FIBERGLASS WOVEN ROVING COMBO MAT 900g(600/300)

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Structure of woven roving combo mat Description:

◎ This mat is a combination of woven roving and chopped glass fiber. The layer of chopped strand is stitched together with woven roving by polyester thread. It is mainly applied in the processes of molding compressing, pultrusion, RTM, filament winding etc..

◎ This fabric is compatible with UP Resin, Vinyl ester resin, epoxy resin system etc. It is widely used in vehicle bodies and panels, marine (boat hulls and decks), pipeline, lamination and structural profiles

Main Features of the woven roving combo mat

◎ Increase strength, reduce product weight and better surface finish.

◎ low resin-consumption and faster wet-out.

◎ Good manufacturability and mechanical properties

◎ Improved fatigue and impact resistance

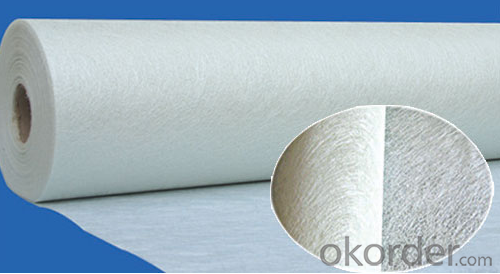

Woven roving combo mat Images

Woven roving combo mat Specification:

| ||||||||||||||||||||||||||||||||||||||||

FAQ of Woven roving combo mat:

Mainly be used as reinforced materials in the composite material industry.

• Matrix: unsaturated polyester resin, vinyl ester resin, epoxy resin and phenolic resin etc.

• Craft: pultrusion, RTM, hand lay up, etc.

• Ultimate products: pultruded profiles, FRP body of boat, insulation board, automobile body.

Delivery Detail: 15-21days

Other spec. can be custom made as per customer's request.

- Q:Can fiberglass mat tissue be used for flooring insulation?

- No, fiberglass mat tissue is typically not used for flooring insulation. It is more commonly used in applications such as roofing, wall insulation, and soundproofing. For flooring insulation, materials like foam, cellulose, or mineral wool are typically preferred.

- Q:Can fiberglass mat tissue be used for HVAC ducting?

- HVAC ducting can indeed utilize fiberglass mat tissue. This lightweight substance is formed by bonding glass fibers with resin. Its exceptional thermal insulation qualities render it suitable for HVAC systems that prioritize temperature control. Moreover, fiberglass mat tissue boasts resistance against moisture and chemicals, assuring long-lasting durability in ducting applications. Its installation is hassle-free, and it can be tailored to fit varied duct sizes and shapes. All in all, fiberglass mat tissue emerges as a dependable and effective option for HVAC ducting.

- Q:What are the potential environmental impacts of using fiberglass mat tissue?

- The potential environmental impacts of using fiberglass mat tissue can vary depending on several factors. One potential impact is the extraction and production of the raw materials needed to manufacture fiberglass. The process of obtaining glass fibers involves mining and processing silica sand, which can lead to habitat destruction, soil erosion, and water pollution. Additionally, the production of glass fibers requires a significant amount of energy, which often comes from non-renewable fossil fuels, contributing to greenhouse gas emissions and climate change. Another environmental impact of using fiberglass mat tissue is the release of hazardous chemicals during the manufacturing process. Fiberglass production involves the use of resins, binders, and other chemicals that can be harmful to human health and the environment. These chemicals may be released into the air, water, or soil, potentially contaminating nearby ecosystems and posing a risk to wildlife and human populations. Furthermore, the disposal of fiberglass mat tissue at the end of its life cycle can also have environmental implications. Fiberglass is not easily biodegradable, and proper disposal methods are crucial to prevent it from ending up in landfills or being incinerated, both of which can release harmful substances into the environment. Recycling fiberglass can be challenging due to its complex composition, leading to a significant portion of it being discarded improperly. Lastly, the use of fiberglass mat tissue in certain applications, such as insulation or construction materials, can contribute to energy consumption and greenhouse gas emissions. For example, fiberglass insulation can require additional energy for manufacturing, transportation, and installation compared to alternative insulation materials like cellulose or mineral wool. In conclusion, the potential environmental impacts of using fiberglass mat tissue are diverse and range from habitat destruction and pollution during raw material extraction to the release of hazardous chemicals during manufacturing and difficulties in disposal and recycling. It is essential for manufacturers and consumers to consider these impacts and explore alternative materials and production processes that minimize harm to the environment.

- Q:What are the different surface finishes available for fiberglass mat tissue?

- Some common surface finishes available for fiberglass mat tissue include smooth, textured, embossed, and matte finishes. These finishes can provide various aesthetic effects and enhance the performance of the fiberglass mat tissue in different applications.

- Q:Is fiberglass mat tissue resistant to chemicals?

- Generally, fiberglass mat tissue is resistant to chemicals. Its composition, comprising fine glass fibers bonded together with a resin, grants it exceptional chemical resistance properties. This resistance enables the fiberglass mat tissue to endure exposure to various chemicals without deteriorating or compromising its structural integrity. Nevertheless, it is crucial to acknowledge that the precise chemical resistance of fiberglass mat tissue may differ based on the type and concentration of the chemical it encounters. Therefore, it is advisable to consult the manufacturer's guidelines or perform suitable testing to ensure compatibility with particular chemicals.

- Q:Can fiberglass mat tissue be used for making lightweight automotive parts?

- Fiberglass mat tissue is indeed suitable for creating lightweight automotive parts. This material, known for its versatility, is widely used in the manufacturing process of automotive components. It boasts an impressive strength-to-weight ratio, making it perfect for producing durable and high-performing lightweight parts. Furthermore, the ease with which fiberglass mat tissue can be molded into different shapes allows for intricate and customized automotive designs. Its notable resistance to corrosion, chemicals, and temperature changes only adds to its suitability for automotive applications. In conclusion, fiberglass mat tissue is a dependable and cost-efficient option for crafting lightweight automotive parts.

- Q:What are the different color options available for fiberglass mat tissue?

- Various color options are offered for fiberglass mat tissue, catering to different preferences and applications. White, gray, black, and beige are among the commonly available colors. These color choices offer versatility in design and aesthetics, allowing users to select a color that enhances their individual project needs. Factors like UV resistance and desired visibility or camouflage levels can also influence the color selection. In conclusion, the availability of diverse color options for fiberglass mat tissue grants users the flexibility and customization opportunities necessary to achieve their desired results.

- Q:Can fiberglass mat tissue be used for repairing fiberglass truck beds?

- Yes, fiberglass mat tissue can be used for repairing fiberglass truck beds. It is commonly used in such repairs due to its strength, durability, and ability to bond well with the existing fiberglass surface.

- Q:What is the moisture resistance rating of fiberglass mat tissue?

- The moisture resistance rating of fiberglass mat tissue can vary depending on the specific product and manufacturer. However, in general, fiberglass mat tissue is known for its excellent moisture resistance properties. It is typically designed to be highly resistant to water absorption, making it suitable for use in applications where moisture exposure is a concern. This moisture resistance helps to maintain the structural integrity and performance of the fiberglass mat tissue, even in humid or wet conditions. It is important to note that when selecting fiberglass mat tissue for a specific application, it is recommended to refer to the product specifications provided by the manufacturer to determine the precise moisture resistance rating.

- Q:Are there any specific certifications or standards that fiberglass mat tissue must meet?

- Certifications and standards are necessary to guarantee the quality and appropriateness of fiberglass mat tissue for different purposes. The ASTM D 4601 standard is widely recognized and specifies the minimum requirements for glass fiber mats used in roofing and waterproofing systems. It covers various physical properties like weight, thickness, tensile strength, tear resistance, and water resistance. Apart from ASTM D 4601, fiberglass mat tissue may undergo testing based on its intended usage. For example, if it is used in the automotive industry, it may need to meet ISO 9001 or IATF 16949 standards, ensuring quality management systems and product consistency. Furthermore, fiberglass mat tissue used in construction or building materials should adhere to regulations set by organizations like the International Code Council (ICC), the American National Standards Institute (ANSI), or the Underwriters Laboratories (UL). These standards primarily focus on fire resistance, thermal insulation properties, and overall safety. Ultimately, the specific certifications and standards that fiberglass mat tissue must meet depend on its intended application and the industry it is used in. These standards are pivotal in ensuring the quality, performance, and safety of fiberglass mat tissue products.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

FIBERGLASS WOVEN ROVING COMBO MAT 900g(600/300)

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords