FRP Pultrusion Roof Tile Sheets or Panels

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 500M2 m²

- Supply Capability:

- 900M2/Month m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

FRP Pultrusion Roof Tile Sheets or Panels

Description

In general, our company specializes in FRP grating, FRP decking, FRP platform and other products of FRP. We have a varity of FRP products sold over the country because we have our own teams of design, manufacturing and sales with hundreds of staffs.

At the same time, we are devoted to creating a production and marketing for FRP products, which has certain influence in China by proceeding with professional teams, rigorous quality management system and advanced production facility.

Today, we’re planning to win more market shares in the world and let more customers know us.

Photos

Product Traits

1. Corrosion resistance no rust, no maintenance, long service life.

2. Lightweight, high strength pultrusion process molding FRP profiles have high glass fiber content (60%). In this situation, the density of glass fiber reinforced plastic is only about a quarter of the steel.

3. The intensity and stiffness is quite prominent,.

4. Anti-fatigue high anti- fatigue strength, allowing repeated bending without permanent deformation.

5. Anti-aging select highquality FRP pultrusion profiles, the service life of the product can be more than 20 years.

6. Anti-UV agent are added into all pultrusion FRP profiles get the best anti-uv effect.

Product Advantage

Coated with prevent aging layer

Excellent insulating performance

Easy to maintain.

High strength.

Long service life.

Easy to install.

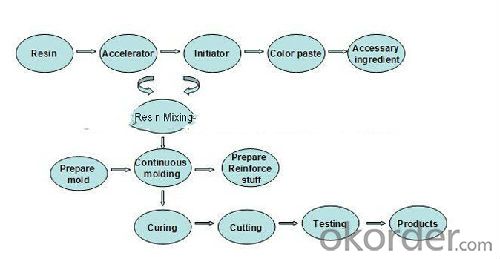

Production Process

Specification

Mechanical properties: high rigidity lighting panels

Plate matches: match with general prepainted galvanized sheet, galvanized steel

Resin composites: Improved anti-aging SMR198 resin

Fiber reinforcement: E-glass fiber untwisted without glue

Surface treatment: affixing MELINEX301 film

Stiffener line: surface with longitudinal uniform distribution of anti-LAC gluten

Glass fiber: not less than 28%

Unit Weight: 1800g / ㎡, 2400g / ㎡, 3050g / ㎡

Nominal thickness: 1.2 mm, 1.5mm, 2.0mm (tolerance ≤ 10%)

Temperature limits: -60 ℃ ~ +130 ℃

Transmittance (1.5mm): 72% ± 2% (fog white, sky blue, water green), 52% ± 2% (white porcelain)

UV-rate: 99%

Tensile strength: 90Mpa

Flexural strength: 160 Mpa

Elongation: 1.9%

Pap hardness: ≥ 50

Thermal expansion coefficient: 1.5 ~ 3.2 * 10-5 / K

Thermal conductivity: K = 0.23W / m * K

Guarantee: 15 years

NOTE: In special cases, the surface film varieties vary according to needs, such as Melinex389, PT055 and so on

FAQ

1.Which country do you mainly export to?

A: Our products are very popular in Mid East, India, South East Asia, Latin America, Africa.

2.Q: What’s the advantage of you compared with other suppliers experienced in foreign trade?

A: We have been specialized in FRP products for over decades years and approved by many domestic companies. Except for our quality and price, we’re also able to give you the best service.

3.Q:Can you provide some samples?

A: Yes, of course. We will send you samples for your confirmation before you place firm orders.

- Q:How does fiberglass fabric perform in insulation against sound?

- Fiberglass fabric is widely used in various applications including insulation against sound. It performs exceptionally well in reducing and absorbing sound waves due to its unique properties. The structure of fiberglass fabric consists of densely packed fibers, which helps in breaking down sound waves and reducing their transmission. As sound waves encounter the fabric, they are dispersed and absorbed by the fibers, preventing them from passing through to the other side. This absorption capability is crucial in creating a soundproof environment and reducing noise pollution. Furthermore, fiberglass fabric is known for its high density and low porosity. These properties contribute to its effectiveness in sound insulation. The dense structure of the fabric prevents sound waves from passing through, while the low porosity minimizes the amount of sound that can penetrate the fabric. This combination results in excellent soundproofing capabilities. Moreover, fiberglass fabric is a lightweight material, making it easy to install in various settings such as walls, ceilings, and floors. Its flexibility allows it to conform to different shapes and sizes, ensuring complete coverage and minimizing the risk of sound leakage. Additionally, fiberglass fabric is also known for its thermal insulation properties. This means that it not only helps in reducing sound transmission but also provides additional benefits by preventing heat transfer. This dual functionality is advantageous in applications where both soundproofing and temperature control are desired, such as in recording studios, theaters, or industrial settings. In summary, fiberglass fabric performs exceptionally well in insulation against sound. Its dense structure, low porosity, and absorption capabilities effectively reduce the transmission of sound waves. Its lightweight and flexible nature make it easy to install in various settings, while its thermal insulation properties provide additional benefits. Overall, fiberglass fabric is a reliable choice for soundproofing applications.

- Q:What are the different types of fiberglass fabrics?

- There are several different types of fiberglass fabrics available, each with its own unique characteristics and applications. Some common types include: 1. E-Glass Fabric: This is the most commonly used type of fiberglass fabric. It is known for its excellent electrical insulation properties and high tensile strength. E-glass fabric is used in a wide range of applications, including boat building, automotive parts, and aerospace components. 2. S-Glass Fabric: S-glass fabric is a higher-performance alternative to E-glass. It has a higher tensile strength and better resistance to impact, making it suitable for applications that require superior strength, such as military equipment and high-performance sports equipment. 3. C-Glass Fabric: C-glass fabric is resistant to chemical corrosion, making it ideal for use in applications where exposure to chemicals is a concern. It is commonly used in chemical plants, wastewater treatment facilities, and other industrial settings. 4. A-Glass Fabric: A-glass fabric is an alkali-resistant type of fiberglass fabric. It is commonly used in the construction industry for reinforcing cement and concrete structures, such as bridges and buildings. 5. Roving Fabric: Roving fabric consists of untwisted strands of fiberglass. It is typically used in applications that require high strength and dimensional stability, such as wind turbine blades, pipes, and pressure vessels. 6. Chopped Strand Mat (CSM): CSM is a type of fiberglass fabric made from randomly oriented chopped strands held together with a binder. It is commonly used in applications that require a smooth and uniform surface finish, such as boat hulls and automotive parts. 7. Woven Roving: Woven roving is a heavy-duty type of fiberglass fabric that consists of closely woven strands. It is known for its high strength and stiffness, making it suitable for applications that require structural reinforcement, such as boat hulls, wind turbine blades, and automotive body panels. Overall, the choice of fiberglass fabric depends on the specific requirements of the application, including strength, electrical insulation properties, chemical resistance, and surface finish.

- Q:Can fiberglass fabric be used for making shower curtains?

- Absolutely! When it comes to making shower curtains, fiberglass fabric is a stellar choice. Renowned for its durability, water resistance, and effortless upkeep, it's an ideal material. This fabric resists mildew and mold, which are frequent concerns in bathrooms, and can withstand the moisture and humidity found in shower areas. What's more, fiberglass fabric is a breeze to clean and doesn't absorb water, preventing saturation or unpleasant odors. All in all, opting for fiberglass fabric to create shower curtains ensures a lasting and hygienic solution for any bathroom.

- Q:What are the different laminating options available for fiberglass fabric?

- There are several laminating options available for fiberglass fabric, including epoxy, polyester, vinyl ester, and phenolic. Each option offers specific properties and benefits, such as improved strength, chemical resistance, and fire retardancy. The choice of laminating option depends on the intended application and desired performance characteristics.

- Q:Can fiberglass fabric be dyed or printed on?

- Yes, fiberglass fabric can be dyed or printed on. The process of dyeing or printing on fiberglass fabric involves using specialized dyes or inks that are designed to bond with the fibers of the fabric. This allows for vibrant colors and patterns to be applied to the fabric. However, it is important to note that the dye or ink used should be suitable for use with fiberglass and should be able to withstand the specific conditions or applications the fabric will be subjected to, such as high temperatures or exposure to chemicals. Additionally, it may be necessary to use specific techniques or equipment to ensure proper adhesion of the dye or ink to the fiberglass fabric. Therefore, it is advisable to consult with professionals who have experience with dyeing or printing on fiberglass fabric to ensure the best results.

- Q:How is fiberglass fabric used in the sports and recreation industry?

- Fiberglass fabric is widely used in the sports and recreation industry for its strength, durability, and flexibility. It is commonly used in the manufacturing of sports equipment such as fishing rods, hockey sticks, and tennis rackets, where it provides enhanced performance and resistance to breakage. Additionally, fiberglass fabric is also employed in the production of protective gear, such as helmets and body armor, due to its ability to absorb impact and provide excellent protection.

- Q:Can fiberglass fabric be used for insulation in storage tanks?

- Yes, fiberglass fabric can be used for insulation in storage tanks. It is commonly used due to its excellent thermal insulation properties, as it helps to maintain the temperature of the stored contents and prevent heat loss or gain. Additionally, fiberglass fabric is resistant to moisture, chemicals, and corrosion, making it a suitable choice for insulation in storage tanks.

- Q:Can fiberglass fabric be used for reinforcement in composite materials?

- Yes, fiberglass fabric can be used for reinforcement in composite materials. Fiberglass is a commonly used material in composites due to its high strength-to-weight ratio, corrosion resistance, and durability. The fabric is typically made from fine fibers of glass woven together, providing excellent tensile strength and flexibility. When combined with a matrix material such as epoxy resin, the fiberglass fabric reinforces the composite structure, enhancing its mechanical properties. This makes fiberglass fabric an ideal choice for industries such as aerospace, automotive, construction, and marine, where lightweight, strong, and durable materials are required.

- Q:Can fiberglass fabric be used for reinforcing plaster or stucco?

- Fiberglass fabric, when used for reinforcing plaster or stucco, can significantly enhance the strength and stability of the surfaces. This durable and robust material is commonly employed in construction projects to prevent cracks and bolster the overall durability of plaster or stucco. Typically, the fiberglass fabric is applied to the surface prior to the application of plaster or stucco, ensuring an even distribution of stress and minimizing the likelihood of cracking or crumbling. Moreover, fiberglass fabric possesses resistance against both moisture and weathering, rendering it an ideal choice for exterior applications, where plaster or stucco may face harsh environmental conditions. Ultimately, the utilization of fiberglass fabric in reinforcing plaster or stucco contributes to the improved structural integrity and longevity of the final surfaces.

- Q:Characteristics and advantages of polyester glass fiber cloth

- Delayed reflection crackDo not use polyester fiber surface will appear crack reflection in a few months, polyester fiber due to the elongation rate and instantaneous tensile strength is very low, can effectively eliminate the road junction or crack stress concentration, reduce the crack in the pavement and reflected upward, can delay the reflecting crack extend the life of the road, thereby greatly reducing the cost of repair and maintenance

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

FRP Pultrusion Roof Tile Sheets or Panels

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 500M2 m²

- Supply Capability:

- 900M2/Month m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords