Glass Wool Insulation Batts

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1000 roll

- Supply Capability:

- 1000000 roll/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Glass wool Blanket with Facing for thermal Insulation

1.Structure of Glass wool Blanket with Facing for thermal Insulation:

Glass wool with Facing is an industrial product made by spinning glass into a fibrous material that can be packed in mats and Blankets. This product is used as insulation and in other applications, like for air filters. Glass wool is 100% recyclable. It is manufactured from sand and recycled glass(up tp 80% cullet) and offers a very positive environmental balance sheet. It protects the environment, from the beginning to the end of its life cycle and gives more comfort and savings to the occupants of the buildings it insulates.

Glass wool raw materials The basic raw materials for fiberglass products are a variety of natural minerals and manufactured chemicals. The major ingredients are silica sand, limestone, and soda ash. Other ingredients may include calcined alumina, borax, feldspar, nepheline syenite, magnesite, and kaolin clay, among others. Silica sand is used as the glass former, and soda ash and limestone help primarily to lower the melting temperature. Other ingredients are used to improve certain properties, such as borax for chemical resistance. Waste glass, also called cullet, is also used as a raw material. The raw materials must be carefully weighed in exact quantities and thoroughly mixed together (called batching) before being melted into glass.

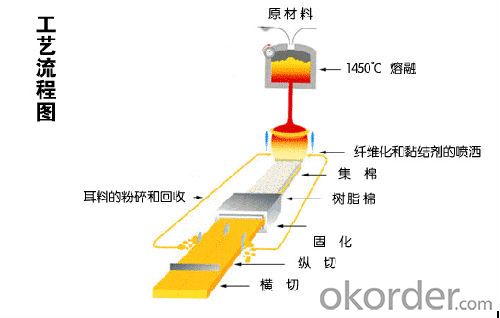

The Manufacturing Process

Melting / Forming into fibers /Continuous-filament process/Staple-fiber process/ Chopped fiber/ Glass wool / Protective coatings /Forming into shapes

2.Main Features of Glass wool Blanket with Facing for thermal Insulation:

The glass wool Blanket with Facing is applied for large laying area. In the field of insulation materials, we are mainly specializing in Glass wool products, including Blankets, Blankets and pipes. The advantage of this material is numerous: noncombustible, nontoxic, and resistant to corrosion. It has low weight, low thermal conductivity, stable chemical property, low moisture rate and good hydrophobicity. These products have been widely used in heat preservation, thermal insulation and sound absorption in construction, chemical industry, electronic industry, electric power, metallurgy, energy industry, and communication. High density panels laminated with facing can be used for Air-conditioning duct system.

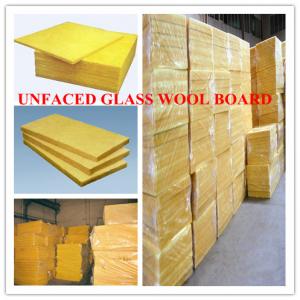

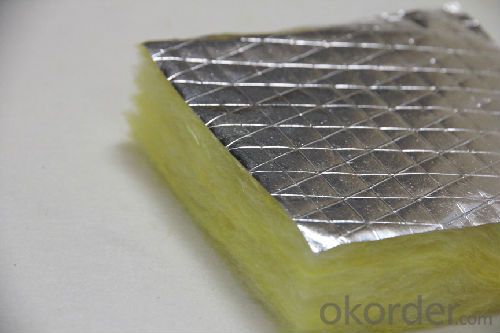

3. Glass wool Blanket with Facing for thermal Insulation Images

4. Glass wool Blanket with Facing for thermal Insulation Specification

The glass wool Blanket is applied for large laying area. Besides the character of thermal insurance, it also has the performances of shock absorption and acoustical isolation, especially for middle or low frequency sound. It also can cancel the noise and improve working environment.

The glass wool Blanket with Facing surface has good capability of heat radiation protection.

Technical Data

Item | Unit | Index |

Density | Kg/m3 | 12-96 |

Thickness | mm | 25-150 |

Width | mm | 600-1200 |

Length | mm | 1200-3000 |

Both unfaced and faced felts can be provided.

5.FAQ

We have organized several common questions for our clients,may help you sincerely:

① Where you used this?

These products have been widely used in heat preservation, thermal insulation and sound absorption in construction, chemical industry, electronic industry, electric power, metallurgy, energy industry, and communication. High density panels laminated with facing can be used for Air-conditioning duct system.

②How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

③How you control the quality?

During the production of fiberglass insulation, material is sampled at a number of locations in the process to maintain quality.

- Q:How is the prospects for rock wool board and glass wool board?

- It is good.Some countries control the use of extruded polystyrene board.Moreover, no new and better energy-saving materials emerge.Therefore, these two materials will be more widely used.

- Q:If the glass wool is used for thermal insulation outside seamless steel tube, should the pipe be rust-proof and sprayed paint?

- Definitely need. Insulating layer can be used as antii-corrosion coating! Do according to the design and painting specifications!

- Q:What's the difference between glass?wool?board and rock wool board ?

- In fact, it is very simple. Glass wool is processed from glass (silicon?dioxide) , while rock wool is made from basalt or diabase through high temperature refining equipment, which are two completely different products. Hope it is helpful.

- Q:What is the function of glass wool foil?

- Glass is made by melting such raw materials as quartz sand, limestone, dolomite and other natural ore with some chemical materials like pure alkali and sodium borate. In the molten state, the glass is thrown into fine fibers in the shape of floc by the with external force. These fibres vertically interwine and show many small gaps. These gaps can be regarded as air void. Thus, glass wool can be regarded as porous materials and it is of good insulation and sound absorption performance.

- Q:What are the standards of glass wool board?

- The thickness of glass wool board are 0.7 mm and 0.5m m, and it will soon enter the thinner (eg 0.4mm) thickness process. Basically, a TFT- LCD panel needs two glass substrates, they are used for bottom glass substrate and the base plate of color filter. Generally, the supply proportion of liquid crystal plate assembling factory and processing factory of the color filter glass substrate by glass substrate manufacturing suppliers is about 1:1.1 to 1:1.3.

- Q:Which has better effect of sound absorption, glass wool or rock wool?

- Almost the same, no significant difference. You can send me message if you have some trouble.

- Q:Whether the combustion performance of glass wool blanket can reach A grade

- Yes, it is A grade

- Q:How about the quoted price of asphalt glass wool felt?

- The prices of asphalt glass wool felt have something to do with the quality of products and brands. Currently, most of this kind of products cost $ 2 to 3. I suggest you go to the local market to know more.

- Q:The glass wool board of Kunnai Building Materials Corporation have different densities. Are there any differences?

- Sound insualtion effect varies with density and thickness of the boards. The boards with higher density and which is also thicker have better sound insulation.

- Q:How about the thermal insulation performance of glass wool?

- It is good. The heat conductivity coefficient of glass wool is 0.043, the heat preservation property of which is less than that of rock wool of 0.041. The thermal insulation performance and fireproofness are better than that of glass wool, but the price of it is also higher than that of glass wool. But the site construction operation of rock wool is not as good as that of glass wool. If it is a direct composite of production line, then it has nothing to worry about.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Glass Wool Insulation Batts

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1000 roll

- Supply Capability:

- 1000000 roll/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords