Melamine Paper Faced MDF Board Wood Grain Color

- Loading Port:

- Lianyungang

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1000 pc

- Supply Capability:

- 50000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description:

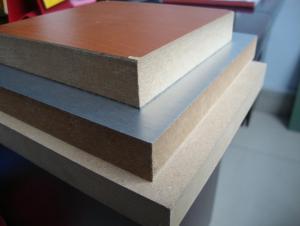

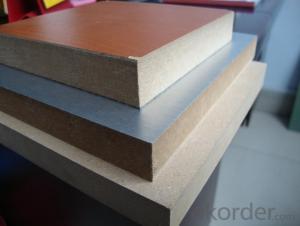

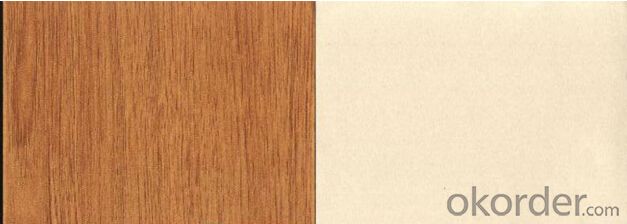

Melamine MDF with high quality paper and high quality MDF core . Melamine MDF can be applied to make kitchen cabinet, wardrobe, cupboard, bathroom cabinet and decoration, etc. There are rich color designs for options including woodgrain, solid color. Surface texure can make as quest from Customer

.

Specification :

1.application: furniture, door and decoration etc

2.core: MDF

3.face: melamine impregged film

4. size: 1220x2440mm; 1830x2440mm

5. thickness: 2-25mm

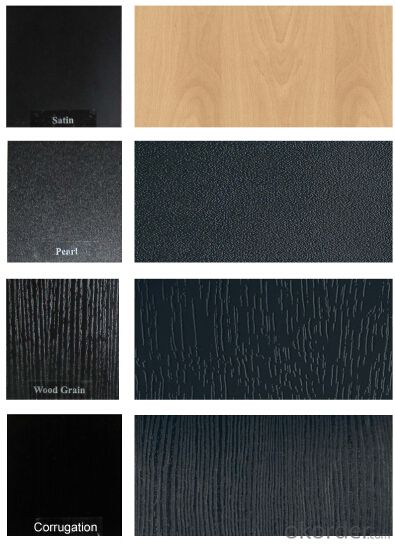

6.texutre of surface: satin, pearl, wood grain or as request

7 formaldehyde emission rate: E2, E1 OR CARB P2

Surface Textures:

Sample of color designs:

FAQ:

① why from okorder?

Okorder is a qualified supplier of all kinds of building matierials in China. All products have been showed in Okorder website are under well controlled by okorder QC team.

All products had been produced under a clear quality standard and the quality is consistence among the shipments.

Okorder has already setted up more than 20 warehouses in different markets to show the products. You are convenient to know the products from your local place and it will help you to make decision easyly.

②How to guarantee the quality of the products?

We have established a perfect quality management system,as for raw material and semi parts all are under strict quality test and we have a IQC system to control the purchases.

QC on site is very strict and all steps of process are measured per drawings. Before delivery, we set a OQC system to make sure each piece meet the standard of order.from design to delivery,

③How long can we receive the product after purchase?

Lead time depending on order quanity, The normal order can be deliveried with 3 weeks.

- Q:Embossed drawing veneer

- Texture and three-dimensional sense of strong, not easy to deformation. Embossed drawing panel gives the feeling of a more texture, especially for the interior decoration style in recent years.

- Q:Melamine plywood (do board with the board) dirty how to clean

- High-end cabinets, it is best to use a little better paper, good stain resistance.

- Q:What are the types and usage of interior panels?

- Decorative panels are widely used in the wall, the pillars, furniture, Pass, door, door sets of goods to the site after the use of the best brush before the first varnish to prevent contamination of the board, the need to discuss with the construction manager, A lot of team paint the color of the different methods, some want to color on the floor first, will have been on the varnish after the bad and then the color.

- Q:What kind of glue when you use it?

- Wood latex and Wan Nengjiao, (latex is mainly used for the connection of two materials to prevent deformation. Universal glue first with less, and now furniture are like custom. Are mixed oil)

- Q:What are the advantages of ecological boards and other boards?

- Consumers in the selection of such plate furniture, in addition to taking into account the color and texture satisfaction, but also from several aspects to identify the appearance of quality: whether stains, scratches, indentation, porosity, color gloss is not uniform, there is no Bubbling phenomenon, with or without local paper tear or defect phenomenon and so on. If the phenomenon of veneering cracking or damage, you can use the following methods to repair: first in the damaged place to put a damp cloth, and then put a hot iron on the hot cloth, forcing the moisture into the veneer, so that the veneer becomes tough and difficult Fragmentation. So that you can first clean the old plastic, and then coated with a layer of milk at the grass layer of wood, and then in the loose surface of the negative coated with a layer of new plastic, compaction, to be completely dry glue.

- Q:What is the particleboard veneer

- Mainly used in furniture and construction industry and trains, car manufacturing.

- Q:Is there a difference between paint and plywood?

- There are differences between paint panels and paint-free panels. Since the surface of the board is handled at the factory, it is more environmentally friendly than the decorative plates of the paint, and the quality of the paint is relatively good, and the finished paint-free board is cheaper than the decorative board + on-site paint combination.

- Q:What is the thickness of the trim panel?

- Decorative panel specifications commonly used 2440mm * 1220mm, 1000mm * 2000mm, 1220mm * 2000mm, 1200mm * 3000mm.

- Q:What is the difference between solid wood veneer doors and solid wood composite doors?

- Paint inside the door as long as the brand inside the door are solid wood, the price is more expensive, the outside pressure is the high density board less than 6 mm, the density board is better, on the outside of the tree is the skin of the general door are 3 thick, brand doors are at least six thick, the difference lies in the material, and processing technology, technology is not reached, then also white pull

- Q:White European furniture oak veneer good or smooth look good

- Veneer, then there will be lines. The And the general plywood will be clear water paint, a long time will be more and more oxidation of yellow. The The If you want European-style white, then it is recommended to do paint. The Put the putty on the wooden furniture and dry it with sandpaper. And then on the paint so even if the long time the oxidation of the furniture surface is white light. The

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Melamine Paper Faced MDF Board Wood Grain Color

- Loading Port:

- Lianyungang

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1000 pc

- Supply Capability:

- 50000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords