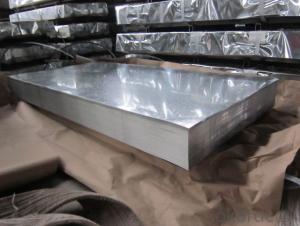

Galvanized Steel Sheet Export on OKorder.com

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 m.t

- Supply Capability:

- 300 m.t/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Galvanized Steel Sheet raw steel material from Big Mill with reliable quality.

Construction, packaging, railway vehicles, agricultural machinery and daily life.

Oiled/dry, Skin-pass/Nonskin-pass, Regular/Minimize/Zero Spangle

Application: with excellent cold bending molded manufacturablity, good decoration effect, strong anti-corrosion ability, galvanized steel coils and sheets are also pollution-free and easily recycled. Accordingly, they can be used as final products and basic plates of color coated steel coils and widely applied in construction, home appliances, decoration, ect.

CORRUGATED GALVANIZED STEEL SHEETS

Base sheet : galvanized steel sheet, pre painted galvanized steel sheet

Zinc:40G-275G

Thickness:0.12mm-3.2mm

Width:600mm-1500mm

Length:1000mm-11800mm or as request

Package:Standard seaworthy export packing: 3 layers of packing, inside is

kraft paper,water plastic film is in the middle and outside GI steel

sheet to be covered by steel strips with lock.

After the chemical reaction between aluminum and oxygen in the air, A layer of strong and dense oxide film will be generated. This layer of aluminum oxide film preservation became "coat", the internal aluminum is difficult for them to oxygen in the air to oxidation, so aluminum is placed in the atmosphere a year, which is less than the depth of corrosion of thousands of hours one millimeter. If the same time into the aluminum and steel containing 3% of sodium chloride and 1% of the hydrogen chloride in the container, the corrosion test of 70 hours, the average weight loss of steel per square centimeter 11.07 mg in weight loss of aluminum average of 0.675 milligrams per square centimeter, which proves the corrosion resistance of aluminum is generally much higher than the steel. However, the natural oxide film of aluminum, there are still shortcomings thin and soft, corrosion is not very strong, so that the service life of corrugated sheet aluminum untreated generally only about 20 years. If aluminum by chemical oxidation (i.e., at a certain temperature of the aluminum oxide surface cleaning and liquid oxygen in a chemical reaction) or electrochemical oxidation (i.e. the aluminum into the electrolyte, in the role of the applied current and oxygen ions the method of a direct reaction of water with aluminum surface cleaning) are processed, on the surface of the aluminum layer will generate 0.025 to about 0.05 millimeters thick and hard and even more some of the oxide film, so as to further improve the corrosion resistance of aluminum performance. After aluminum corrugated sheets thus treated, the service life of up to 60 years. Aluminum corrugated sheets can also be a variety of bright colors, it is possible to make the building more beautiful.

- Q:Are steel sheets suitable for roofing systems?

- Yes, steel sheets are suitable for roofing systems. They are durable, long-lasting, and resistant to various weather conditions, making them an ideal choice for protecting buildings from the elements. Additionally, steel sheets are lightweight, easy to install, and require minimal maintenance, making them a cost-effective option for roofing systems.

- Q:How do steel sheets perform in terms of wear resistance?

- Steel sheets generally perform very well in terms of wear resistance. Steel is known for its strength and durability, and steel sheets are no exception. They are able to withstand heavy loads, abrasion, and impact, making them suitable for a wide range of applications where wear resistance is crucial. Additionally, steel sheets can be further enhanced with surface treatments or coatings to improve their wear resistance even more. Overall, steel sheets are a popular choice for industries that require materials capable of withstanding wear and tear over extended periods of time.

- Q:What are the different methods of protecting steel sheets from scratches?

- There are several methods of protecting steel sheets from scratches. One common method is applying a protective coating or paint on the surface of the steel sheet. This coating acts as a barrier and prevents scratches from occurring. Another method is using a temporary protective film or tape on the steel sheet. This film or tape can be easily applied and removed, providing a temporary safeguard against scratches. Additionally, using padded or protective packaging during transportation or storage can help prevent scratches. Implementing proper handling and storage procedures, such as using non-abrasive materials and avoiding stacking or sliding steel sheets, can also minimize the risk of scratches.

- Q:What is the impact resistance of steel sheets?

- The impact resistance of steel sheets is generally high due to the inherent strength and toughness of steel. It can withstand and absorb significant amounts of force or impact without deforming or breaking, making it suitable for various applications that require durability and protection against impacts.

- Q:Can steel sheets be used for architectural purposes?

- Yes, steel sheets can be used for architectural purposes. They are often utilized in construction projects for their durability, strength, and versatility. Steel sheets can be used for roofing, cladding, facades, and structural applications, providing a modern and sleek aesthetic while also offering structural integrity and resistance to weather conditions.

- Q:How is the quality of steel sheets determined?

- The quality of steel sheets is determined by various factors such as the composition of the steel, its mechanical properties, surface finish, and dimensional accuracy. It undergoes rigorous testing for strength, ductility, hardness, and resistance to corrosion. Additionally, the manufacturing process, including the selection of raw materials and adherence to industry standards, plays a significant role in determining the quality of steel sheets.

- Q:What is the difference between a brushed and etched steel sheet?

- A brushed steel sheet and an etched steel sheet are both types of metal sheets that have undergone different surface treatments, resulting in distinct appearances and characteristics. A brushed steel sheet is created by brushing the surface of the steel with an abrasive material, usually a wire brush or sandpaper. This process creates a textured pattern of fine lines or scratches on the surface of the steel. The purpose of brushing is primarily to enhance the aesthetic appeal of the steel sheet, giving it a satin-like finish. Brushed steel is often used in architectural and design applications where a sleek and contemporary look is desired. It is also commonly used in kitchen appliances and automotive parts due to its resistance to fingerprints and scratches. On the other hand, an etched steel sheet is produced by a chemical or acid etching process. This involves applying an acid-resistant material, such as a resist or a stencil, onto the steel surface and then exposing it to an acid solution. The acid eats away at the exposed parts of the steel, creating a pattern or design. Etching is used to achieve intricate and detailed designs on steel sheets, making it popular in industries such as signage, jewelry, and art. The etched patterns can range from simple geometric shapes to elaborate images or text. In summary, the main difference between a brushed and etched steel sheet lies in the method used to achieve their respective surface textures. Brushing results in a consistent pattern of fine lines, creating a satin-like finish for aesthetic purposes. Etching, on the other hand, involves a chemical process that creates detailed and intricate designs on the steel surface.

- Q:Are steel sheets suitable for HVAC systems?

- Certainly, HVAC systems can make use of steel sheets. Steel sheets are extensively employed in HVAC systems owing to their durability, strength, and corrosion resistance. They contribute to the structural integrity of the system and can endure high temperatures and pressure. Furthermore, steel sheets can be conveniently fabricated and tailored to meet specific requirements of the HVAC system. In addition, they are cost-efficient and have a prolonged lifespan, making them a favored option for components like ductwork, ventilation systems, and air handling units within HVAC systems.

- Q:Are steel sheets resistant to termite infestation?

- No, steel sheets are not resistant to termite infestation. Termites are known to feed on wood and other cellulose-based materials, but they can also cause damage to steel structures indirectly. Termites can burrow through other materials, such as concrete or insulation, to reach the wooden components of a structure. Therefore, while steel sheets themselves may not be directly affected by termites, the overall integrity of a building or structure can still be compromised if termites gain access to the wooden components. It is important to take preventive measures and regularly inspect and treat any vulnerable areas to protect against termite infestation, regardless of the presence of steel sheets.

- Q:Do the steel sheets come in different finishes?

- Indeed, steel sheets are available in various finishes. Among the most frequently used finishes for steel sheets are brushed, polished, matte, satin, and textured. These finishes are attained through diverse methods, including grinding, sanding, or applying chemical treatments. The preferred finish is contingent upon the desired visual appeal, functionality, and intended purpose of the steel sheet. Diverse finishes can offer distinct degrees of luster, sleekness, or texture, thereby enabling customization and adaptability across a range of applications, including architectural, automotive, and industrial sectors.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Galvanized Steel Sheet Export on OKorder.com

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 m.t

- Supply Capability:

- 300 m.t/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords