Microporous Mineral Fiber Board: CE,ISO,SGS Certification Heat Insulation

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2000 pc

- Supply Capability:

- 30000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Description of Microporous Insulation Board:

CMDS Microporous Insulation Board is specially designed for steel industry & metallurgy with very good thermal and mechanical properties. The formulation is an opacified blend of filament reinforced pyrogenic silica. The coverings is water repellent to assure the stability of the microporous board when moisture may occur due to castables, mortar etc.

2.Main features of Microporous Insulation Board:

◆ Extremely low thermal conductivity ◆High compressive strength

◆ High thermal stability ◆Environment protection

◆ Easy to handle ◆No harmful inhalable fibers

◆ Resist most chemical attacks ◆Free of organic binders

◆ Non combustible

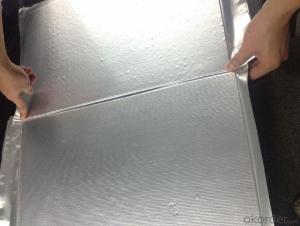

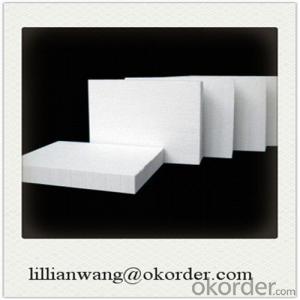

3. Microporous Insulation Board Images:

4. Microporous Insulation Board Technical Parameters

CMDS Microporous Insulation Board can be shaped easily with a simple cutter and taped off with aluminum tape. The board can be fixed in place with the same adhensives that are used for refractory lining.

Application: Ladle, Torpedo Ladle, EAF, Degassers, Cement Rotary Kiln, Ceramic Firing Klin, Aluminum Melting and Holding Furnace and so on. If you need other application picture, please contact with us

5.FAQ

We have organized several common questions for our clients,may help you sincerely:

① How about our board?

A world class manufacturer & supplier of Microporous Insulation Board is one of the large scale professional investment casting production bases in China,consisting of both casting foundry forging and machining factory. Annually more than 8000 tons Precision casting and forging parts are exported to markets in Europe,America and Japan. OEM casting and forging service available according to customer’s requirement.

②How to guarantee the quality of the products?

We have established the international advanced quality management system every link from raw material to final product we have strict quality test; We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

- Q:How to make building glue?

- A building adhesive consisting of 28-50wt% sodium silicate aqueous solution, 34-53wt% quartz sand, and 8-35wt% magnesium silicate. The product of the invention can be used for the bonding of ceramic tile, floor tile, marble, wood and glass in indoor and outdoor decoration of buildings. It can be used as a substitute for cement in the field of tiling. The product of the invention is environment-friendly products without pollution when being produced and used. The utility model has the advantages of low price, strong adhesive force and curing at normal temperature.

- Q:Why is calcium silicate board unsuitable for use in home improvement?

- Calcium silicate board called gypsum composite board, is a kind of porous material, good sound and heat insulation, in indoor air moist circumstance can attract water molecules in air, air drying, and the release of water molecules, can adjust the indoor humidity, dry, increase comfort. It is super fire gypsum material, the flame can produce endothermic reaction, at the same time, the release of water molecules to prevent the fire from spreading, and does not produce any toxic decomposition, corrosive and choking gas, will not produce any smoke or combustibles.

- Q:What's the difference between white cement and ordinary cement?

- The main chemical composition of Portland cement clinker is calcium oxide, silica, alumina and iron oxide. Calcium oxide mainly derived from calcareous raw materials, such as limestone, chalk, marl; alumina and silica from aluminum silicate containing substances, such as clay, blast furnace slag and fly ash; iron oxide is used in sulfuric acid production of sulfur iron slag. For the content of calcium oxide production of Portland cement lime materials in 52%; silicon oxide content of clay in raw materials up to about 57%, the alumina content is less than 20%. In order to reduce the calcination temperature and to produce part of the melt during calcination, a small amount of iron oxide is often added. Of raw materials but also control the content of alkali and Magnesium Oxide, Magnesium Oxide is content in the cement clinker should be less than 5%, total alkalinity (Na2O+K2O) for general cement should be less than 1.2% of low alkali cement should be less than 0.6%.

- Q:Which is better, asbestos free calcium silicate and aluminium silicate refractory fiber?

- Aluminum silicate fiber can be divided into many kinds according to the aluminum content, the use temperature range is relatively large, the heat insulation property is good, but the price is more expensive.

- Q:What kind of insulation material can withstand 350-600 degrees of high temperature?

- GB 50264-97 code for design of thermal insulation engineering for industrial equipment and pipelines98T901 cold storage Atlas of piping and equipment

- Q:What are the raw materials of cement products? What's the function?

- Sand。 Gravel occupies a very large volume in concrete production, reaching 70%~80%. The aggregate surface, structure, adsorption and water content of aggregate should be required. The appropriate amount of sand and gravel can save cement, reduce the cost of concrete production, and improve the strength of concrete.

- Q:What are the new energy-saving building materials? What's new?

- Heat insulation materials and insulation materials collectively referred to as thermal insulation materials.The commonly used thermal insulation material: mineral wool, rock wool, glass wool (in rock, slag as the main raw material, by high temperature melting, made by centrifugal methods such as cotton and thermosetting resin binder insulation products. ) foam plastics and porous polymers, expanded perlite and their products, calcium silicate insulation products, all kinds of composite insulation materials.Application of thermal insulation materials:(1) it is mainly used for thermal insulation of buildings, walls and roofs;(2) thermal insulation of thermal equipment and thermal pipe;(3) a large number of refrigerators and freezers are also used.

- Q:Calcium silicate board for house ceiling, 6mm or 8mm?

- Calcium silicate board with fire prevention, moistureproof, sound insulation, thermal insulation, indoor air in wet conditions can attract water molecules in air, air drying, and the release of water molecules, can adjust the indoor humidity, dry, increase comfort. Natural gypsum products and special fireproof material, the flame can produce endothermic reaction, at the same time, the release of water molecules to prevent the fire from spreading, and does not produce any toxic decomposition, corrosive and choking gas, will not produce any smoke or combustibles.

- Q:Cement is not silicate products

- So, we usually call cement as cementitious material - cement products

- Q:Asbestos free calcium silicate board there is a crack in the kettle, what is the reason?

- Calcium silicate slab blank (blank off off phenomenon is not forming tube adhesion fingerboard blank above)There are two reasons: one is the blank off the vacuum negative pressure is too large, the blank water is too low, low viscosity; two is felt blocked, the billet made worse.The solution is to reduce the negative pressure, strengthen the cloth washing.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Microporous Mineral Fiber Board: CE,ISO,SGS Certification Heat Insulation

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2000 pc

- Supply Capability:

- 30000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords