Fiberglass chopped strand mat high quality

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 100 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description

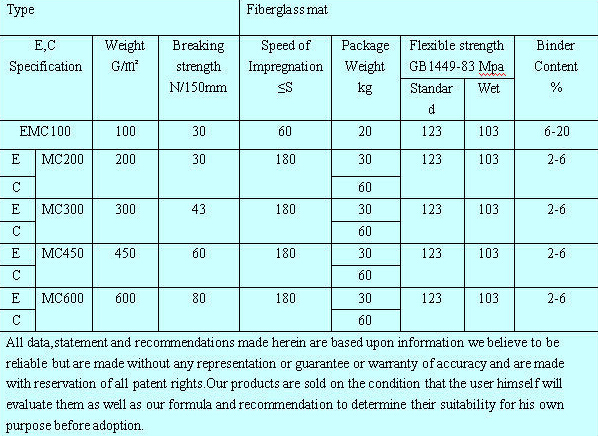

.The Style including the EMC100,EMC200,EMC600.EMCL600.EMCL450,CMC300.CMC450....

2.General width 1040mm/1270mm

3.chopped strand mat is made of randomly dispersed with power or emulsion bonded.

4.Applicable for hand lay -up ,continuous lamination process,compatible with UP VE

5.Suitable for transparent panels,ship ,bodies,automobile parts and interior decorations....

Style :

Packing :

each roll is packed by polyester bag .

2.Every roll in a cardbord box or thhr plastic woven bag

3.30kg with a rollof woven roving

4.Bordbox size : 22*24*114cm

5.The details as per customes requriments

- Q:What are the transportation considerations for fiberglass chopped strand?

- Transportation considerations for fiberglass chopped strand include ensuring proper packaging and securing the material to prevent damage during transit. Fiberglass chopped strand is typically packaged in bags or boxes, and it is important to choose packaging that is sturdy enough to withstand the rigors of transportation. In addition to packaging, it is essential to secure the fiberglass chopped strand properly to prevent shifting or movement during transport. This can be done by using straps or other secure fastening methods to hold the packages in place within the transportation vehicle. Another consideration is the weight and size of the fiberglass chopped strand packages. It is important to accurately estimate the weight and dimensions of the packages to ensure compliance with weight restrictions and to determine the appropriate type of transportation vehicle needed. Furthermore, it is crucial to consider any special handling requirements for fiberglass chopped strand during transportation. This may include protecting the material from extreme temperatures, moisture, or other environmental factors that could potentially impact its quality. Lastly, it is important to be aware of any regulations or guidelines that govern the transportation of fiberglass chopped strand. This could include compliance with hazardous materials regulations, if applicable, or following specific shipping requirements mandated by regulatory bodies. By considering these transportation considerations, it is possible to ensure the safe and efficient transportation of fiberglass chopped strand, minimizing the risk of damage or loss during transit.

- Q:What are the manufacturing tolerances for fiberglass chopped strand?

- The fiberglass chopped strand's manufacturing tolerances differ based on the specific product and its intended application. Nonetheless, in general, the tolerances are relatively stringent to guarantee consistent quality and performance. Typically, the length of the individual chopped strands falls within a narrow range, like +/- 5 mm or +/- 0.5%. This ensures uniformity in the reinforcement material, which is crucial for achieving desired mechanical properties in composite products. Similarly, the diameter or thickness of the chopped strands is controlled within specific tolerances to ensure consistent performance. This can be specified as a percentage deviation or an absolute value, such as +/- 0.1 mm or +/- 5%. Additional manufacturing tolerances for fiberglass chopped strand may include parameters like moisture content, fiber content, and tensile strength. These parameters are closely monitored during production to meet the desired specifications and ensure the final product's quality. It is important to note that the specific tolerances for fiberglass chopped strand may vary among manufacturers and can be customized to meet the requirements of different industries and applications. Therefore, when selecting a supplier, it is crucial to consider the specific tolerances and quality control measures they adhere to, as well as any industry standards or customer specifications that need to be met.

- Q:Is fiberglass chopped strand compatible with different resin systems?

- Yes, fiberglass chopped strand is compatible with different resin systems. Fiberglass chopped strand can be used with various types of resins such as polyester, epoxy, vinylester, and polyurethane. The compatibility between the fiberglass chopped strand and the resin system is crucial for achieving optimum mechanical properties and overall performance of the composite material. Proper selection of the resin system is essential to ensure good wetting and bonding of the chopped strands, which affects the strength, stiffness, and other properties of the final composite product. Manufacturers often provide guidelines and recommendations for the preferred resin systems to be used with their specific fiberglass chopped strand products to ensure compatibility and optimal performance.

- Q:Is fiberglass chopped strand compatible with thermoplastic resins?

- Yes, fiberglass chopped strand is compatible with thermoplastic resins.

- Q:Is fiberglass chopped strand suitable for the production of automotive spoilers?

- Yes, fiberglass chopped strand is suitable for the production of automotive spoilers. It is a commonly used material in the automotive industry due to its high strength-to-weight ratio, durability, and ease of molding into complex shapes. Additionally, fiberglass is resistant to corrosion and can be easily painted or coated to achieve the desired finish.

- Q:How does the toughness of the chopped strand affect its performance?

- The performance of the chopped strand is directly influenced by its toughness in several ways. Firstly, a higher level of toughness indicates a greater capability to withstand stress without breaking or failing. This means that a chopped strand with higher toughness can endure more strain or force before it fractures or tears. This is especially important in applications where the chopped strand experiences high levels of mechanical stress or impact, like in reinforced composites or structural components. Furthermore, the toughness of the chopped strand also affects its ability to maintain its integrity and mechanical properties over time. A higher level of toughness generally implies a superior ability to resist degradation or wear, ensuring that the chopped strand remains effective and reliable for a longer duration. This is of utmost importance in industries where durability and longevity are crucial factors, such as automotive, aerospace, or construction. Additionally, the toughness of the chopped strand can also impact its handling and processing characteristics. A higher level of toughness may make it more challenging to cut or manipulate the chopped strand during fabrication, necessitating specialized equipment or techniques. On the other hand, a lower level of toughness may make the chopped strand more susceptible to breakage or damage during handling, potentially leading to quality issues or decreased performance. To summarize, the performance of the chopped strand is directly influenced by its toughness, which determines its resistance to breakage, ability to maintain mechanical properties over time, and handling characteristics. Therefore, it is crucial to understand and optimize the toughness of the chopped strand to ensure its effectiveness and reliability in various applications.

- Q:What are the storage requirements for fiberglass chopped strand?

- To maintain the quality and integrity of fiberglass chopped strand, the main focus lies in its storage requirements. It is crucial to keep it in a dry and well-ventilated space to avoid moisture absorption, as excessive moisture can cause the material to degrade and perform poorly. Moreover, the storage area must be shielded from direct sunlight and extreme temperature changes, as these factors can also have adverse effects on its properties. It is advisable to store the chopped strand in its original packaging or securely sealed containers to safeguard it from dust, dirt, and other pollutants. By adhering to these storage guidelines, the fiberglass chopped strand can be preserved in prime condition, ensuring its effectiveness and long-lasting performance in various applications.

- Q:Can fiberglass chopped strand be used in the production of water tanks?

- Fiberglass chopped strand is indeed applicable for water tank production. Being a flexible material, fiberglass offers remarkable strength and endurance, rendering it suitable for a range of purposes, including water tanks. The form of fiberglass, in which strands or fibers are chopped into smaller pieces, can be effortlessly blended with resins or other binding agents to form composite materials with specific characteristics. These composites can be shaped into diverse forms, such as water tanks, providing a lightweight and robust solution. Moreover, fiberglass has resistance against corrosion, which is crucial for water tanks that are constantly in contact with water for extended periods. Consequently, employing fiberglass chopped strand in water tank manufacturing is a feasible choice that presents numerous benefits.

- Q:Can fiberglass chopped strand be used for reinforcing metal matrix composites?

- Yes, fiberglass chopped strand can be used for reinforcing metal matrix composites. Fiberglass chopped strand is made up of small glass fibers that are randomly oriented and held together with a binder. These fibers can be added to a metal matrix to increase its mechanical properties, such as strength and stiffness. The use of fiberglass chopped strand as a reinforcement in metal matrix composites offers several advantages. Firstly, fiberglass is a lightweight material, which helps to reduce the overall weight of the composite without compromising its strength. This is particularly beneficial in industries where weight reduction is critical, such as aerospace and automotive. Secondly, fiberglass chopped strand has a high tensile strength, which allows it to effectively distribute and transfer stress within the composite. This improves the composite's resistance to deformation and enhances its load-bearing capacity. Lastly, fiberglass chopped strand also provides excellent resistance to corrosion, which is essential in applications where the composite is exposed to harsh environments or chemical substances. However, it is important to note that the compatibility between the fiberglass chopped strand and the metal matrix must be considered. The metal matrix should have good wetting and adhesion properties to ensure a strong bond with the fiberglass fibers. Additionally, the composite fabrication process should be carefully optimized to achieve uniform dispersion and alignment of the fibers within the metal matrix. Overall, fiberglass chopped strand can be successfully used for reinforcing metal matrix composites, offering improved mechanical properties, weight reduction, and corrosion resistance.

- Q:Can fiberglass chopped strand be used in filtration applications?

- Filtration applications can utilize fiberglass chopped strand. Composed of randomly oriented small fibers bound together, fiberglass chopped strand forms a three-dimensional structure with a large surface area, making it ideal for filtration purposes. These fibers effectively capture and eliminate particles, contaminants, and impurities from fluids or gas streams. Fiberglass chopped strand finds application in various filtration systems, including air, water, oil, and chemical filters. Its strength, resistance to chemicals, and thermal stability enable it to meet demanding filtration requirements. Furthermore, fiberglass chopped strand can be easily molded or shaped into different sizes and forms, allowing for customization and compatibility with diverse filtration systems.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Fiberglass chopped strand mat high quality

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 100 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords