Hot Rolled Aluminum Gutter Coil CNBM Supplier

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

l Product Introduction

Hot Rolled Aluminum Gutter Coil CNBM Supplier is widely used in manufacturing aluminum thin sheet and aluminum foil. It is suitable for further machining with original standard quality. It is easy to be controlled and be manufactured to according to requirements.

1. Temper: O, F, HXX

2. Thickness: Thickness

3. Width: 1000-1500mm

4. Type: Coil/Roll

5. Surface Treatment: mill finished

6. Application: Decoration, packaging, printing, covering

7. Standard size: Upon customer's demand

8. Quantity: 18tons(±10%)in one 20 feet container

l Product Description

Specification:

Hot Rolled Aluminium coil | ||||||||||||||||

Aluminium Coils, non-alloy and alloy products have many different applications, they are used windly throughout construction, building, decoration, lighting, metal nameplate, aircraft and aerospace structures, etc. | ||||||||||||||||

Specification | ||||||||||||||||

ALLOY | TEMPER | THICKNESS | WIDTH(mm) | LENGTH(mm) | ||||||||||||

1050, 1060, 1070,1100, 1235,1200, ,3003,3005, | O, F, H12, H18, H22, H24,H26,H32, H34, H36, H111, H112, H314 | 3.0-10.0 | 1000--1500mm | in Coil | ||||||||||||

chemical composition | ||||||||||||||||

Alloy | Si | Fe | Cu | Mn | Mg | Cr | Ni | Zn | Ca | V | Ti | Other | Min.Al | |||

1050 | 0.25 | 0.40 | 0.05 | 0.05 | 0.05 | - | - | 0.05 | - | 0.05 | 0.03 | 0.03 | 99.50 | |||

1060 | 0.25 | 0.35 | 0.05 | 0.03 | 0.03 | - | - | 0.05 | - | 0.05 | 0.03 | 0.03 | 99.60 | |||

1070 | 0.20 | 0.25 | 0.04 | 0.03 | 0.03 | - | - | 0.04 | - | 0.05 | 0.03 | 0.03 | 99.70 | |||

1100 | 0.95 | 0.05-0.2 | 0.05 | - | - | - | 0.10 | - | - | - | 0.05 | 99.00 | ||||

3003 | 0.60 | 0.70 | 0.5-0.2 | 1.0-1.5 | - | - | - | 0.10 | - | - | - | 0.15 | 96.95-96.75 | |||

3004 | 0.30 | 0.70 | 0.25 | 1.0-1.5 | 0.8-1.3 | - | - | 0.25 | - | - | - | 0.15 | 96.55-95.55 | |||

l Packaging & Delivery

Packaging detail: Standard seaworthy exporting carton, Wooden pallets, waterproof paper and plastic coverage or as customer's requirements

Delivery detail: about 25 days from received oiginal L/C or advance payment

l Company Profile

CNBM International Corporation, China National Building Materials (Group) Corporation, is one of the largest companies in China building material & equipment industry, with 42,800 employees and sales in 2005 of US Dollar 4.395 billion. In 2006, China National Building Material Company Limited was listed on Hong Kong Stock Market with the stock code as 3323.

The business scope of CNBM covers from manufacturing and sales of a series of building materials to scientific research and design, import and export trade. In many of these fields, CNBM is playing the leading role.

l CNBM World Wide

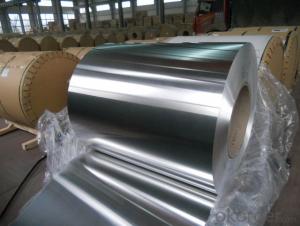

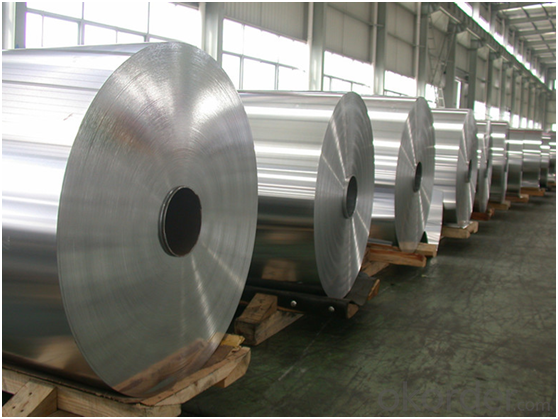

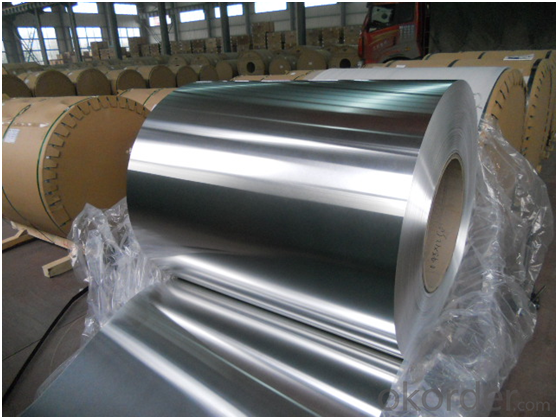

l Product Images

l Certificates

l FAQ

Q: Do you provide free samples?

A: Yes, free samples will be sent to you on freight at destination.

Q: Can I get your latest products catalogue?

A: Yes, it will be sent to you in no time.

Q: What is the MOQ?

A: 5 tons

Q: What are your payment terms?

A: We accept L/C, T/T.

l Contact Us

Email: service@okorder.com

- Q:I'm doing a project on aluminum and this is the one thing i can't find. Also will it rust, tarnish or corrode?

- Aluminum is not explosive, although in the presence of a suitable oxidizing agent it can burn. It does not rust (that concept applies only to ferrous metals), but can corrode and will tarnish rapidly if a cut surface is exposed to air. The tarnish, aluminum oxide, protects the surface from further oxidation, and a process called anodizing puts a heavy oxide layer on the surface for improved protection. Aluminum is produced by electrolysis from aluminum oxide, which is dissolved in molten aluminum fluoride; a typical electrolytic pot uses a current of 5 volts at 105,000 amperes and will produce a ton of aluminum per day.

- Q:Can aluminum coils be used in agricultural applications?

- Yes, aluminum coils can be used in agricultural applications. Aluminum is a versatile and lightweight material that offers several benefits for agricultural purposes. Aluminum coils are commonly used in various agricultural equipment and structures, such as greenhouse frames, irrigation systems, and grain storage bins. One of the main advantages of using aluminum coils in agricultural applications is their resistance to corrosion. Aluminum is naturally resistant to rust and can withstand exposure to moisture, chemicals, and other elements commonly found in agricultural environments. This makes it a durable and long-lasting choice for agricultural equipment that needs to withstand harsh conditions. Additionally, aluminum coils have excellent thermal conductivity, meaning they can efficiently transfer heat. This property makes aluminum coils suitable for applications such as heat exchangers, which are often used in agricultural machinery like tractors and combine harvesters. Efficient heat transfer helps in maintaining optimal operating temperatures and improving overall equipment performance. Moreover, aluminum coils are lightweight, which makes them easy to handle and transport. This is particularly advantageous in agricultural applications where equipment needs to be moved frequently, such as portable irrigation systems or lightweight structures. The lightweight nature of aluminum also helps reduce fuel consumption in machinery, leading to cost savings and environmental benefits. Furthermore, aluminum is a non-toxic material, making it safe to use in agricultural applications. It does not release any harmful chemicals or leach into the soil, ensuring that crops remain uncontaminated and safe for consumption. In summary, aluminum coils can indeed be used in agricultural applications due to their corrosion resistance, thermal conductivity, lightweight nature, and non-toxic properties. These qualities make aluminum a reliable and efficient choice for various agricultural equipment and structures, contributing to increased productivity and sustainability in the agricultural industry.

- Q:Can aluminum coils be used for architectural applications?

- Yes, aluminum coils can be used for architectural applications. Aluminum is a versatile and lightweight material that offers excellent corrosion resistance, making it suitable for various architectural purposes. Aluminum coils can be used for exterior cladding, roofing, facades, and even interior applications like ceilings and wall panels. The coils can be easily formed, cut, and shaped, allowing for flexibility in design and creative architectural solutions. Additionally, aluminum coils can be coated with various finishes, such as paint or anodized coatings, to provide enhanced aesthetics and durability. Overall, aluminum coils are a popular choice in the architectural industry due to their versatility, durability, and aesthetic appeal.

- Q:When you open an aluminum beverage can, do particles of aluminum get into the drink?

- No. Aluminum has metallic bonds, so atoms don't break off that easily.

- Q:Are aluminum coils suitable for solar reflectors?

- Yes, aluminum coils are indeed suitable for solar reflectors. Aluminum has high reflectivity, making it an ideal material to redirect and focus sunlight onto solar panels or other solar energy systems. Its lightweight nature and resistance to corrosion also make it a practical choice for solar reflectors.

- Q:What are the insulation options available for aluminum coils?

- There are various insulation options available for aluminum coils, including fiberglass insulation, foam insulation, and elastomeric insulation. These insulation materials help to improve the energy efficiency of the coils and prevent condensation or heat loss.

- Q:How do aluminum coils compare to magnesium coils in terms of strength?

- Aluminum coils generally have higher strength compared to magnesium coils. Aluminum is known for its excellent strength-to-weight ratio, making it a popular choice in various industries. It has a higher tensile strength and better resistance to deformation under stress compared to magnesium. Additionally, aluminum has a higher yield strength, which means it can withstand greater loads before experiencing permanent deformation. On the other hand, magnesium is lighter than aluminum, but it tends to have lower strength properties. While magnesium coils might be advantageous in some applications where weight is a critical factor, aluminum coils are generally preferred in terms of strength and durability.

- Q:my text says aluminium does not corrode much as a passive aluminium oxide layer is formed on it.Well other metals such as sodium adn potassium also form oxides. Why dont their oxides prevent further oxidation ?

- Not sure. Maybe because Na K are more active than Aluminum.

- Q:How are aluminum coils used in the electrical industry?

- Aluminum coils are widely used in the electrical industry for various applications such as transformers, motors, generators, and electrical transmission systems. These coils are used to create electromagnetic fields, which are essential for the functioning of these electrical devices. Additionally, aluminum coils are preferred due to their lightweight, high thermal conductivity, and cost-effectiveness compared to other materials.

- Q:What are the width tolerances for aluminum coils?

- The width tolerances of aluminum coils can differ based on the specific application and industry standards. Generally, the typical range for standard width tolerances is between +/- 0.005 inches to +/- 0.020 inches. These tolerances guarantee that the width of the aluminum coil remains within an acceptable range and meets the necessary dimensions for the intended use. It is important to mention that tighter tolerances may be attainable depending on the manufacturing processes and equipment capabilities. Thus, consulting the appropriate industry standards and specifications is crucial in determining the precise width tolerances needed for a specific application.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Hot Rolled Aluminum Gutter Coil CNBM Supplier

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords