast steel, cast iron and forged steel rolls such as strip mill rolls, heavy section mill rolls, wire & bar rolls, special shaped rolls and small-sized cold rolls and specialized production lines of bloom and slab CCM, coke oven equipments and wind power products. Annual production capacity of mill rolls is 500,000 tons, metallurgical equipment is 80,000 tons.

Workshop

Workshop is the core of our company and undertakes all of scientific research work. The company specially produces and supplies all kinds of roll used for hot strip mill, cold strip mill, plate & heavy plate mill, large-sized section mill, universal mill etc.

Products & Specification

| Mill | Application | Material | Product Specification | ||

| Hot Strip Mill | Large-sized vertical roll | Special alloy cast roll, Adamite | All Sizes | ||

| Small-sized vertical roll | Adamite, HiCr iron | ||||

| Roughing work roll | Special alloy cast steel, Adamite, HiCr steel, Semi-HSS, HiCr iron | ||||

| Finish rolling | Early stand work roll | HiCr iron, HSS | |||

| Later stand work roll | ICDP, HSS | ||||

| Finishing back-up roll | Duplex cast steel | D≤¢2000,W≤80t | |||

| Alloy forged steel | D≤¢2000,W≤75t | ||||

| Temper rolling | Work roll | HiCr iron | All Sizes | ||

| Alloy forged steel | |||||

| Back-up roll | ICDP | ||||

| Duplex cast steel | D≤¢2000, W≤80t | ||||

| Alloy forged steel | D≤¢2000, W≤75t | ||||

| Mill | Application | Material | Product specification |

Cold strip mill & Single stand cold mill | Work roll | Alloy forged steel | All Sizes |

| Intermediate roll | Alloy forged steel | ||

| Temper roll | Alloy forged steel | ||

| Back-up roll | Duplex cast steel | D≤¢2000,W≤80t | |

| Alloy forged steel | D≤¢2000,W≤75t | ||

Largesized universal structural mill | Break-down roll | Special alloy cast steel, alloy nodular iron | All Sizes |

| Horizontal collar | High carbon adamite (duplex) | ||

| Vertical collar | High carbon adamite, HiCr iron | ||

| Edger roll Edger roll | High carbon adamite | ||

| Shaft | Alloy forged steel |

| Mill | Application | Marterial | Product Specification | |

| CSP | Vertical Roll | Adamite, Special alloy cast steel, HiCr iron | All Sizes | |

| Roughing work roll | Semi-HSS, HiCr Steel | |||

| Finish rolling | Early stand | HiCr iron, HSS | ||

| Later stand | ICDP, HSS | |||

| Roughing & Finishing back-up roll | Duplex cast steel | D≤¢2000,W≤80t | ||

| Alloy forged steel | D≤¢2000,W≤75t | |||

| Steckel Mill | Vertical roll | Adamite, Special alloy cast steel | All Sizes | |

| Roughing work roll | ICDP, HiCr iron | |||

| Finishing work roll | HiCr iron, ICDP | |||

| Back-up roll | Duplex cast steel | D≤¢2000,W≤80t | ||

| Alloy forged steel | D≤¢2000,W≤75t | |||

| Plate & Heavy plate mill | Rough rolling | 2-hi work roll | Special alloy cast steel, Tool steel | All Sizes |

| 4-hi work roll | HiCr iron, ICDP | |||

| Finishing work roll | HiCr iron, ICDP | |||

| Single stand work roll | HiCr iron, ICDP | |||

| Back-up roll | Duplex cast steel | D≤¢2000,W≤80t | ||

| Alloy forged steel | D≤¢2000,W≤75t | |||

Quality Control

The company has the most advanced experimental and testing equipments in global mill roll industry, including direct-reading spectrometer, spectrum analyzer , X-ray fluorescence analyzer, scanning electronic microscope, energy disperse spectroscopy, X-ray diffractometer, image analyzer, high/low temperature metallographic microscope, X-ray stress meter, brittleness temperature tester, thermal analogue machine, dilatometer, macro and micro hardness tester, OMNISCAM-1X automatic flaw detection, USN60 ultrasonic flaw detector, magnetic powder and non-destructive flaw detection etc,. The advanced inspection equipments and experimental methods provide guarantee for quality control and experiment on material, usability test and performance.

Professionals & Comprehensive Inspection

The factories of CNBM invested 2.3 billion RMB for large-scale

CNBM international Corporation has completed equipment and technology upgrade transformation, which was concentrated on three projects, production line of centrifugal casting rolls for hot strip and plate mill, forged roll for cold/hot strip mill, national class technology center and roll material lab. Through upgrade transformation, the following targets have been achideved:

(1)It becomes the world's biggest specialized mill roll maker with the largest production scale, the most complete specifications of products and the most extensive coverage of various rolls used on rolling mill.

(2) The technology of equipments has reached international leading level.

(3) "Mechanization, automation, intellectualization, digitization" of equipments obviously improve the quality control ability.

(4) New types of research instruments improve the R&D capacity of products.

Customers Visit

FAQ

Q:Are you a trading company or manufacturer?

A:CNBM is a large-scale central governmental industrial group with its own manufacturing sector, research and development sector, trading sector and logistics sector.

Q:I have some special requirement about specifications.

A:We have a well-rounded product range, which endows us with the capability of applying many special specifications. Please feel free to contact us with yours.

Q:Do you accept OEM service?

A:Yes, we do.

Q:What is your delivery time?

A:It depends on the size/complexity of your order and our own production schedule. Usually we provide a faster delivery than the industry's average.

Q:What is the payment term?

A:Our payment terms are negotiable.

Q:Can I have my own logo on the product?

A:Sure, we can apply your own logo on the products according to your requirement.

- Q:What are the different casting methods used with metal casting machinery?

- Metal casting machinery employs various casting methods, each possessing its own merits and applications. Sand casting, a versatile and cost-effective technique, involves compacting sand around a pattern to create a mold. This method is well-suited for both small and large-scale production and enables the formation of intricate shapes, rendering it a popular choice across industries. Investment casting, known as lost wax casting, entails coating a wax pattern with a ceramic shell. The wax is then melted away and replaced with molten metal. This method is ideal for producing detailed and intricate parts, although it tends to be more time-consuming and costly compared to other methods. Die casting, a highly efficient approach, injects molten metal into a steel mold under high pressure. This process yields parts with exceptional dimensional accuracy and surface finish, making it a preferred option for mass production of small to medium-sized components. Centrifugal casting utilizes centrifugal force to distribute molten metal into a mold. This method is particularly suitable for manufacturing cylindrical and tubular parts, such as pipes and cylinders. It allows for precise control over wall thickness and produces parts with excellent mechanical properties. Continuous casting generates long, uninterrupted metal strands or billets. Molten metal is poured into a water-cooled mold, solidifying as it traverses through. This technique finds extensive use in the production of materials like steel and aluminum. Lastly, permanent mold casting capitalizes on reusable molds made from materials like metal or graphite. Molten metal is poured into the mold, which is then cooled and opened to extract the solidified part. Permanent mold casting is well-suited for high-volume production, ensuring consistent quality. To summarize, metal casting machinery employs various methods, including sand casting, investment casting, die casting, centrifugal casting, continuous casting, and permanent mold casting. Each technique possesses distinct advantages and is selected based on factors such as desired part characteristics, production volume, cost considerations, and industry-specific requirements.

- Q:Can metal casting machinery be used for producing large castings?

- Large castings can be produced using metal casting machinery. Foundry equipment, which falls under metal casting machinery, is specifically designed to handle a wide range of casting sizes, including small to extremely large ones. The production capacity of these machines determines the size of the castings they can create. Thanks to advancements in technology and equipment, the casting industry is now able to manufacture large and intricate castings that were previously considered difficult or even impossible. These machinery systems are equipped with features such as high melting capacities, large molds, and efficient pouring mechanisms, allowing the production of large castings for various applications, including industrial machinery, automotive components, and architectural structures. Moreover, different casting methods, such as sand casting, investment casting, and die casting, can be employed to manufacture large castings, offering flexibility in the manufacturing process. In conclusion, metal casting machinery is highly efficient and effective in producing large castings.

- Q:What are the common mold design considerations for metal casting machinery?

- There are several common mold design considerations that need to be taken into account when designing molds for metal casting machinery. These considerations play a crucial role in ensuring the success of the casting process and the quality of the final product. Firstly, one of the most important considerations is the material selection for the mold. The material used should have good thermal conductivity and high resistance to wear and corrosion, as it will be subjected to high temperatures and contact with molten metal. Commonly used mold materials include steel, iron, and refractory materials. Another consideration is the design of the gating system. The gating system refers to the channels through which the molten metal is poured into the mold. It is important to design the gating system in a way that allows for the proper flow and distribution of the molten metal throughout the mold cavity. This helps to prevent defects such as porosity and incomplete fillings. The mold design should also consider the cooling system. Efficient cooling is essential to control the solidification rate of the molten metal and prevent the formation of internal defects. The cooling system may include water jackets, cooling channels, or the use of insulating materials to regulate the cooling rate. Additionally, the mold design should take into account the parting line, which is the line where the mold splits into two halves. The parting line should be strategically placed to facilitate the removal of the casting from the mold without causing any damage. Proper draft angles should also be incorporated to allow for easy mold release and prevent the formation of undercuts. Furthermore, considerations should be made for the venting system. The venting system allows for the escape of gases and air during the casting process. Inadequate venting can lead to defects such as gas porosity and trapped air pockets, affecting the quality of the final product. Lastly, the mold design should consider factors such as the dimensional accuracy of the final casting, the surface finish requirements, and the ease of mold assembly and disassembly for maintenance and repair purposes. In conclusion, the common mold design considerations for metal casting machinery involve material selection, gating system design, cooling system design, parting line placement, draft angles, venting system design, and various other factors. By carefully considering these design considerations, manufacturers can produce high-quality castings with minimal defects and ensure the efficiency and effectiveness of the metal casting process.

- Q:Can metal casting machinery be used for the production of mining equipment parts?

- Yes, metal casting machinery can be used for the production of mining equipment parts. Metal casting involves pouring molten metal into a mold and allowing it to solidify, resulting in the creation of a desired shape. This process is versatile and can be used to manufacture a wide range of components, including those used in mining equipment. Mining equipment parts often require high strength and wear resistance to withstand the harsh conditions of the mining industry. Metal casting allows for the use of various metals and alloys that possess these properties, such as steel, iron, and various metal alloys. These materials can be cast into complex shapes and sizes, making them suitable for manufacturing mining equipment parts. Metal casting machinery, such as foundries and casting machines, provide the necessary equipment and tools to carry out the casting process. These machines can melt the metal, control the temperature, and pour it into molds. Additionally, they can also be equipped with advanced technologies, such as computer-aided design (CAD) and computer numerical control (CNC), to ensure precise and accurate casting of mining equipment parts. Furthermore, metal casting allows for cost-effective production of mining equipment parts. It enables the production of large quantities of parts in a relatively short amount of time. The molds used in casting can be reused, reducing the overall production costs. This cost-effectiveness is particularly beneficial for the mining industry, where equipment parts often need to be replaced or repaired due to the demanding nature of the work. In conclusion, metal casting machinery can be effectively used for the production of mining equipment parts. It provides the necessary capabilities to cast various metals and alloys into complex shapes and sizes, meeting the high strength and wear resistance requirements of the mining industry. Additionally, metal casting offers cost-effective production, making it a suitable choice for manufacturing mining equipment parts.

- Q:Can metal casting machinery handle the production of large cylindrical castings?

- Yes, metal casting machinery is capable of handling the production of large cylindrical castings.

- Q:What are the different types of research and development initiatives in the field of metal casting machinery?

- Metal casting machinery research and development initiatives encompass various areas, all with the goal of enhancing efficiency, productivity, and quality. One particular initiative concentrates on the development of novel materials and alloys for metal casting. Scientists study the properties and performance of different materials and alloys to determine their suitability for specific casting applications. By creating new materials, researchers can strengthen the durability, heat resistance, and overall performance of metal casting machinery. Another initiative seeks to improve the design and manufacturing processes of metal casting machinery. This includes the advancement of new casting techniques like rapid prototyping and additive manufacturing, which streamline production and reduce costs. Additionally, researchers are enhancing the precision and accuracy of casting machinery through advanced computer simulations and modeling techniques. The metal casting industry has recently placed emphasis on sustainability, leading to research and development initiatives focusing on environmentally friendly casting processes. This involves exploring alternative energy sources such as solar and wind power to minimize the environmental impact of metal casting machinery. Researchers are also investigating ways to minimize waste generation and optimize material usage in the casting process. Furthermore, research and development initiatives aim to integrate automation and robotics into metal casting machinery. Automation improves efficiency and productivity by reducing human error and increasing production speeds. Robotics can handle tasks like mold handling and pouring, enhancing precision and repeatability in casting operations. Overall, these diverse research and development initiatives aim to drive innovation, improve materials, design and manufacturing processes, promote sustainability, and incorporate automation. By doing so, they enhance the overall performance and competitiveness of metal casting machinery in various industries.

- Q:What are the process control measures for metal casting machinery?

- Process control measures for metal casting machinery are necessary to ensure the production of high-quality castings and to maintain operational efficiency. These measures involve monitoring and regulating various aspects of the metal casting process to minimize defects, optimize productivity, and ensure worker safety. Some key process control measures for metal casting machinery include: 1. Temperature control: Maintaining the proper temperature is crucial in metal casting to achieve the desired metal properties and prevent defects. This can be achieved through the use of temperature sensors and control systems that regulate the heating and cooling processes. 2. Metal composition control: Metal composition is a critical factor that influences the properties of the final casting. Process control measures involve monitoring the alloy composition and making necessary adjustments to ensure consistency and meet specific requirements. This can be achieved through the use of spectrometers and chemical analysis techniques. 3. Molding and core quality control: The quality of the mold and cores used in metal casting significantly affects the final product. Process control measures involve monitoring and controlling various parameters such as sand quality, moisture content, compaction, and curing time to ensure consistent and defect-free molds and cores. 4. Pouring and filling control: Proper control of the pouring and filling process is essential to prevent defects like porosity, shrinkage, and inclusions. This can be achieved through the use of automated pouring systems, flow control devices, and real-time monitoring tools to ensure consistent and controlled metal flow. 5. Solidification control: The cooling and solidification process of the molten metal plays a crucial role in determining the final casting's quality and properties. Process control measures involve monitoring and controlling cooling rates, controlling the use of chillers or insulating materials, and optimizing the gating and riser systems to ensure uniform solidification and minimize defects. 6. Quality inspection and testing: Regular quality inspections and testing throughout the metal casting process are vital process control measures. This can involve non-destructive testing techniques such as X-ray, ultrasonic, or visual inspection to detect any defects or inconsistencies. It also includes dimensional inspection and mechanical testing to ensure the final product meets the desired specifications. 7. Safety measures: Process control measures also encompass ensuring the safety of workers operating metal casting machinery. This includes implementing safety protocols, providing personal protective equipment, and regularly inspecting and maintaining the machinery to minimize the risk of accidents or injuries. By implementing these process control measures, metal casting machinery can produce high-quality castings consistently, optimize productivity, minimize waste, and ensure the safety of workers.

- Q:What are the different types of patterns used in metal casting machinery?

- There are several different types of patterns used in metal casting machinery, including solid patterns, split patterns, match plate patterns, and cope and drag patterns. Solid patterns are made from a single piece of wood or metal and create a solid mold cavity. Split patterns are made in two or more pieces to allow for easy removal from the mold. Match plate patterns consist of a top and bottom plate that are used to create multiple molds simultaneously. Cope and drag patterns are used in sand casting and consist of two separate halves that are packed with sand to create the mold cavity.

- Q:What are the waste reduction methods for metal casting machinery?

- Some waste reduction methods for metal casting machinery include using recycled materials, implementing efficient melting and cooling processes, optimizing mold design to minimize material waste, and properly disposing and recycling any leftover materials or byproducts.

- Q:What are the different types of sand used in metal casting machinery?

- There are several different types of sand used in metal casting machinery, each with its own specific characteristics and applications. The most commonly used sand in metal casting is called silica sand, also known as industrial sand. It is made up of small, angular grains of quartz, and its high silica content makes it heat-resistant and able to withstand high temperatures during the casting process. Another type of sand used in metal casting is chromite sand. This sand is made from a mineral called chromite, which contains a high percentage of chromium. Chromite sand has excellent thermal conductivity and is often used in foundries that produce steel and iron castings. Zircon sand is another popular choice in metal casting. It is made from the mineral zirconium silicate and has a high melting point, making it suitable for casting metals that require very high temperatures, such as titanium and steel alloys. Olivine sand is another type of sand used in metal casting machinery. It is made from a mineral called olivine, which is a magnesium iron silicate. Olivine sand is known for its high refractoriness, meaning it can withstand high temperatures without melting or deforming. It is often used in foundries that produce non-ferrous castings. Lastly, there is specialty sand, which is a blend of different types of sand specifically formulated for certain casting applications. This can include sands with additives like bentonite or coal dust to improve mold strength or sands with specific grain sizes for better surface finish. In conclusion, the different types of sand used in metal casting machinery include silica sand, chromite sand, zircon sand, olivine sand, and specialty sand. Each type has its own unique properties and is chosen based on the specific requirements of the casting process and the metal being cast.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Mill Rolls High Speed Steel Roller With Good Quality

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2 m.t.

- Supply Capability:

- 41000 m.t./month

- Option:

- 650X1780X5540; 650X1780X5540; 680X2080X5920

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords