HDPE Uniaxial Geogrid with High Tensile Strength Manufacturer

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 g/m²

- Supply Capability:

- 100000 g/m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

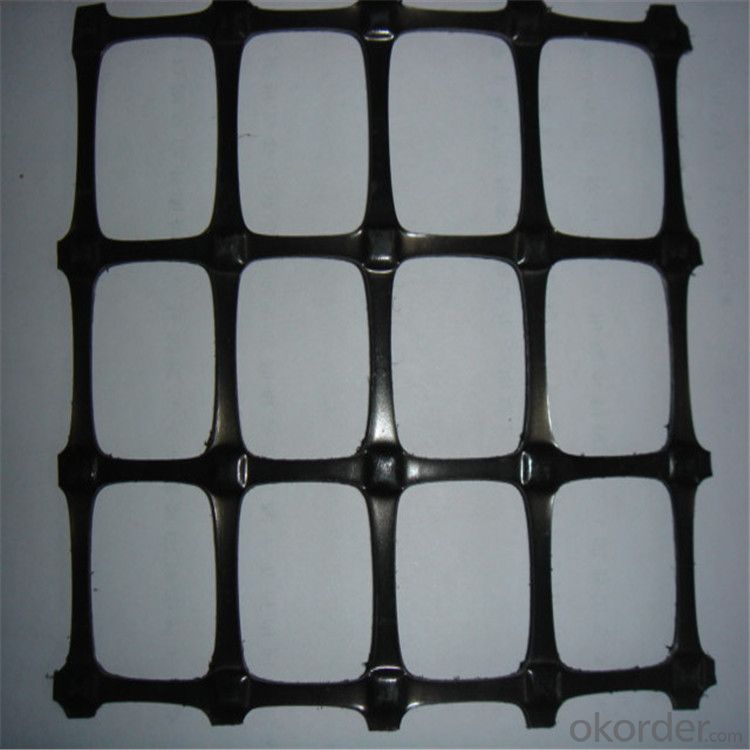

Product Specification---HDPE UniaxialGeogrid

Introduction:

HDPE Uniaxial geogrid, made of high molecular polymer, is extruded into sheet and then punched

into regular mesh pattern, and finally stretched in the longitudinal direction.

Features:

With high tensile strength and tensile modulus

Application:

Mainly applied in highway, railway, slope protecting projects, retaining wall, dam etc.

1) strengthen land loading capacity

and extend its service life.

2) convenient to construct ;

reducing area , project cost and maintenance cost.

Tensile Strength ≧(Kn/m) | MD | 15 | 20 | 25 | 30 | 35 | 40 | 45 | 50 | |

TD | 15 | 20 | 25 | 30 | 35 | 40 | 45 | 50 | ||

Nominal Elongation ≦(%) | MD | 15 | ||||||||

TD | 13 | |||||||||

Tensile Strength at 2% Strain ≧(Kn/m) | MD | 5 | 7 | 9 | 10.5 | 12 | 14 | 16 | 17.5 | |

TD | 5 | 7 | 9 | 10.5 | 12 | 14 | 16 | 17.5 | ||

Tensile Strength at 5% Strain ≧(Kn/m) | MD | 7 | 14 | 17 | 21 | 24 | 28 | 32 | 35 | |

TD | 7 | 14 | 17 | 21 | 24 | 28 | 32 | 35 | ||

Junction Efficiency (%) | 93 | |||||||||

Width ≦(m) | 6 | |||||||||

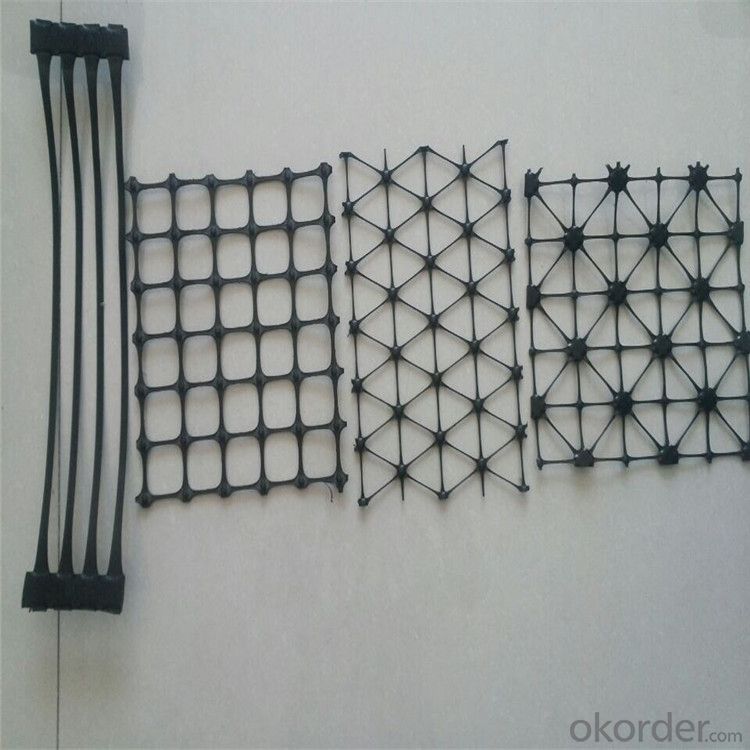

Images of HDPE Biaxial Geogrid

- Q:How do geogrids enhance the stability of mechanically stabilized earth walls?

- Geogrids enhance the stability of mechanically stabilized earth walls by providing reinforcement and increasing the overall strength of the structure. They are typically made of high-strength materials like polyester or polypropylene, and are placed within the soil layers of the wall. The geogrids interact with the soil, creating a tensile force that redistributes the loads and prevents excessive movement or sliding of the wall. This reinforcement improves the overall stability and durability of the mechanically stabilized earth wall.

- Q:And specification.. Thank you for answering me

- In order to achieve an asymmetric competitive advantage, now the problem of engineering design is really big, institutional problems

- Q:How much investment is needed for the grid cloth on the production site

- The mesh cloth is made of alkali or alkali free glass fiber yarn, which is coated with alkali resistant polymer emulsion. Mesh cloth series products: alkali resistant GRC fiberglass mesh cloth, alkali resistant wall mesh and stone mesh cloth, marble back mesh cloth.

- Q:Can geogrids be used in subgrade improvement?

- Yes, geogrids can be used in subgrade improvement. Geogrids are often used in civil engineering projects to reinforce and stabilize weak soils in the subgrade. They can help to distribute loads more evenly, increase bearing capacity, and reduce settlement. Additionally, geogrids can improve the overall performance and longevity of the subgrade, making them a valuable tool in subgrade improvement projects.

- Q:How do geogrids help in reducing construction waste?

- Geogrids help in reducing construction waste by providing reinforcement and stabilization to soil, reducing the need for excessive excavation and material usage.

- Q:How do geogrids improve the performance of geosynthetic-reinforced retaining walls?

- Geogrids improve the performance of geosynthetic-reinforced retaining walls by providing tensile reinforcement to the soil, increasing its overall strength and stability. They help distribute the lateral forces exerted on the wall, preventing potential wall failure or deformations. Additionally, geogrids increase the bearing capacity of the soil, allowing for the construction of taller and steeper walls.

- Q:Can geogrids be used in mining tailings containment?

- Yes, geogrids can be used in mining tailings containment. Geogrids are often used in mining operations to reinforce and stabilize containment structures, such as tailings dams, due to their high tensile strength and ability to distribute loads. They help prevent slope failures and erosion, improving the overall stability and longevity of tailings containment systems.

- Q:What is the recommended spacing between geogrid layers?

- The recommended spacing between geogrid layers can vary depending on the specific project and soil conditions. However, in general, a spacing of about 2 to 3 feet (0.6 to 0.9 meters) is often recommended to achieve optimal reinforcement and stability.

- Q:Can geogrids be used in gabion wall construction?

- Yes, geogrids can be used in gabion wall construction. Geogrids are commonly used as reinforcement materials in gabion walls to enhance their stability and strength. They help distribute the load from the wall evenly, preventing bulging or deformation. Additionally, geogrids can also improve the overall performance of gabion walls by reducing settlement and increasing the resistance to external forces such as earthquakes or water pressure.

- Q:What kind of circumstances need to shop geogrid

- In the treatment of bad foundation, or the transformation of the old road, geogrid can quickly improve the bearing capacity of the foundation, speed up the progress of construction; control of soft ground settlement development, shorten the construction period, so that the early use of the road.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

HDPE Uniaxial Geogrid with High Tensile Strength Manufacturer

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 g/m²

- Supply Capability:

- 100000 g/m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords