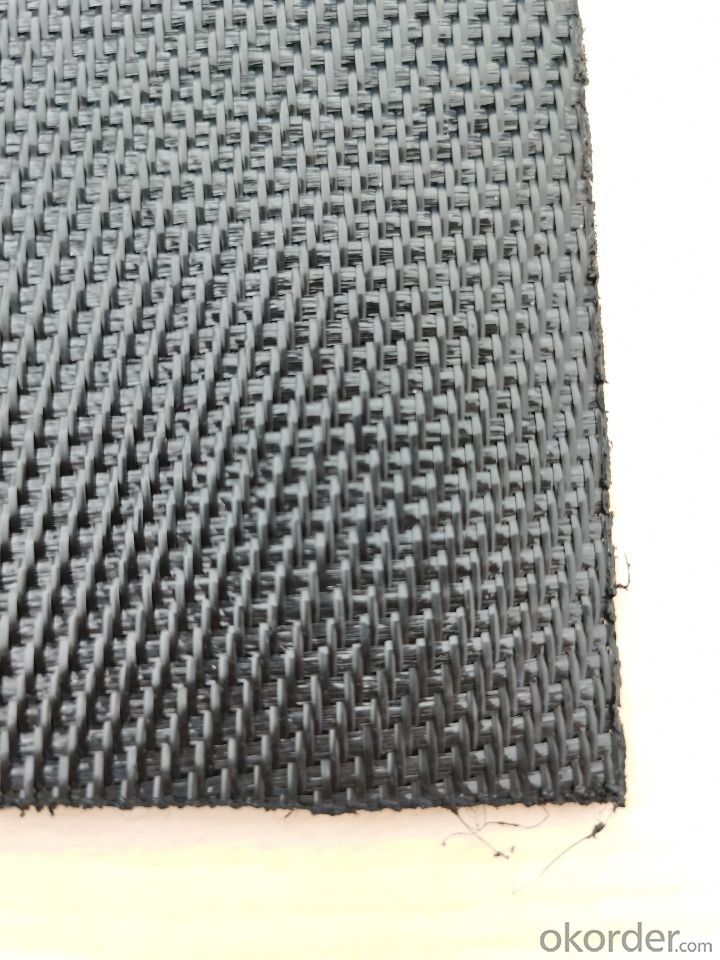

High Strength Woven Geotextile for Road Construction Use

- Loading Port:

- Qingdao

- Payment Terms:

- TT or LC

- Min Order Qty:

- 20000 m²

- Supply Capability:

- 200000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

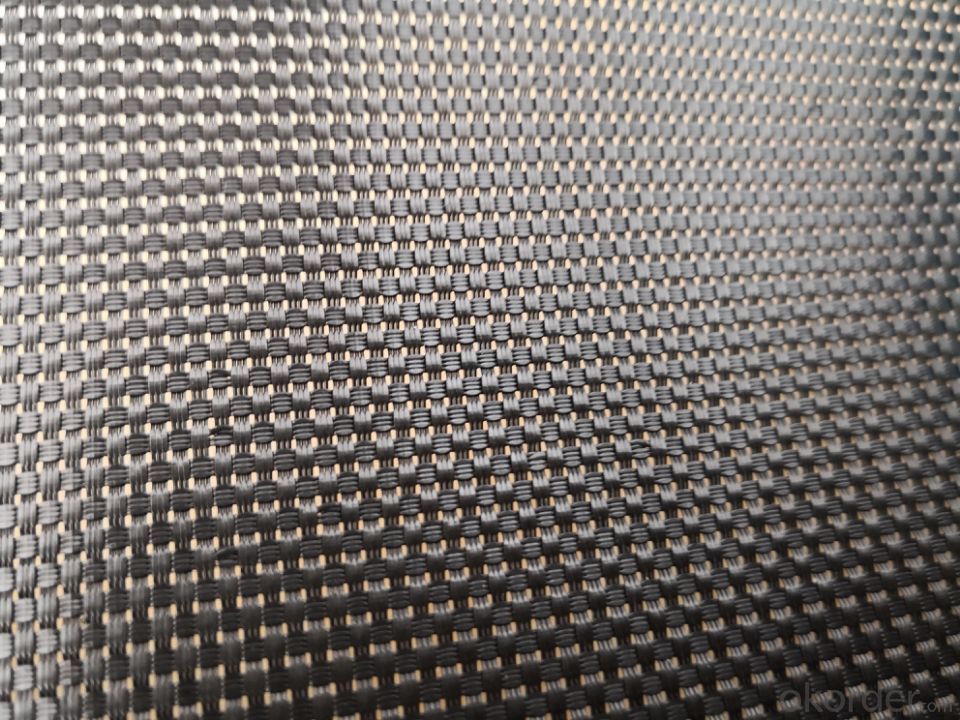

High Strength PP Woven Geotextile

1. Description of High Strength PP Woven Geotextile

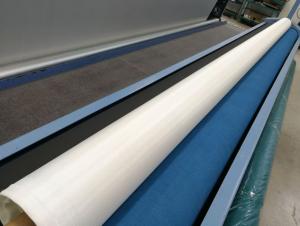

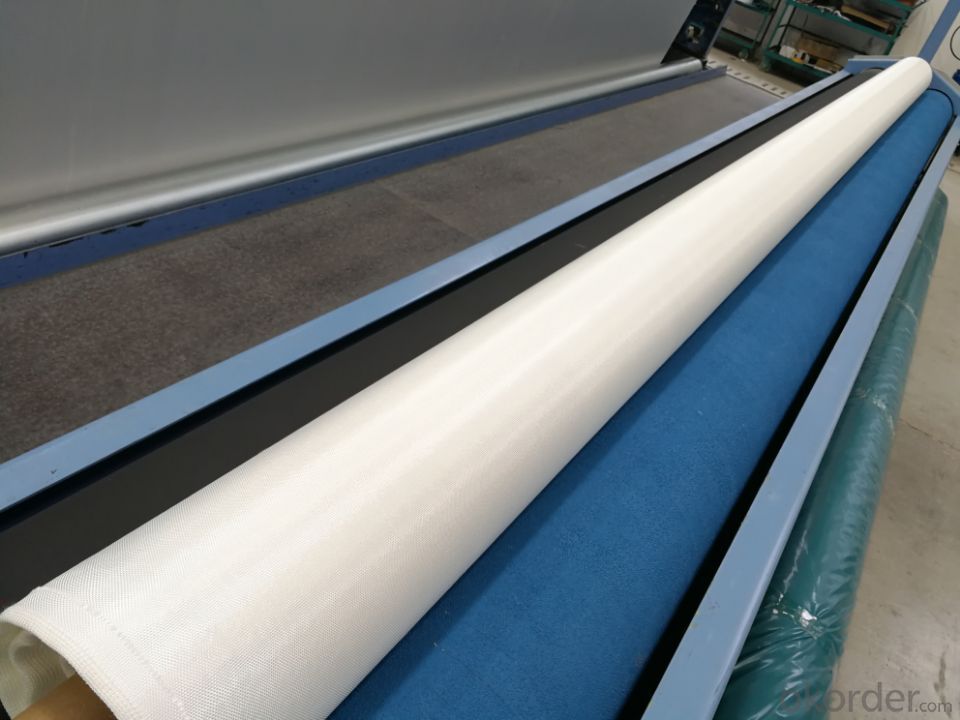

CMAX polypropylene woven geotextile is made from polypropylene flit yarn on circle weave machine, including circular loom and flat loom.

2. Specification of High Strength PP Woven Geotextile

Weight: 90gsm – 400gsm;

Width: 1m – 6m; Length: as clients’ required.

3. Technical Data Sheet of High Strength PP Woven Geotextile

Item | Unit | Index | ||||||

Unit Weight | g/m2 | 120 | 160 | 200 | 240 | 280 | 340 | 400 |

Breaking Strength in MD | KN/m | 20 | 30 | 40 | 50 | 60 | 80 | 100 |

Breaking Strength in CD | KN/m | 15 | 22 | 28 | 35 | 42 | 56 | 70 |

Elongation Rate | % | 25 | ||||||

Trapezoidal Tearing Strength | KN | 0.2 | 0.27 | 0.34 | 0.41 | 0.48 | 0.6 | 0.72 |

CBR Mullen Burst Strength | KN | 1.6 | 2.4 | 3.2 | 4.0 | 4.8 | 6.0 | 7.5 |

Vertical Permeability | Cm/s | 10^-1 ~10^-4 | ||||||

Sieve Size O90(O95) | Mm | 0.07 ~ 0.50 | ||||||

Variation | % | ±10 | ||||||

4. Property of High Strength PP Woven Geotextile:

1).Light weight, high strength, low elongation, easy to construct.

2).Reinforcement, separation, drainage and filtration, fencing function.

5. Application of High Strength PP Woven Geotextile

Railways, highways, sport fields, earthwork projects, tunnels, coal mines, walls and slopes, environmental protection and so on.

.

High Strength PET Woven Geotextile

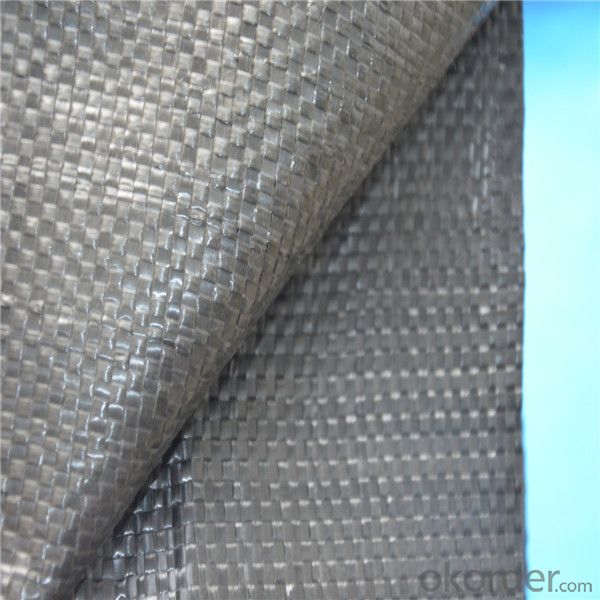

1. Description of PET Woven Geotextile

CMAX filament woven geotextile is made from polypropylene, high strength industrial synthetic fiber as the raw material, made through weaving technology.

2. Specification of PET Woven Geotextile

Breaking strength in MD(KN/m): 35, 50, 65, 80, 100, 120, 140, 160, 180, 200, 250;

Width: 1m – 6m.

3. Technical Data Sheet of PET Woven Geotextile

Item | Specification | ||||||||||

Material | Polyester | ||||||||||

MD(KN/m) | 35 | 50 | 65 | 80 | 100 | 120 | 140 | 160 | 180 | 200 | 250 |

CD(KN/m) | 35 | 50 | 65 | 80 | 100 | 120 | 140 | 160 | 180 | 200 | 250 |

Elongation at Break | MD=35; CD=30 | ||||||||||

Width Variation, % | ±0.1 | ||||||||||

CBR Mullen Burst Strength, KN | 2.0 | 4.0 | 6.0 | 8.0 | 10.5 | 13 | 15.5 | 18 | 20.5 | 23 | 28 |

Sieve Size O90(O95) mm | 0.07 ~ 0.50 | ||||||||||

Tearing Strength, KN | 0.5 | 00.8 | 1.1 | 1.3 | 1.5 | 1.7 | 1.9 | 2.1 | 2.3 | 2.5 | 3.0 |

Weight, g/m2 | 140 | 2200 | 260 | 320 | 390 | 450 | 530 | 600 | 680 | 760 | 950 |

Property of PET Woven Geotextile:

1) High strength, low deformation.

2) Durability: steady property, not easy to resolved, air slaked and can keep the original property long term.

3) Anti-erosion: anti-acid, anti-alkali, resists insects and mould.

4) Permeability: could control the sieve size to retain certain permeability.

Application of PET Woven Geotextile

It is widely used in river, coast, harbor, highway,railway, wharf, tunnel, bridge and other geotechnical engineering.

It could meet all kinds of geotechnical projects needs such as filtration, separation, reinforcement, protection and so on.

FAQ:

Questions and Answers:

Q: Can you accept sample order?

A: Yes, we accept samples with little and reasonable charge.

Q: What is your MOQ?

A: Normally, 5000 m2 per order.

Q: What is your delivery time? Can we short it in 7 days or less?

A: 7 days for sample, 20-25 days for mass production.

Q:How about your quality?

A: Try a small order, you will have your own judgment!

- Q:Are earthwork products resistant to chemical spills and contamination?

- Yes, earthwork products such as geosynthetics, geotextiles, and geomembranes are designed to be resistant to chemical spills and contamination. These materials are often used in environmental and containment applications where protection against chemicals, pollutants, and contaminants is crucial. They are engineered to have high chemical resistance and can effectively prevent the leakage and migration of hazardous substances.

- Q:Can earthwork products be used for creating walking paths and trails?

- Yes, earthwork products can be used for creating walking paths and trails. Earthwork products such as gravel, crushed stone, and soil can be used as surfacing materials for walking paths and trails, providing a stable and durable surface for pedestrians. These materials can help control erosion, improve drainage, and enhance the aesthetics of the path or trail. Additionally, earthwork products can be used to shape the terrain and create slopes or embankments along the path or trail to ensure proper grading and safety.

- Q:Are earthwork products suitable for constructing pedestrian bridges?

- Yes, earthwork products can be suitable for constructing pedestrian bridges. Earthwork materials such as soil, rocks, and gravel can be used as a foundation for building the bridge. Additionally, these materials can be used to create retaining walls, embankments, and approach ramps for the bridge, ensuring stability and accessibility for pedestrians.

- Q:What are the different types of geosynthetic drainage systems for sports fields?

- There are several types of geosynthetic drainage systems commonly used for sports fields. These include geocomposite drains, geonet drains, and geotextile drains. Geocomposite drains are made up of a combination of geotextile and a core material, typically a plastic drainage core, which allows for both water flow and filtration. Geonet drains consist of a three-dimensional mesh-like structure that provides a high flow capacity for water drainage. Geotextile drains, on the other hand, are made entirely of a permeable fabric material that allows water to pass through while preventing soil erosion. Each type of geosynthetic drainage system has its own benefits and is selected based on factors such as field type, soil conditions, and budget.

- Q:How do geosynthetic materials contribute to soil stabilization in agricultural applications?

- Geosynthetic materials contribute to soil stabilization in agricultural applications by providing reinforcement and erosion control. They are often used in the form of geotextiles, geogrids, or geocells to improve soil strength, prevent erosion, and enhance drainage. These materials help in stabilizing slopes, retaining walls, and embankments, reducing the risk of landslides or soil erosion. Moreover, geosynthetics can improve soil moisture retention, promote root growth, and protect plants from weed growth, ultimately enhancing agricultural productivity.

- Q:What are the benefits of using geocells in green infrastructure projects?

- There are several benefits of using geocells in green infrastructure projects. Firstly, geocells provide structural support and stability to vegetated surfaces, preventing soil erosion and promoting healthy plant growth. Secondly, they enhance stormwater management by improving infiltration rates and reducing runoff, thus mitigating the risk of flooding. Additionally, geocells help to create a more sustainable environment by using recycled materials in their construction and reducing the need for non-renewable resources. Lastly, these geosynthetic materials are cost-effective, easy to install, and require minimal maintenance, making them an efficient solution for green infrastructure projects.

- Q:I am now reading materials science and engineering, when the entrance examination, then you can report civil engineering professional?

- You are cross-professional, the teacher will not like, in the school should also pay attention to. If the election hook the direction of what, it is best not to report a good school. Re-test time will be affected. General school can still be considered.

- Q:Can geosynthetics be used for reinforcement in railway track construction?

- Yes, geosynthetics can be used for reinforcement in railway track construction. Geosynthetics, such as geotextiles or geogrids, can improve the stability and performance of railway tracks by providing additional strength and reducing track settlement. They are often used in trackbed stabilization, slope protection, and erosion control, enhancing the overall durability and longevity of the railway infrastructure.

- Q:Are earthwork products suitable for underground parking structures?

- Yes, earthwork products can be suitable for underground parking structures. The use of earthwork products, such as geotextiles, geogrids, and geocomposites, can provide effective solutions for soil stabilization, erosion control, and reinforcement in underground parking structures. These products help to improve the strength and durability of the ground, prevent soil erosion, and enhance the overall stability and performance of the structure.

- Q:What are the civil engineering materials?

- Inorganic cement, cement, concrete, mortar, steel, masonry, wood, synthetic polymer, waterproof material, decorative materials.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

High Strength Woven Geotextile for Road Construction Use

- Loading Port:

- Qingdao

- Payment Terms:

- TT or LC

- Min Order Qty:

- 20000 m²

- Supply Capability:

- 200000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords