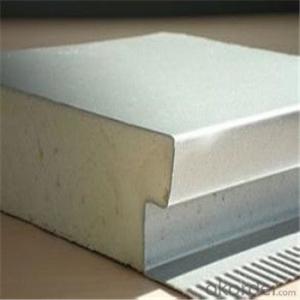

Good quality corrugated EPS sandwich panel for prefab building

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 3000 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Packaging & Delivery

| Packaging Detail: | corrugated EPS sandwich panel 1. Naked packing in 20' or 40' container 2. Steel pallet with belt in 40' container |

| Delivery Detail: | 15-20 days after receipt of down payment for wall panel |

Specifications

corrugated EPS sandwich panel

1)sound & hot insulation

2)fire&water proof

3)thickness: 25-100mm

4)USD13-28/m2

Packaging & Delivery

| Packaging Detail: | corrugated EPS sandwich panel 1. Naked packing in 20' or 40' container 2. Steel pallet with belt in 40' container |

| Delivery Detail: | 15-20 days after receipt of down payment for wall panel |

Specifications

corrugated EPS sandwich panel

1)sound & hot insulation

2)fire&water proof

3)thickness: 25-100mm

4)USD13-28/m2

Corrugated EPS sandwich panel for prefab building

Product Description

Corrugated EPS sandwich panel is composed of two layers of pre painted steel sheets with the hard forms of polyurethane as core, which features fireproof materials. It is suitable for the various roofs and walls referring to the large-size factory buildings, storages, exhibition halls, gymnasiums, freezing stores, purification workshops etc, which features temperature-keeping, heat insulation, weight-bearing, weatherproof with the rich color and good appearance.

Specification: | |

Surface Texture and Appearance | Small wave, Flat, Big rib |

Thickness of steel plate | 0.35-0.6mm |

Heat Insulating Material | EPS(polystyrene) |

Thermal conductivity | 0.044w/m.k |

Unit Weight of Core Material | 7-20KG/m3 |

Thickness of Core Material | 40mm, 50mm, 75mm, 100mm,(min thickness for roof: 30mm) |

Effect Width | 950mm, 1150mm |

Color | White grey, Sliver, Sea Blue, Red, etc |

Recommended Coating | PE, PVDF, HDP |

Recommended Plating | Hot-dip galvanized, Al-Zn coated |

Features | 1.Fire resistant; 2.Heat Insulating; 3.Light Weight |

Corrugated EPS sandwich panel application

* Steel structure warehouse

* Temporary office & accommodation

* Commercial prefab building for poultry

Packaging & Shipping

In order to save the space & load the max quantity, it is normally without packing. But steel plate pallet packing for corrugated EPS sandwich panel is also workable.

- Q:Color steel sandwich panels and color steel plate What is the difference

- Galvanized steel pipe is divided into cold galvanized steel pipe, hot galvanized steel pipe, cold galvanized steel pipe has been banned, which is also the country to promote the temporary use

- Q:Reinforced concrete and metal sandwich board how much difference

- JGJ130 has regulations. Not more than 0.4L, and not more than 500mm

- Q:What is the weight per unit area of 100 thick rock wool sandwich panels?

- First, the electricity management: ⒈ temporary electricity must be "" construction site temporary electricity safety technical specifications "JGJ46-88" compilation of electricity construction organization design and development of safe electricity technical measures and electrical fire protection measures. ⒉ temporary electricity engineering drawings must be drawn solely by the electrical engineering and technical personnel, after the approval of the technical person as a temporary basis for construction. ⒊ temporary electricity construction organization design content and steps: ⑴ site exploration, to determine the power line into the total distribution box (cabinet), the distribution of electrical box location and line direction. ⑵ load calculation, select the wire cross-section and electrical type, specifications. ⑶ draw electrical plan, elevation and wiring system diagram.

- Q:Are sandwich panels suitable for food kiosks?

- Yes, sandwich panels are suitable for food kiosks. Sandwich panels are commonly used in the construction of food kiosks due to their durability, insulation properties, and ease of installation. They provide a hygienic and easy-to-maintain surface, making them ideal for food-related businesses. Additionally, sandwich panels offer flexibility in design and can be customized to meet specific requirements, making them a popular choice for food kiosks.

- Q:What is the quota of the demolition of the color steel plate?

- Answer: safety production laws and regulations, including safety in production (BE) A

- Q:Color steel tile and Caigang sandwich board What is the difference between the use of what is the difference

- That depends on the savvy! Way more than difficult!

- Q:Color steel sandwich panel price table color steel sandwich board how much money a square meter

- Height of 24m below the double scaffold can be flexible connection, but must be used to withstand the tension and pressure structure.

- Q:Are sandwich panels suitable for automotive showrooms?

- Sandwich panels are an ideal option for automotive showrooms. Comprised of two outer layers or skins with a lightweight core material in between, these panels offer exceptional strength and insulation qualities. They are versatile and can be utilized in various ways, including building facades, partitions, and interior walls. Within automotive showrooms, sandwich panels can be employed to construct walls, ceilings, and even floors. They bring numerous advantages that make them perfect for this setting. Firstly, they provide excellent insulation, ensuring a comfortable temperature inside the showroom regardless of external weather conditions. This is crucial for creating a pleasant atmosphere for both customers and staff. Moreover, sandwich panels are lightweight and easy to install, allowing for efficient and fast construction. This is advantageous for automotive showrooms, as they often face tight deadlines and need to become operational as soon as possible. The panels can be easily cut and shaped to fit specific design requirements, offering flexibility in creating unique and appealing showroom layouts. Additionally, sandwich panels possess excellent noise reduction qualities, guaranteeing a quieter environment within the showroom. This is significant in providing a comfortable ambiance for customers and enabling them to focus on the showcased vehicles. Furthermore, sandwich panels are durable and require minimal maintenance. They are resilient against corrosion, moisture, and fire, providing a long-lasting and safe solution for automotive showrooms. Additionally, the outer layers of the panels can be customized with various finishes and colors, allowing for the incorporation of branding and aesthetic preferences into the showroom design. In conclusion, sandwich panels are a suitable choice for automotive showrooms due to their insulation properties, ease of installation, noise reduction capabilities, durability, and customization options. They offer a cost-effective and efficient solution for creating a functional and visually appealing environment to showcase vehicles.

- Q:What is the difference between rock wool sandwich panels, EPS sandwich panels and polyurethane sandwich panels?

- Can do the insulation that is the foam board, the so-called insulation of the extruded board with high Ji floating reed kill the devil ghost Tong Kankan Kun resistance, low linearity, low expansion characteristics of the structure of the closed-cell rate reached 99% Above, the formation of vacuum layer, to avoid air flow cooling, to ensure its long-term stability and stability, relative to the foam polyurethane 80% of the closed-hole rate, the leading advantage is self-evident

- Q:What are the different types and uses of clean color steel plates?

- Color steel sandwich panels: 1. Corrugated sandwich board may be in the fixed time when the nail is too tight lead to corrugated subsidence, the formation of small puddles, it will leak, the solution with mildew copper phosphate repair. 2. Flat sandwich plate may be due to the possibility of two plates of the gap between the edge of the gap is not enough height, the general rain is no problem, the amount of rain on the big leak, the solution is to increase the height of the edge fold (the cost of repair each gap about 15 yuan about). Also do not understand can ask questions.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Good quality corrugated EPS sandwich panel for prefab building

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 3000 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords