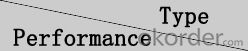

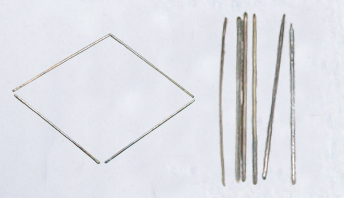

Heat-resistant stainless steel fibers melt pumping

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Steel Fiber Grade:

The grades of steel fiber should be suitably selected based on the temperature and atmosphere.

Physical, Mechanical and corrosion resistant properties of stainless steel fiber

| 304 | 310 | 330 | 446 | 430 |

Melting Point Range ℃ | 1400-1425 | 1400-1450 | 1400-1425 | 1425-1510 | 1425-1510 |

Elastic modulus at 870℃ | 12.66 | 12.66 | 13.71 | 9.84 | 8.44 |

Tensile strength at 870℃ | 127 | 155 | 197 | 54 | 48 |

Thermal expansion coefficient at | 20.16 | 18.58 | 17.64 | 13.14 | 13.68 |

Heat conductance at 500℃ | 21.5 | 18.7 | 21.6 | 24.4 | 26.3 |

Specific gravity at romm temperature, g/cm³ | 8.0 | 8.0 | 8.0 | 7.5 | 7.8 |

Loss of weight (%) after 1000 hours of circulating oxidization at 982℃(%) | 70(100h) | 13 | 18 | 4 | 70(100h) |

*Violent circulating state in air | 870 | 1035 | 1035 | 1175 | 870 |

982 | 1050 | 1150 | 1095 | 815 | |

Corrosion in H2S,Mil/yr | 200 | 100 | / | 100 | 200 |

Recommended max operating temperature when it is used in SO2℃ | 800 | 1050 | / | 1025 | 800 |

Corrosion in natural gas at 815℃ |

| 3 |

| 4 | 12 |

Corrosion in coking coal gas at 982℃ | 225 | 25 | 75 | 14 | 236 |

Nitrogenization in anhydrous ammonia at 525℃ | 80 | 55 | 20 | 175 | <304# |

Corrosion by CH2 at 454℃, Mil/yr | 4.8 | 2.3 |

| 8.7 | 21.9 |

Carbon pick-up of alloy % with solids carbonized at 982℃ for 24 hours and 40 times of circulations, % | 1.40 | 0.02 | 0.08 | 0.07 | 1.03 |

- Q:Is stainless steel wire resistant to UV rays?

- Yes, stainless steel wire is generally resistant to UV rays. Stainless steel is known for its corrosion resistance, and this extends to its ability to withstand the effects of UV rays. While prolonged exposure to direct sunlight may cause some discoloration or minor surface changes, stainless steel wire is unlikely to degrade or lose its structural integrity due to UV radiation. This makes it a suitable choice for outdoor applications, such as fencing, outdoor furniture, and architectural features, where it will be exposed to sunlight for extended periods. However, it's important to note that the specific grade and finish of stainless steel can affect its UV resistance, so it's always advisable to consult the manufacturer's recommendations for the best performance in outdoor environments.

- Q:Can stainless steel wire be used for springs in the telecommunications industry?

- Yes, stainless steel wire can be used for springs in the telecommunications industry. Stainless steel is a popular choice for springs due to its high strength, corrosion resistance, and durability. These properties make it suitable for various applications in telecommunications, including connectors, switches, and electrical contacts.

- Q:What are the different diameter options available for stainless steel wire?

- Stainless steel wire is available in a wide range of diameter options to suit various applications. The diameter options typically vary from as small as 0.001 inches (0.0254 mm) to as large as 0.375 inches (9.525 mm) or even more. The specific diameter options available for stainless steel wire depend on the specific grade and type of stainless steel being used. Commonly, stainless steel wire is available in diameters ranging from 0.001 inches (0.0254 mm) to 0.625 inches (15.875 mm). However, it is important to note that certain specialty grades or custom orders may offer even smaller or larger diameter options. The choice of diameter depends on the intended application of the stainless steel wire. Thinner diameter wires are often used in applications where flexibility and ease of handling are important, such as in the manufacturing of medical devices, jewelry, or fine mesh screens. Thicker diameter wires, on the other hand, are typically used in applications that require high strength and durability, such as in structural components, springs, or heavy-duty fencing. It is recommended to consult with a stainless steel wire supplier or manufacturer to determine the specific diameter options available for a particular grade or type of stainless steel wire. They can provide guidance based on the intended application and requirements, ensuring that the chosen diameter will meet the needs of the project.

- Q:What are the different types of stainless steel wire rope coatings available?

- There are several different types of stainless steel wire rope coatings available, each with its own unique properties and advantages. Some of the most common coatings include: 1. Vinyl Coating: This is a popular choice for stainless steel wire ropes as it provides excellent resistance against corrosion, abrasion, and weathering. It is also available in various colors, which can help with identification and organization. 2. Nylon Coating: Nylon coating offers similar benefits to vinyl coating but with added strength and durability. It provides enhanced resistance against abrasion and is often used in applications that require additional protection against wear and tear. 3. Polyethylene Coating: This coating is known for its exceptional resistance to chemicals, moisture, and UV radiation. It is commonly used in marine environments or areas with high levels of exposure to harsh weather conditions. 4. Epoxy Coating: Epoxy coatings provide superior protection against corrosion and can withstand extreme temperatures. They are often used in industrial settings where wires may come into contact with chemicals, oils, or solvents. 5. Galvanized Coating: Although not a stainless steel wire rope coating per se, galvanization involves applying a layer of zinc to the wire rope's surface to protect it from rust and corrosion. This coating is commonly used in outdoor and marine applications. When choosing a stainless steel wire rope coating, it is essential to consider the specific requirements of your application. Factors such as environmental conditions, exposure to chemicals or moisture, and desired durability will help determine the most suitable coating option for your needs.

- Q:Can stainless steel wire be used for making wire bird cages?

- Certainly! Wire bird cages can indeed be made using stainless steel wire. The reason why stainless steel is a favored option for crafting bird cages lies in its remarkable attributes: durability, strength, and resistance to corrosion. This material ensures a secure and reliable environment for birds, allowing them to be visible and ventilated. Moreover, stainless steel wire is non-toxic, ensuring the safety of the birds even if they happen to nibble on it. Furthermore, its easy maintenance and cleaning properties make stainless steel an ideal choice for bird cages.

- Q:What are the different types of stainless steel wire screens for windows?

- There are several different types of stainless steel wire screens for windows, including plain weave screens, twill weave screens, and Dutch weave screens. Each type has its own unique characteristics and benefits, such as different levels of airflow and visibility, as well as varying levels of durability and resistance to corrosion. The choice of which type to use depends on specific needs and preferences.

- Q:Are there any safety concerns when handling stainless steel wire?

- Yes, there are some safety concerns when handling stainless steel wire. Firstly, stainless steel wire can have sharp edges that can easily cause cuts or puncture wounds if not handled with care. It is important to wear protective gloves when working with stainless steel wire to prevent any injuries. Secondly, stainless steel wire can be quite strong and can cause strain or muscle fatigue if handled incorrectly. It is important to use proper lifting techniques and avoid overexertion when working with heavy or large quantities of stainless steel wire. Additionally, stainless steel wire can become very hot when heated or during certain manufacturing processes. It is important to handle it with appropriate heat-resistant gloves to avoid burns or other thermal injuries. Furthermore, stainless steel wire may contain small amounts of nickel, which can cause allergic reactions in some individuals. If you have known allergies or sensitivities to nickel, it is important to take necessary precautions such as wearing gloves or using barriers to prevent direct contact with the wire. Lastly, when working with stainless steel wire, there is a risk of eye injuries due to flying particles or sparks. It is important to wear safety glasses or goggles to protect your eyes from any potential hazards. Overall, while stainless steel wire is generally safe to handle, it is important to be aware of these safety concerns and take necessary precautions to minimize the risk of injuries or accidents.

- Q:Can stainless steel wire be used for fishing tackle?

- Yes, stainless steel wire can be used for fishing tackle. Stainless steel wire is known for its strength, durability, and resistance to corrosion, making it a popular choice for various fishing applications. It is commonly used to make leaders, which are the sections of line that connect the main fishing line to the hook or lure. Stainless steel wire leaders are particularly useful when targeting predatory fish species with sharp teeth or abrasive mouths, as they provide a tough and reliable barrier against bite-offs. Additionally, stainless steel wire can also be used to make fishing rigs, such as spreader bars or wire traces, which are used in certain fishing techniques. However, it is important to note that the specific type and thickness of stainless steel wire used should be suitable for the target fish species and fishing conditions to ensure optimal performance and safety.

- Q:Can stainless steel wire be used for wire shelving?

- Wire shelving can definitely make use of stainless steel wire. Stainless steel wire is a material that boasts great durability and resistance, making it a fantastic option for wire shelving. With its rust-resistant properties, this material guarantees the longevity and hassle-free use of the shelving. Moreover, stainless steel wire is known for its remarkable strength and capacity to bear heavy loads without bending or sagging. In addition to all these advantages, stainless steel is also quite easy to clean and maintain, ensuring hygiene and making it a suitable choice for different settings, including commercial, industrial, and residential spaces.

- Q:What are the different wire coil sizes available for stainless steel wire?

- Stainless steel wire offers a range of wire coil sizes to cater to diverse application needs and specifications. The diameter of the commonly used stainless steel wire coils typically varies from 0.020 inches (0.5 mm) to 0.625 inches (15.9 mm). For specific industrial purposes, larger coil sizes, like 1 inch (25.4 mm) or even bigger, can also be obtained. When deciding on the appropriate wire coil size, factors like intended usage, desired strength, and compatibility with machinery or equipment must be taken into account.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Heat-resistant stainless steel fibers melt pumping

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords