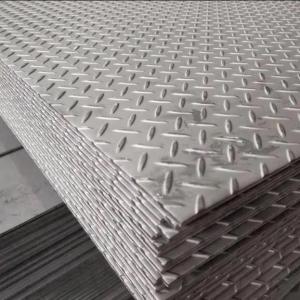

Hot Rolled Steel Chequered Skid Resistance Sheets Chequer Plates

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Hot Rolled Steel Chequered

The steel surface with a pattern called chequered, its pattern into lentil-shaped, diamond, round bean-shaped, oblate shape mixed.

Features

Checkered appearance, can slip, strengthen performance, saving steel and many other advantages.

In transportation, construction, decoration, floor surrounding equipment, machinery, shipbuilding and other fields have a wide range of applications.

Generally, parties to checkered mechanical properties, mechanical performance requirements, so checkered pattern quality mainly as flowering rate, the pattern height, elevation pattern.

Currently on the market common thickness ranging from two kinds of width are common 1250,1500mm from 2.0-8mm.

Specifications

1. Plate width 600 ~ 1800mm, 50mm press upgrade; length of 2000 ~ 12000mm, press the 100mm upgrade.

2. High grain pattern is not less than 0.2 times the thickness of the substrate. Size does not figure as a finished check basis.

3. Plate steel grades according to GB / T700, GB / T712, GB / T4171 requirements.

4. Mechanical properties of steel does not guarantee, when required by the demand side, according to standard regulations, but also by mutual agreement.

5. Hot-rolled steel sheet delivery.

Pictures

- Q:What is the difference between a smooth and expanded metal steel sheet?

- A smooth steel sheet refers to a flat surface without any visible patterns or perforations. It is typically used in applications where a sleek appearance is desired, such as in architectural or decorative purposes. Smooth steel sheets are commonly used for countertops, backsplashes, and wall coverings. On the other hand, an expanded metal steel sheet is created by cutting and stretching a solid sheet of steel to create a pattern of interconnected diamond-shaped openings. This process enhances the structural integrity of the sheet while allowing for increased airflow, visibility, and drainage. Expanded metal steel sheets are commonly used in industrial and construction applications, such as walkways, grating, fencing, and machine guards. The main difference between a smooth and expanded metal steel sheet lies in their appearance, functionality, and intended applications. Smooth steel sheets offer a clean and polished look, while expanded metal steel sheets provide strength, ventilation, and versatility. Ultimately, the choice between the two depends on the specific requirements of the project at hand.

- Q:How do steel sheets perform in fire-rated applications?

- Steel sheets perform exceptionally well in fire-rated applications. Due to their high melting point and excellent heat resistance, they offer superior protection against fire and help to contain its spread. Steel sheets are widely used in fire-rated walls, doors, and ceilings, as they maintain their structural integrity even at extremely high temperatures. Additionally, they contribute to fire safety by limiting the release of toxic gases and smoke, making them a reliable choice for fire protection in various industries and buildings.

- Q:What is the thickness range for steel sheets?

- The thickness range for steel sheets typically varies from 0.4 millimeters to 6 millimeters, depending on the specific application and industry requirements.

- Q:Are steel sheets suitable for flooring applications?

- Yes, steel sheets are suitable for flooring applications. Steel sheets offer many advantages that make them an ideal choice for flooring. Firstly, steel sheets are extremely durable and can withstand heavy loads and high foot traffic. They are resistant to wear and tear, making them long-lasting and cost-effective in the long run. Additionally, steel sheets are fire-resistant, which enhances the safety of the flooring. They are also resistant to moisture, making them suitable for areas with high humidity or where water may be present. Furthermore, steel sheets are easy to clean and maintain, requiring minimal effort and cost for upkeep. They are available in a variety of sizes, thicknesses, and finishes, allowing for customization to suit different flooring requirements. Overall, steel sheets offer a strong, durable, and versatile flooring option that can be used in various applications, including industrial, commercial, and residential settings.

- Q:How are steel sheets protected during storage in outdoor environments?

- Steel sheets in outdoor environments are often protected through various measures. One effective technique involves applying a protective coating onto the surface of the sheets. This coating serves as a barrier, preventing direct contact between the steel and moisture or other environmental factors. It can take the form of paint, varnish, or a specialized substance that resists corrosion. Additionally, to provide an extra layer of protection, steel sheets can be covered with plastic wrap or a tarpaulin. This shields them from rain, snow, and other weather conditions that could potentially lead to rust or corrosion. Moreover, proper stacking and storage techniques play a crucial role in safeguarding steel sheets. It is important to store them in a dry and well-ventilated area, preferably on pallets or racks to keep them off the ground. Ample space between the stacks allows for air circulation, minimizing the risk of moisture accumulation. Regular maintenance and inspection are vital to ensure continuous protection of steel sheets in outdoor storage. The protective coating should be periodically examined for any signs of damage or wear, and any necessary touch-ups or reapplications should be promptly carried out. By implementing these protective measures, steel sheets can be shielded from the harsh elements commonly found in outdoor environments. This guarantees their longevity and preserves their quality.

- Q:What are the limitations of using steel sheets?

- There are several limitations associated with using steel sheets in various applications. Firstly, steel sheets are relatively heavy compared to other materials, which can pose challenges in terms of transportation and installation. This weight can also limit their use in applications where weight reduction is critical, such as aerospace or automotive industries. Secondly, steel sheets are susceptible to corrosion, especially when exposed to moisture and chemicals. If not properly protected, this can lead to rusting and a decrease in structural integrity over time. Therefore, additional coatings or treatments are often required to prevent corrosion, adding to the overall cost and maintenance requirements of steel sheet usage. Another limitation is that steel sheets have limited flexibility and cannot be easily molded or shaped into complex forms. This restricts their use in applications where intricate designs or curved surfaces are required, such as in the construction of curved roofs or architectural structures. Furthermore, steel sheets have poor thermal insulation properties, meaning they conduct heat and cold more readily than other materials. This can result in temperature fluctuations and energy loss in buildings, requiring additional insulation measures to maintain thermal comfort and energy efficiency. Lastly, steel sheets are a finite resource and their production can have a significant environmental impact. The extraction of raw materials, energy consumption, and carbon emissions associated with steel production make it less sustainable compared to alternative materials. In summary, while steel sheets are widely used for their strength and durability, their limitations include their weight, susceptibility to corrosion, limited flexibility, poor thermal insulation properties, and environmental impact. These limitations should be considered when selecting materials for specific applications.

- Q:Can steel sheets be bent or curved?

- Yes, steel sheets can be bent or curved. Steel is a malleable material, meaning it can be easily shaped or formed without breaking or cracking. This property allows steel sheets to be bent or curved into various shapes and angles, depending on the desired outcome. The process of bending or curving steel sheets typically involves the use of specialized tools such as press brakes or rollers. These tools apply force to the steel sheet, causing it to bend or curve according to the desired specifications. This ability to manipulate steel sheets makes them highly versatile and widely used in industries such as construction, automotive, and manufacturing.

- Q:Can steel sheets be used for signage purposes?

- Indeed, signage purposes can be served by steel sheets. Their durability allows them to withstand harsh weather conditions, rendering them appropriate for outdoor signage. Various sizes and designs can be achieved by cutting, shaping, and welding the steel sheets, offering versatility in crafting personalized signage. To enhance aesthetics and ensure long-lasting quality, the steel sheets can be painted or coated with different finishes. Moreover, their sturdiness enables secure mounting, making them an excellent choice for large and heavy signage installations.

- Q:How are steel sheets packaged for shipping?

- Steel sheets are typically packaged for shipping in a way that ensures their protection during transportation. The packaging process involves various steps to prevent any damage or deformation that may occur during transit. Firstly, the steel sheets are usually stacked on wooden pallets or placed in sturdy steel crates. This helps to provide a stable base and prevents any movement or shifting of the sheets during transportation. The use of pallets or crates also makes it easier to load and unload the sheets onto trucks or containers. To further protect the steel sheets from scratches or other forms of surface damage, they are often covered with a layer of protective material. This can include plastic wraps, paper or cardboard interleaves, or even a layer of oil or rust inhibitor. These protective materials act as a barrier between the steel sheets, preventing any direct contact that may cause scratches. Additionally, steel sheets may be bundled together with steel strapping or wire to keep them securely in place. This bundling process helps to maintain the structural integrity of the sheets and prevents them from shifting or sliding during transportation. Finally, once the steel sheets are properly packaged, they are typically labeled with relevant information such as product specifications, quantity, and destination. This ensures that the sheets can be easily identified and handled correctly at each stage of the shipping process. Overall, the packaging of steel sheets for shipping is carefully done to ensure their safe and secure transportation. By using pallets or crates, protective materials, bundling, and labeling, steel sheets can withstand the rigors of shipping and arrive at their destination in optimal condition.

- Q:How are steel sheets protected during cutting and fabrication?

- Steel sheets are protected during cutting and fabrication through various methods to ensure their quality and prevent damage. One common way to protect steel sheets is by using a process called "galvanizing". Galvanizing involves applying a protective zinc coating to the surface of the steel sheet, which acts as a barrier against corrosion and other forms of damage. This process is particularly effective in outdoor environments where steel sheets are exposed to moisture and other harsh elements. Another method of protection during cutting and fabrication is the use of lubricants or coolants. These substances are applied to the cutting tools and the steel sheet itself to reduce friction and heat generation. By minimizing heat, lubricants and coolants help prevent the steel sheet from warping or distorting during the cutting and fabrication process. Furthermore, during the fabrication of steel sheets, they are often covered or masked with protective films or tapes. These films or tapes act as a shield against scratches, abrasions, and other forms of physical damage that may occur during handling or transportation. In addition to these methods, proper handling and storage practices are also crucial for protecting steel sheets during cutting and fabrication. Steel sheets should be stored in a controlled environment to prevent exposure to moisture, extreme temperatures, or other damaging elements. They should also be handled with care to avoid any impact or bending that could compromise their structural integrity. Overall, steel sheets are protected during cutting and fabrication through a combination of surface coatings, lubricants or coolants, protective films or tapes, and proper handling and storage practices. These measures help ensure the quality and durability of the steel sheets, allowing them to maintain their integrity throughout the fabrication process and beyond.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Hot Rolled Steel Chequered Skid Resistance Sheets Chequer Plates

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords