Hot Rolled Steel Plate SS400 Made In China

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Item specifice

GRADE:

SS400, ASTM A36, A572, ST37,ST52, Q195, Q215, Q235,Q345, S235JR etc.

STANDARD:

GB/T709-2006, ASTM A36, JIS G3101, DIN EN 10025, SAE 1045, ASTM A570

SPEC:

1) Width: 600-2500mm or 1000,1050,1250,1500,1800,2000mm

2) Thickness:1.5mm-200mm or as customers’ special requirements

3) Length: 2-12m or as customers’ special requirements

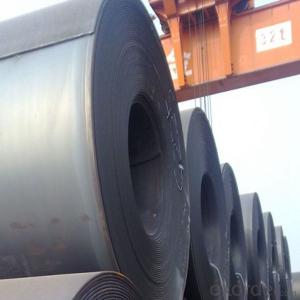

DETAILED PICTURES FOR STEEL COILS

PACKAGING &DELIVERY FOR STEEL COILS/SHEETS

Packaging Detail Standard export packing or following customer's demand

Delivery Time: Within 30-40 days after deposit or according to the order quantity

OUR SERVICE

1.High quanlity and reasonable price.

2.Customized on-demand.

3.Reasonable shipping and fast delivery.

4.Free sample.

FAQ

Q: How long is the delivery time?

A: Normally 30-40 days, but mostly according to the specific requirements or the quantity

Q: How can I get the samples?

A: If you need some samples to test ,please pay for the transportation freight of samples and our samples are free for you.

Q: How can I get your price list?

A: Please send us your email or fax and order information – Quantity, Specification (steel type, thickness, width, surface finish), then I can send you the price list.

- Q:What are the different hardness levels available for steel sheets?

- There are various hardness levels available for steel sheets, typically classified using the Rockwell hardness scale. Some common hardness levels for steel sheets include HRC (Rockwell C), HRB (Rockwell B), HV (Vickers hardness), and HRA (Rockwell A). These different hardness levels determine the steel sheet's resistance to indentation or deformation, allowing it to be suitable for specific applications.

- Q:Can steel sheets be used for shipbuilding?

- Yes, steel sheets can definitely be used for shipbuilding. In fact, steel is one of the most commonly used materials in shipbuilding due to its excellent strength, durability, and resistance to corrosion. Steel sheets are typically used to construct the hull, decks, and other structural components of a ship. The high tensile strength of steel allows ships to withstand the harsh conditions of the ocean, including heavy waves and extreme weather. Additionally, steel sheets can be easily fabricated and welded together, making them ideal for constructing large and complex ship structures. Overall, steel sheets are a reliable and efficient choice for shipbuilding.

- Q:Can steel sheets be used for manufacturing signage or advertising boards?

- Yes, steel sheets can be used for manufacturing signage or advertising boards. Steel sheets are durable, weather-resistant, and can be easily customized with various finishes and coatings. They provide a sturdy base for signage and can withstand outdoor elements, making them a popular choice for outdoor advertising.

- Q:Can steel sheets be customized in terms of thickness?

- Indeed, thickness customization is possible for steel sheets. Steel sheets are produced in a variety of thicknesses to accommodate diverse applications and demands. The manufacturing process allows for the customization of a steel sheet's thickness based on the customer's specific requirements. This customization feature provides versatility and adaptability, enabling steel sheets to be utilized across a broad spectrum of industries such as construction, automotive, manufacturing, and fabrication. By tailoring the thickness of steel sheets, they can effectively fulfill the precise needs for strength, durability, and structural integrity in any given project.

- Q:Do steel sheets require any surface treatment before installation?

- Yes, steel sheets generally require surface treatment before installation to prevent corrosion, improve paint adhesion, and enhance their overall durability and longevity. Common surface treatments include cleaning, degreasing, priming, and applying protective coatings such as galvanizing or powder coating.

- Q:What is the average thickness of steel sheets?

- The average thickness of steel sheets varies depending on the specific application and industry. However, common thicknesses range from 0.4 mm to 6 mm for general purposes, while thicker sheets can go up to 25 mm or more for specialized uses.

- Q:What are the different sheet metal cutting techniques for steel sheets?

- There are several different sheet metal cutting techniques that can be used for steel sheets. Some of the most common methods include shearing, laser cutting, plasma cutting, and waterjet cutting. Shearing involves the use of a mechanical shear to cut the steel sheet along a straight line. Laser cutting uses a high-powered laser beam to melt and vaporize the steel, creating a precise and clean cut. Plasma cutting utilizes a plasma torch to heat and melt the steel, while a high-velocity jet of ionized gas blows the molten metal away. Waterjet cutting involves the use of a high-pressure stream of water mixed with abrasive particles to erode and cut through the steel sheet. Each technique has its own advantages and limitations, depending on factors such as the thickness of the steel, desired precision, and cost considerations.

- Q:How can steel sheets be protected from corrosion?

- Steel sheets can be protected from corrosion through various methods such as applying protective coatings, using corrosion-resistant alloys, galvanizing the steel, or implementing cathodic protection techniques.

- Q:Can steel sheets be heat treated for increased hardness?

- Steel sheets have the capability to undergo heat treatment in order to enhance their hardness. Heat treatment serves as a method to modify the physical and mechanical properties of steel, specifically hardness. The most commonly employed heat treatment technique for augmenting the hardness of steel sheets is known as quenching and tempering. Throughout this process, the steel sheets are subjected to high temperatures and then rapidly cooled by quenching in a suitable medium, such as oil or water. This rapid cooling facilitates the alteration of the steel's microstructure, ultimately resulting in increased hardness. However, it is worth noting that this abrupt cooling may also introduce internal stresses to the steel, rendering it brittle. To counteract this brittleness, the quenched steel sheets are subsequently tempered by reheating them to a specific temperature and maintaining this temperature for a designated period. Tempering enables the steel to regain some of its ductility while still retaining the desired hardness. It is crucial to acknowledge that the precise heat treatment process and parameters employed for steel sheets are contingent upon the composition and intended application of the steel. Different steel alloys necessitate distinct heat treatment procedures, and as a consequence, the temperature and time parameters may vary accordingly. Consequently, it is vital to seek advice from an expert or refer to the steel's technical specifications to ascertain the appropriate heat treatment process for achieving the desired hardness.

- Q:Are steel sheets suitable for noise barriers or soundproofing?

- Yes, steel sheets can be suitable for noise barriers or soundproofing. Steel is a dense material that effectively blocks and absorbs sound waves, making it an effective choice for reducing noise transmission. Additionally, steel sheets can be designed to have different thicknesses and textures to further enhance their soundproofing capabilities.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Hot Rolled Steel Plate SS400 Made In China

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords