Micropore Insulation Board ,Heat Insulation materials

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 100 m²

- Supply Capability:

- 10000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Quick Details for Micropore Insulation Board ,Heat Insulation materials

| Type: | Other Heat Insulation Materials | Place of Origin: | (Mainland) | Brand Name: | |

| Model Number: | 1000 | coating: | alumina foil/glass fiber cloth | Dimension: | 1000*500*10/20/30/40/50 mm |

| Density: | 300kg/m3 |

Packaging & Delivery

| Packaging Details: | wooden box |

| Delivery Detail: | 15 days after receipt of pre-payment |

Specifications

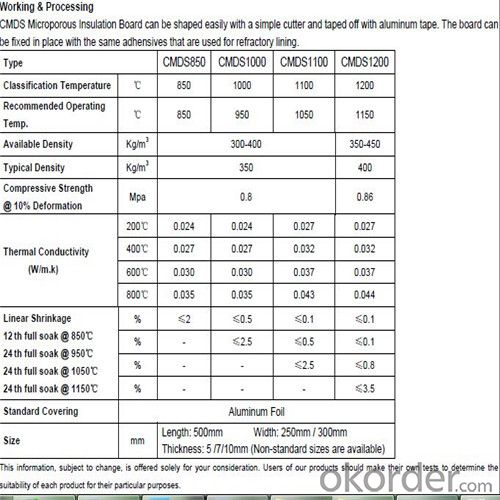

With heat-resistant inorganic fiber as reinforcing material combined with binders, NATI nanometer micro-heat conduction material

Introduction for Micropore Insulation Board ,Heat Insulation materials

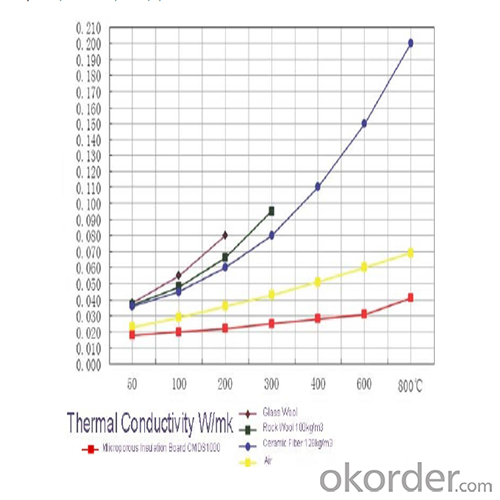

With heat-resistant inorganic fiber as reinforcing material combined with binders, NATI nanometer micro-heat conduction material is made of nanometer porous high-temperature resistant material and functional material with heat shield function through the combination of nanotechnology and special techniques. It has extremely low thermal conductivity that is just as one forth to one tenth that of ceramic fibre thermal insulation material.

Characteristics:

*High temperature resistance.

*Low thermal conductivity.

*Eco-friendliness and safety.

*Low thermal storage.

*Long service life.

Typical Application:

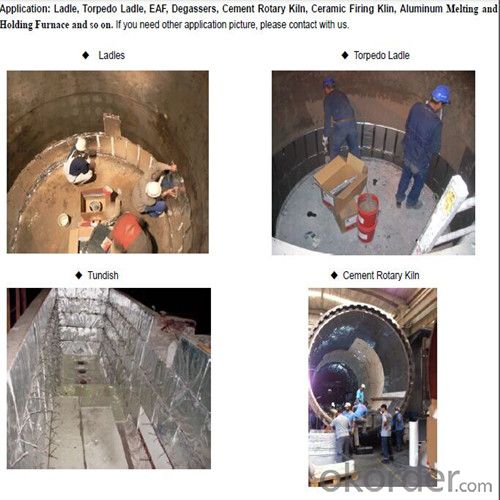

*It is widely used in various industries such as steel, petrochemical

Chemical & Physical Data:

Type | 1000 NATI Micropore Board |

Bulk Density (kg/m3) | 300-350 |

Pressure Strength (MPa) | 0.7 |

Permament Linear Shrinkage %(800℃×6 hour) | 3.5% |

Thermal Conductivity (W/m.K) | 0.020(at 100 ℃) |

0.025(at 200 ℃) | |

0.028(at 400 ℃) | |

0.032(at 600 ℃) | |

0.037(at 800 ℃) |

Standard Dimension:

1000(900)×600(500)×5-20mm

We can also manufacture the special dimensions as customers need.

Q1:Are you a manufacture or trader?

A:Factory+trade(mainly factories,at the same time,we operates other related products).

Q2:Can we visit your factory?

A:Sure,welcome at any time,seeing is believing.

Q3:What's the MOQ of trial order?

A:No limit,We can offer the best suggestions and solutions according to your condition.

Q4:Which payment terms can you accept?

A:T/T,L/C,Western Union,Moneygram,Paypal are available for us.

Q5:After an order is confirmed,when to deliver?

A:15-25days after deposit.

Q6:Is your company accept customization?

A:We have own factory and excellent technical team,and we accept OEM service.

Q7:How about your company's certification?

A:ISO9001 and Test Report,also we could apply other necessary certification.

Q8:How to slove the quality problems?

A:If the products are not confirmed to customer samples or have quality problems,our compay will be responsible to make compensation for it.

Q9:Can you offers samples?

A:Of coures,samples are free but freight paid by the buyers.

Q10:What is the service life of your bricks?

A:The service life of different bricks is unlike.It also depends on your using condition and method.

Thanks for your coming in,if there is any question,I will be glad to help you.

- Q:Can glass fiber textile be used in automotive applications?

- Yes, glass fiber textile can be used in automotive applications. Glass fiber textiles, also known as fiberglass fabrics, are lightweight and have high tensile strength, making them suitable for various automotive components. They are commonly used in the production of car bodies, interior panels, upholstery, and insulation materials. Glass fiber textiles offer excellent resistance to heat, chemicals, and corrosion, making them ideal for withstanding the harsh environments found in automotive applications. Additionally, they provide good acoustic insulation and are fire-resistant, further enhancing their suitability for use in automobiles. Overall, glass fiber textiles are a versatile material that can offer several benefits in automotive applications, including strength, durability, and insulation properties.

- Q:Are glass fiber textiles suitable for aerospace applications?

- Yes, glass fiber textiles are suitable for aerospace applications. Glass fiber textiles, also known as fiberglass textiles, are widely used in the aerospace industry for various applications. They offer excellent strength-to-weight ratio, high tensile strength, and good resistance to chemicals and heat. One of the primary uses of glass fiber textiles in aerospace is for composite materials. These textiles are often used as reinforcement materials in composite structures, such as carbon fiber composites. The combination of glass fiber textiles with other materials in composites allows for the creation of lightweight yet strong components, such as aircraft wings, fuselage, and structural components. Glass fiber textiles are also used in the production of insulation materials for aerospace applications. Their excellent thermal insulation properties make them suitable for insulating spacecraft, satellites, and other aerospace vehicles. The textiles help to maintain stable internal temperatures, protect sensitive equipment from extreme heat or cold, and improve overall energy efficiency. Furthermore, glass fiber textiles have good electrical insulation properties, which are crucial for aerospace applications. They can be used to create protective covers for wiring and electrical components in aerospace vehicles, ensuring electrical safety and preventing interference. In addition to their physical properties, glass fiber textiles are relatively easy to manufacture, cost-effective, and readily available. These factors make them a preferred choice for aerospace applications, where reliability, performance, and cost-efficiency are essential. Overall, glass fiber textiles are well-suited for aerospace applications due to their strength, lightweight nature, thermal insulation properties, electrical insulation capabilities, and cost-effectiveness. Their use in composite materials and insulation systems contributes to the development of safer, more efficient, and technologically advanced aerospace vehicles.

- Q:How do glass fiber textiles affect the dimensional stability of fabrics?

- Glass fiber textiles can significantly improve the dimensional stability of fabrics. The incorporation of glass fibers into the fabric structure enhances its resistance to stretching, shrinking, and distortion. This increased stability is due to the high tensile strength and low elasticity of glass fibers, which help to maintain the shape and structure of the fabric even under various stress conditions.

- Q:How are glass fiber textiles different from other types of textiles?

- Glass fiber textiles are different from other types of textiles primarily because of the material they are made from. While most textiles are produced from natural fibers like cotton, silk, or wool, glass fiber textiles are made from synthetic fibers composed of glass. One key difference between glass fiber textiles and other textiles is their strength and durability. Glass fibers are known for their high tensile strength, meaning they can withstand a significant amount of tension without breaking. This makes glass fiber textiles ideal for applications that require strength and stability, such as reinforcement materials in composites or industrial fabrics. Glass fiber textiles also have excellent heat resistance properties. Unlike natural fibers that can burn or melt when exposed to high temperatures, glass fibers are able to withstand extreme heat without losing their structural integrity. This makes glass fiber textiles suitable for applications in high-temperature environments, such as insulation materials or protective clothing for firefighters. Another significant difference is the transparency of glass fiber textiles. Due to the nature of the glass material, these textiles can be made to have varying levels of transparency or translucency. This makes them suitable for applications like window coverings or curtains where a certain amount of light transmission is desired. In addition, glass fiber textiles are also highly resistant to chemical corrosion. They are not affected by most chemicals, acids, or alkalis, making them a preferred choice in industries like chemical processing or wastewater treatment. However, it is worth noting that glass fiber textiles may not be as comfortable or flexible as natural fiber textiles. Due to their synthetic nature, glass fibers can be stiffer and less breathable. This makes them less suitable for applications like clothing or bedding, where comfort and softness are important factors. Overall, glass fiber textiles offer unique properties that differentiate them from other types of textiles. Their strength, heat resistance, transparency, and chemical resistance make them valuable for a wide range of industrial and specialized applications.

- Q:How is glass fiber textile made?

- Glass fiber textile is made through a process called fiberglass manufacturing. It begins with melting a mixture of silica sand, limestone, and soda ash at extremely high temperatures. The molten glass is then forced through tiny holes in a device called a spinneret, creating thin strands of glass fibers. These fibers are then coated with a sizing material to improve their strength and flexibility. Finally, the fibers are gathered together to form yarns, which can be woven or knitted into various glass fiber textiles.

- Q:Can glass fiber textiles be used for making sporting goods or equipment?

- Yes, glass fiber textiles can be used for making sporting goods or equipment. Glass fiber textiles, also known as fiberglass, are lightweight and have high strength-to-weight ratio, making them suitable for various sports applications. They are commonly used in the production of sports equipment such as tennis rackets, golf club shafts, hockey sticks, and fishing rods. The unique properties of glass fiber textiles, including their durability, flexibility, and resistance to moisture and corrosion, make them ideal for withstanding the demands of sporting activities. Additionally, glass fiber textiles can be molded into different shapes and designs, allowing manufacturers to create customized and high-performance sporting goods. Overall, glass fiber textiles are a popular choice in the sports industry due to their excellent mechanical properties and versatility.

- Q:Can glass fiber textile be used in medical applications?

- Yes, glass fiber textile can be used in medical applications. It is commonly used in the manufacturing of medical devices such as wound dressings, surgical gowns, and orthopedic casts. The high strength and durability of glass fiber make it suitable for these applications, providing support and protection to patients. Additionally, glass fiber textiles can also be sterilized easily, making them a hygienic choice for medical use.

- Q:How does glass fiber textile perform in terms of water absorption?

- Glass fiber textile has extremely low water absorption properties. It is highly resistant to water absorption, meaning it does not retain or hold significant amounts of water.

- Q:Can glass fiber textile be used in concrete reinforcement?

- Certainly! Glass fiber textile, also referred to as glass fiber fabric or GFRP, possesses the capability to serve as a reinforcement material in concrete. This lightweight and high-strength substance effectively enhances the mechanical characteristics of concrete. Incorporating glass fiber textile within concrete aids in augmenting its tensile strength, flexural strength, and impact resistance, thereby bolstering its durability and crack resistance. Furthermore, this material exhibits corrosion resistance and does not rust, resulting in an extended lifespan for concrete structures. Consequently, it finds wide-ranging application in diverse scenarios, including precast concrete panels, beams, columns, and slabs.

- Q:Can glass fiber textiles be used for making protective helmets or headgear?

- Yes, glass fiber textiles can be used for making protective helmets or headgear. Glass fiber textiles are lightweight yet strong, making them ideal for protective gear such as helmets. The fibers are woven together to create a durable and impact-resistant material that can help absorb and distribute the force of an impact, thereby reducing the risk of head injuries. Additionally, glass fiber textiles have good heat resistance and insulation properties, which further enhance their suitability for headgear. However, it is important to note that helmets and headgear should comply with relevant safety standards and regulations to ensure maximum protection.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Micropore Insulation Board ,Heat Insulation materials

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 100 m²

- Supply Capability:

- 10000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords