Galvanized Steel Sheet Coil from China High Quality

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Hot-dip Zinc Coating Steel Building Roof Walls

1.Structure of Hot-Dip Galvanized Steel Sheet Description:

Hot-dip galvanized steel coils are available with a pure zinc coating through the hot-dip galvanizing process. It offers the economy, strength and formability of steel combined with the corrosion resistance of zinc. The hot-dip process is the process by which steel gets coated in layers of zinc to protect against rust. It is especially useful for countless outdoor and industrial applications. Production of cold formed corrugated sheets and profiles for roofing, cladding, decking, tiles, sandwich walls, rainwater protective systems, air conditioning duct as well as electrical appliances and engineering.

2.Main Features of the Hot-Dip Galvanized Steel Sheet:

• Excellent process capability

• Smooth and flat surface

• Workability, durability

• Excellent anticorrosive property

• High strength

• Good formability

• Good visual effect

3.Hot-Dip Galvanized Steel Sheet Images:

4.Hot-Dip Galvanized Steel Sheet Specification:

Standard: ASTM, JIS,EN

Grade: CS, DX51D+Z,SGCC, SS 230~550,S220GD+Z~S550GD+Z, SGC340~SGC570

Thickness: 0.1mm~5mm

Width: max 2000mm

Coil weight:3-12 MT

Coil ID:508/610mm

Surface structure: zero spangle, regular spangle or minimum spangle

Surface treatment: Chromate treatment, Oiled/dry, skinpassed/non-skinpassed

Packing: Standard seaworthy export package

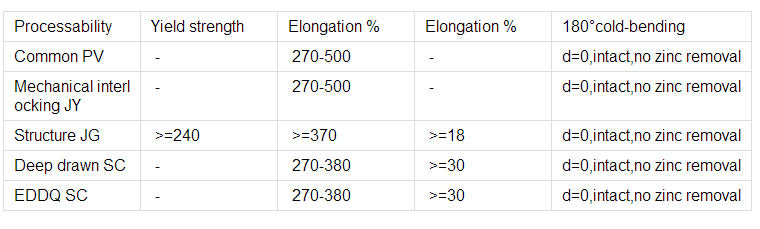

Technology test results:

5.FAQ of Hot-Dip Galvanized Steel Sheet:

We have organized several common questions for our clients,may help you sincerely:

1.How about your company?

A world class manufacturer & supplier of castings forging in carbon steel and alloy steel,is one of the large-scale professional investment casting production bases in China,consisting of both casting foundry forging and machining factory. Annually more than 8000 tons Precision casting and forging parts are exported to markets in Europe,America and Japan. OEM casting and forging service available according to customer’s requirements.

2.How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

3. How long can we receive the product after purchase?

Usually within thirty working days after receiving buyer’s advance payment or LC. We will arrange the factory manufacturing as soon as possible. The cargo readiness usually takes 15-30 days, but the shipment will depend on the vessel situation.

The occurrence of anode effects is because as the electrolysis process, oxygen-ion electrolyte gradually reduced, when a certain degree, there is precipitation of fluorine and carbon generate carbon anode effects fluoride, carbon fluoride in the decomposition time and fine carbon particles deposited on the carbon particles attached to the surface of the anode, electrolyte and anode to prevent contact of the electrolyte cannot properly wet the anode, like water cannot wet oiled surface as the electrolyte - anode formed between a bad air film conductive layer, the anode overvoltage increases, causing anode effect. When adding a new alumina deposited on the anode and oxygen, the reaction of oxygen and carbon black, the anode surface gradually quiet, resistance is reduced, the electrolysis process and become normal.

After 40 years of research and development, electrolytic coloring to keep the depth and breadth of development, anodized aluminum is developed from the general protective - decorative purposes to the functional film special physical and chemical properties, from single colored salt to mixed salt coloring, from single uniform color to multi-colored, multi-color sense, and so on. Current porous alumina membranes toward functional direction research mainly from two aspects, one is the use of its porous structure, the development of new ultra-precision membrane; the other is through their nanoscale pores of various deposition the nature of different substances, such as metal-semiconductor, polymer materials, to prepare a new type of functional materials.

- Q:i need this for school and i need to know what are some advantages of stainless steel.

- It is great for knives because it stays chromed looking without rust. The steel is very hard so holds an edge for a long time. If it contains enough nickel it also is not magnetic, which some applications need this trait It is used for exhaust pipes in good cars, because it doesn't corrode from exhaust like common steel will, so the exhaust pipes last very long. Stainless is used for sinks, ovens, and kitchen appliances because it holds a shine, is very durable , doesn't crack or get burn holes like plastic would. It doesn't rust and is easy to clean and has a good color. It is used on exterior building panels for the same reason , plus it adds the same structural strength as regular steel without the maintenance of painting and rust removal. It is great for pans because you can scrub it without scraping it and it conducts heat well and cleans easily because the surface is smooth and hard So it has the same advantages of strength and fabrication as regular steel, without the downside of rust and ugliness. More cost (it contains chromium and nickel which are expensive) and harder to weld is two of it's shortcomings

- Q:I want to build an indoor riding arena, should I go for Steel ones.

- Though okorder /.. You can also have a look!!

- Q:How do steel coils contribute to the automotive aftermarket?

- The automotive aftermarket heavily relies on steel coils to manufacture a wide range of automotive parts and components. This secondary market deals with the sale of vehicle parts, accessories, and services after the initial purchase of the vehicle. Steel coils find their application in the production of several automotive aftermarket products, including springs, suspension components, chassis parts, and body panels. These coils are typically made from top-notch steel alloys that possess the desired characteristics of strength, durability, and performance. Springs are one of the primary uses of steel coils in the automotive aftermarket. These coiled springs play a crucial role in various automotive systems like suspension, brakes, and clutches. They provide the necessary support, stability, and shock absorption to ensure smooth and safe vehicle operation. Not only that, but steel coils also contribute to the manufacturing of chassis parts, which are vital for maintaining the vehicle's structural integrity and safety. Chassis parts made from steel coils include frame components, cross members, and reinforcement panels, which greatly enhance the overall stability and durability of the vehicle. Moreover, steel coils are extensively utilized in the production of body panels, such as doors, hoods, fenders, and roofs, which are commonly replaced or customized in the automotive aftermarket. These body panels, manufactured from steel coils, not only enhance the vehicle's aesthetics but also provide protection and resistance against impacts. In conclusion, steel coils play a critical role in the automotive aftermarket by facilitating the production of various parts and components necessary for vehicle repair, customization, and improvement. Their high strength, durability, and versatility make them an indispensable raw material, perfectly meeting the demanding requirements of the automotive industry.

- Q:I have a Charles Daly shotgun and I'm trying to find out if it is ok to shoot steel out of. The side engravings say: Charles Daly 20 GA 3 and the other side says : KBI-HBG, PA made in TurkeyOn their website it says that the barrel on the Charles Daly 300 Field is able to shoot steel but I don't see anywhere that this is a 300 model.Im also not sure if the choke is able to shoot steel. It has no engravings on it. How can I tell if this choke will work? It is the original choke that came with the gun?

- It's fine. Like .700 Nitro said, lead is a softer metal than steel. . BTW- Tom, grow up. I doubt you have ever been hunting in your life. What the he!! does someone's S.S number have to do with hunting? Nothing jack $$. Here's some advice for you- follow me around for a few days down here... It will cost you a little bit more than $15 per hour. Down here, a guy will actually realize that he as family jewels.

- Q:What are the different types of steel coil surface protection methods?

- There are several types of steel coil surface protection methods, including oiling, painting, galvanizing, and polymer coating. Oiling involves applying a thin layer of oil to prevent corrosion and rust. Painting involves using a protective paint coating to provide a barrier against moisture and other corrosive elements. Galvanizing involves coating the steel coil with a layer of zinc to provide corrosion resistance. Polymer coating involves applying a protective polymer film to prevent corrosion and improve durability.

- Q:Can steel coils be used in marine environments?

- Although steel coils can be utilized in marine environments, it is crucial to take necessary precautions to avoid corrosion. Given that steel is susceptible to corrosion when exposed to moisture and saltwater, which are commonly found in marine environments, it is imperative to employ protective measures on the steel coils. One such method is treating them with protective coatings like galvanization or painting to establish a shield between the steel and the corrosive elements. Moreover, regular maintenance and inspections should be conducted to detect any signs of corrosion and promptly address them to prevent further harm. By implementing these measures, steel coils can be effectively employed in marine environments while minimizing the risk of corrosion and ensuring their durability and performance.

- Q:Steel sticks- it has meaning to us -similar to my deceased father's name, Steven fits our style as people. We like the hardness of it for our little man. We need a middle name though. Open to suggestions, thank you=)

- Steel ___ Tompkins xavier jax stone blaise/blaze navarro dialo zorion soloman eron muron darko vincent wolf giovanni ryker/rykeir orvall oryan/orian isadore reese axel/axl xander/zander zane zeke dane xan/zan grayson griffin trayton urban sterling - probably wouldn't sound good with steel but its another choice you can have STOP HATING SHE SAID SHE DIDNT LIKE COMMON NAMES!

- Q:Does anyone know how to make a steel helmet, or does anyone know where to direct me websites-wise? i've just started looking on the web for info, so when i get back here i might've already found some info, but more wouldn't hurt, especially if from people who are interested on the subject. i know nothing about metallurgy, nothing on the art of metal working etc... please help.

- Steel okorder

- Q:okay i got some questions of the steel plow.1st - who inveneted it? where and when?2nd - how did it work? what is it used for? what is it made of? how is it produced?okay guys thank you very much. remember best answer gets best answer 10 points!

- If you're willing to substitute the word iron for steel (steel came a good bit later in history), the Girard plow from the 1300's in Belgium would be the first example known. It's named after the guy who invented it (Girard). How did it work? Like any other plow! You drag it along and it makes a trench of sorts in the ground! It was used for agricultural purposes. As for how it was produced, you need to look up the history of the Iron Age to understand how they started to use iron back in about 1200BC to make tools.

- Q:How are steel coils stored to prevent damage?

- Steel coils are typically stored in a way that minimizes the risk of damage. They are usually placed on pallets or in racks to keep them off the ground and provide stability. Additionally, they are often secured with bands or straps to prevent movement during storage and transportation. Proper ventilation is also important to prevent moisture buildup, which can cause corrosion. By implementing these measures, the risk of damage to steel coils is significantly reduced.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Galvanized Steel Sheet Coil from China High Quality

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords