High Quality OSB3 Board For Decoration Use

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m³

- Supply Capability:

- 10000 m³/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Brief Introduction:

OSB is manufactured from high quality coniferous from high quality coniferous wood. The veneer strands are precisely sliced from the side of clean, debarked wood logs so that the plane of the strand is parallel to the grain of the wood. These freshly cut strands are then dried, sorted and blended with a synthetic resin binder and defined portion of paraffin emulsion.

Because of its bending strength, OSB which is produced by us is the ultimate engineered wood product for timber framed constructions. The superior technical parameters of our OSB are the result of a carefully controlled process which retains the natural properties of wood. With its light and uniform wood surface it provides an attractive natural appearance and is used for a variety of decorative applications.

Pictures:

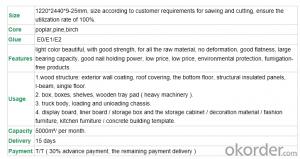

Description:

1)size:2000*125mm,2090*1180mm,2000*900mm

2)Thickness:

6-45mm(9.5mm,11.1mm,12mm,15mm,18mm) or as your request.

3)Core:pine and poplar

4)Glue:E1and E2

5)Density:350-400 kg/m³

Usage: Environmental protection Hollow particle board adopted high-quality imported logs as raw materials. It can be used for door cores, furniture, decorative, partition wall stuffing ,etc

OSB Board Feafures and Advantages:

Strong nail holding

♥ High bending strength

♥ Water-proof, moisture-proof

♥ Anti-corrosion protecting

♥ Strong shock resistance

♥ Low formaldenhyde emission

♥ Good heat and sound resistant

FAQ:

A: What's the main material of hollow chipboard?

B: Poplar and Pine

- Q:Particleboard industry is currently looking ahead

- and more attractive is the new technology without glue, it appears Will fundamentally change the particleboard industry.

- Q:So for the particleboard formaldehyde release of the situation how to deal with it?

- in fact, after the decoration of the room, such as Chlorophytum, Citrus grandis,

- Q:The product structure of the wood-based panel industry

- In addition, the orientation of particleboard, wood-plastic composite panels, waffles and crop straw board and other products of immature technology,

- Q:Make the raw material of the particleboard

- The dried shavings are then mixed with liquid gums and additives. Usually in the shavings of the surface area per square meter, sizing 8 to 12 grams

- Q:Particleboard production requires proper moisture content

- appropriate pressure time. The time is too short, the middle resin can not be fully cured, the finished product in the thickness of the elastic recovery increased,

- Q:What factors China's Particleboard industry development obstacles to

- particleboard industry developed rapidly, but the prevalence of small size, equipment and technology behind the problem, coupled with many companies do not pay attention to product quality,

- Q:Particleboard in the production process of environmental performance

- to be stored for some time after the observation room. If no spiky smell that particleboard release of formaldehyde less, the use will not affect human health

- Q:The Particleboard quality identification editor

- including North China, northwest, northeast plate moisture content is generally controlled at 6-8% is appropriate; the southern region,

- Q:What are the raw materials for making the particleboard?

- The former fat color is light, the curing temperature is low, all kinds of plant raw materials such as wheat straw, rice husk and so on have good glue effect, hot pressing temperature is 195 ~ 210 ℃.

- Q:What is the production process of particleboard

- the plate thickness deviation and the degree of material transfer between the shavings

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

High Quality OSB3 Board For Decoration Use

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m³

- Supply Capability:

- 10000 m³/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords