Manufacture Of Geocell

- Loading Port:

- Qingdao Port

- Payment Terms:

- TT or L/C

- Min Order Qty:

- 10000m2 m²

- Supply Capability:

- 450 million Per Year m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

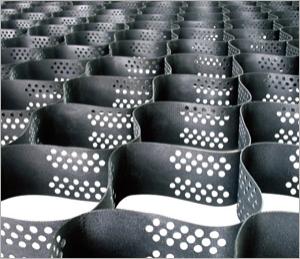

Introduction of Geocell:

CMAX Geocell is manufactured by quality HDPE material, has good performance on Anti-aging, resisting acid & alkaline, homogenous structure, best sidewise restriction and soil-fixation, convenient and fast construction.

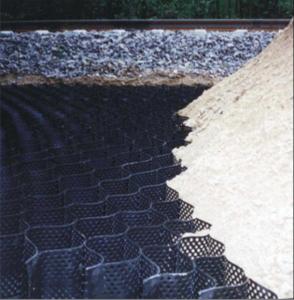

Applications of Geocell:

Make reinforcement treatment for soft soil foundation and protection of steep slope, used in highway, railway, airport, wharf, especially in air slaked mountain, desert and swamp land etc.

Specification of Geocell:

Model | Height(mm) | Welding Distance(mm) | Thickness(mm) | Tensile Strength of Welding point(N/cm) | Tensile Strength of the Geocell(N/cm) | Tensile Strength at Yield of Sheet(N/mpa) |

50-400 | 50 | 330-1000 | 1.1/1.2/1.5 | 100 | 120 | 20 |

75-40 | 75 | 330-1000 | 1.1/1.2/1.5 | 100 | 120 | 20 |

100-400 | 100 | 330-1000 | 1.1/1.2/1.5 | 100 | 120 | 20 |

150-400 | 150 | 330-1000 | 1.1/1.2/1.5 | 100 | 120 | 20 |

200-400 | 200 | 330-1000 | 1.1/1.2/1.5 | 100 | 120 | 20 |

Note: Customer could choose the suitable width, height, thickness etc. when the order confirmed | ||||||

- Q:Are geocells suitable for use in rail embankment construction?

- Yes, geocells are suitable for use in rail embankment construction. Geocells provide effective soil stabilization, erosion control, and load distribution, making them ideal for reinforcing embankments and preventing slope failures. They offer increased stability, reduced settling, and improved overall performance, making them a reliable and cost-effective solution for rail embankment construction projects.

- Q:What are the applications of geocells?

- Geocells have various applications in civil engineering and construction projects. They are commonly used for soil stabilization, erosion control, slope protection, and retaining wall construction. Geocells also find applications in road and railway construction, as well as in building foundations and landfill lining systems.

- Q:Can geocells be used for pipeline trench backfill?

- Yes, geocells can be used for pipeline trench backfill. Geocells are a type of cellular confinement system made from high-density polyethylene (HDPE) material. They are designed to provide structural support and stability to soil, preventing erosion and lateral movement. When used for pipeline trench backfill, geocells can help distribute the load evenly, reduce settlement, and enhance the overall strength of the backfill material. Additionally, geocells promote efficient drainage and allow for the growth of vegetation, further improving the long-term performance of the pipeline.

- Q:Can geocells be used in railway ballast confinement?

- Yes, geocells can be used in railway ballast confinement. Geocells provide a reliable and cost-effective solution for stabilizing and confining ballast in railway tracks. They help distribute loads evenly, prevent lateral movement, and reduce track settlement, resulting in improved track stability and longevity.

- Q:Are geocells resistant to hydraulic pressure?

- Yes, geocells are generally resistant to hydraulic pressure. The cellular structure of geocells allows them to withstand significant hydraulic pressure, making them an effective solution for erosion control, soil stabilization, and slope protection in various applications.

- Q:Can geocells be used in underground cable protection systems?

- Yes, geocells can be used in underground cable protection systems. Geocells are cellular confinement systems made of interconnected cells that can be filled with various materials like soil or aggregate. These cells provide structural support, erosion control, and can effectively protect underground cables from damage caused by external factors such as ground movement, vehicle traffic, and environmental conditions. The use of geocells in underground cable protection systems improves the overall stability and longevity of the cables, ensuring reliable and uninterrupted power supply.

- Q:Are geocells resistant to root penetration?

- Yes, geocells are resistant to root penetration. They are typically made from high-density polyethylene (HDPE) material, which is strong and durable, preventing roots from penetrating through the geocell structure. This makes geocells an effective solution for preventing root intrusion in various applications, such as landscaping, road construction, and erosion control.

- Q:Can geocells be used in bridge approach construction?

- Yes, geocells can be used in bridge approach construction. Geocells are a type of geosynthetic material that can provide stabilization and reinforcement to soil and aggregate materials. By using geocells in bridge approach construction, the soil can be effectively confined, preventing lateral spreading and improving load-bearing capacity. This helps in preventing settlement, erosion, and maintaining the stability of the bridge approach. Geocells also offer advantages such as cost-effectiveness, ease of installation, and long-lasting performance, making them a suitable choice for bridge approach construction projects.

- Q:Can geocells be used in green roof systems?

- Yes, geocells can be used in green roof systems. Geocells provide structural support while allowing for the growth of vegetation, making them an ideal solution for creating green roofs that are both durable and eco-friendly.

- Q:How do geocells improve the performance of pavements?

- Geocells improve the performance of pavements by providing reinforcement and stabilization to the base materials. The honeycomb-like structure of geocells confines and reinforces the infill material, preventing lateral movement and increasing load-bearing capacity. This results in enhanced pavement strength, reduced rutting and cracking, improved longevity, and better overall performance.

1. Manufacturer Overview |

|

|---|---|

| Location | Shandong, China |

| Year Established | 2000 |

| Annual Output Value | Above US$ 20 Million |

| Main Markets | North America; South America; Eastern Europe; Southeast Asia; Africa; Oceania; Mid East; Eastern Asia; Western Europe; Central America; |

| Company Certifications | ISO 9001:2000 |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | Qingdao Port |

| Export Percentage | 41% - 50% |

| No.of Employees in Trade Department | Above 10 People |

| Language Spoken: | English; Chinese; |

| b)Factory Information | |

| Factory Size: | Above 17,0000 square meters |

| No. of Production Lines | Above 10 |

| Contract Manufacturing | Design Service Offered; Buyer Label Offered |

| Product Price Range | High; Average |

Send your message to us

Manufacture Of Geocell

- Loading Port:

- Qingdao Port

- Payment Terms:

- TT or L/C

- Min Order Qty:

- 10000m2 m²

- Supply Capability:

- 450 million Per Year m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords