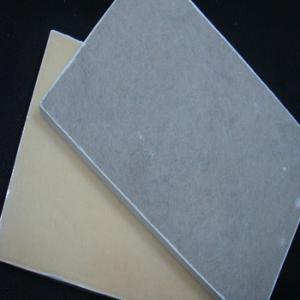

Fiberglass Ceiling Tiles with Square and Tegular Edges

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 120000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

The tile is made by high-density fiberglass with compound decoration wool on the surface and fiberglass wool on the back .The edges are painted. With the characteristics of square in edges and angle,it will be parallel to suspension system after installation.

The tile is made by high-density fiberglass with compound decoration wool on the surface and fiberglass wool on the back .The edges are painted. With the characteristics of square in edges and angle,it will be parallel to suspension system after installation.

Product Applications:

The panels are udes widely in schools, offices, music studios, lecture theatres,

multi purpose halls, interview rooms, training areas and cinemas. They meet the

requirements of BB93 of Building Regulations for acoustics in school buildings and

are Class O fire rated hence meeting the Fire Regulations as well.

Product Advantages:

Saves headroom space because exceptional noise absorption effectiveness is achieved by low (30mm) material thickness.

Surfaces can be emulsion painted to any colour without significant loss in noise

absorption. Increase savings due to fast and easy installation.Lightweight and therefore are ideal for adhering to ceilings, which do not have a very high load bearing capabilities.

Meets BB93 standards for school acoustics as well as common areas in flats for Building

Regulations.

Reinforced edges for increased durability.

Main Product Features:

Material: Torrefaction Compounded high density fiberglass wool

Face: Special painting laminated with decorative fiberglass tissue

Color: white, black and others to order

Fire-resistant: class A, non combustible

NRC: 0.9-1.0, excellent sound absorption

Thermal-resistant: >0.4 (m2k/w)

Humidity: Dimensionally stable with RH up to 95% at 40c, no sagging, wrapping, or delaminating

Moisture rete:<1% (JC/T670-2005)

Enviromental impact: Tiles and packing are fully recyclable

Product Specifications:

FAQ:

1)Q:Are you a factory or trading company?

A: We are a factory.

2)Q: I am interested in the products but I do not have experience

A: Tell us your budget and target market and we will give you professional advice of exact kinds and quantity.

3)Q: How can I get some samples?

A: We are honored to offer you samples.

4)Q:How does your factory do regarding quality control?

A: Quality is priority, we always attach great importance to quality controlling from every worker to

the very end.

Images:

- Q:I am spraypainting my basement ceiling black, I am also putting up drywall. I am not sure how to finish the space above the top of the wall, where I can see insulation between joists. Any thoughts are welcome.

- Spray Painting Basement Ceiling

- Q:What is the space body?

- In the humid environment, can also be used single or double perforated plate for the sound absorption layer (to increase the absorption of low frequency, perforation rate is generally less than 5%), instead of porous materials. ④ hanging pieces. Such as metal lugs, hooks, bolts and so on. When used, the surface are placed in the sound field, is conducive to give full play to the sound absorption of the material. The effective sound absorption area of ??a single sound absorber is much larger than the geometric projection area, so if the projection area is calculated, the sound absorption coefficient can be greater than one. The characteristic is usually expressed by the effective sound absorption, which depends not only on the nature of the body itself but also on the interval between the absorbers but not in a linear proportion. So the best design should be the use of the least sound absorber unit, get as much as possible sound absorption effect. It is generally believed that if the plate-like sound absorber is used, the total area is 30% -40% of the flat top area of ??the room, the sound absorption efficiency can reach the best value and the economic effect is the best. Space absorber is mainly used to reduce the reverberation time in the hall and factory workshop and the sound level of the reverberation field. It has many advantages such as flexible design, simple installation, convenient installation and beautiful appearance. But it should also be noted that only in the original indoor sound absorption is very small, reverberation field is very strong circumstances, and the noise reduction effect is usually not more than 10dB, generally between 3-8dB, the best will not exceed 15dB The

- Q:I had my house re roofed last year and the roof leaked into a large utility room. I took the drop ceiling out and took down the ceiling panels above it and now I have to replace the insulation and put a ceiling back in. Its a very high celing unless I replace the drop ceiling panels here. Any suggestions? What kind of insulation should I use? I noticed some of the insulation has different numbers and some of it is very expensive so how do I know what to use?

- The numbers associated with it are called R Value. As a rule of thumb, the higher R Value numbers, the better. For example, fiberglass has about R 3 per inch (least expensive) and rigid foam has about an R 6 per inch (most expensive). If you have plenty of space to work with, you could do 10 inches of fiberglass (or a similar mineral fiber type insulation) and get the same results as if you used 5 inches of foam. It just depends on your situation. If you are in a very cold climate, I would suggest insulating to an R 49. If you are in a very hot climate, I would suggest insulating to an R 19 with a radiant barrier (more efficient than R 30 in warm, sunny climates). If you are in a moderate climate, you could be anywhere in the middle.

- Q:Our basement family room has an insulated ceiling but the bedrooms do not. One bedroom is below a bathroom and it gets very loud because of a water waste pipe. We have a storage room that has open access to the ceiling space. It would be about 20ft that we would have to push insulation into. This seems like it would be very hard with traditional roll insulation. It would be very easy to put some lengths of soundboard or xps or something in, but I don't know if it would achieve the desired effect. Thanks in advance.

- XPS - expanded polystyrene - would be a poor choice for sound insulation. Better than nothing, but not a great result for the money compared to some other choices. Fiberglass insulation does a surprisingly good job of reducing sound transmission. Add a ceiling to the joists above: suspended noise attenuation board - ask around at musical instrument stores for suggestions where to get that - can help a lot but it's pricier than other ceiling choices, so limit its use to where it's needed most: right around that pipe. If you're really sick of the noise, go nuts: Frame for a box of acoustic ceiling to go right around that entire pipe. Acoustic ceiling, also called drop ceiling tiles, again isn't everything it could be but it has the advantages of being cheap and easy to install. Make a trough that goes up against the floor above and box in that pipe. You might lose some tiles in the event of a future leak, but no biggie: the tiles are cheap. Now insulate around the box and under the floor above, same as you did elsewhere in the basement. Now install a dropped ceiling in the entire space. The noise from the pipe will probably still be audible, but it should be nothing like what it was.

- Q:We have removed our rough sawn cedar from our cathedral ceiling in our 80's home. We found fiberglass insulation and 2x6 joists (the roof is directly above). The first electrician came out before we removed the ceiling and assumed there was no insulation and said we needed to get spray insulation because of the condensation can lights can cause. The other electrician we called out came after we removed the ceiling and did not say anything about condensation. Neither said anything about ice dams. I am seeing all this pretty scary stuff when doing my research, and am thinking we shouldn't put in recessed lighting now! We live in Wyoming where the climate can be pretty cold, but is usually very dry.So, if we use LED lamps and IC airtight housings, will the heat transfer really be bad enough to cause condensation and/or ice dams? Would it help to put some foam board between the shallow housings and the roofing substrate (if it fits)? We are only planning on putting up 6 6&quot; lights in a 10x20 room...

- You have to get the right kind of lights. LED lights don't get all that hot, but unless they're made for zero clearance, yes they do need some airspace around them. They make some with no need for airspace around them. They have an additional can around them to allow the space they need. Get the right kind, no problems, get the wrong kind, lots of problems.

- Q:Large area gypsum board light with no blockboard solid

- It is only nails or screws fixed on the wooden frame or metal shelves above. Safe and secure.

- Q:what is ceiling soundproofing?

- Usually, it's fiberglass insulation that's installed between the ceiling joists. If it's a multi-story building, the insulation absorbs sound from the floor above, so you don't hear it so much on the floor below.

- Q:Renovation of living room wall with steel bricks

- In the case of wet paste can hit the drill drill, no problem. And then safe point is to buy a glass drill on it. Then there is no problem.

- Q:Who has a building decoration materials Daquan, including indoor and outdoor. It is best to detail the classification, there are pictures the best.

- cleaning tools 1 wash basin: sub-table basin, column basin, hanging basin Wash basin main brands: Kohler, TOTO, American Standard, Wrigley, Slomime, Osman 2 Toilet: roughly divided: washed down, suction macro type Toilet main brands: Kohler, TOTO, American Standard, Wrigley, 3 Bathtub: roughly divided: steel enamel bathtub, cast iron bathtub, acrylic bathtub Usually the bath size: length 1100--1700 range 4 shower room function can be divided into three kinds: bath screen, computer steam room, the overall shower room 5 Sink type: stainless steel sink, artificial crystal stone, granite mixed sink 6 faucet The following are the same as the " Wallpaper type Paper wallpaper 2. clinker wallpaper 3. Textile wallpaper 4. Natural material wallpaper 5. fiberglass wallpaper 6. Metal film wallpaper 7. Liquid wallpaper

- Q:i am living in a ground storey house and there's no construction on top of my house. therefore it's very hot in summer and winter is normal.please help me to elaborate any procedure or material for cooling my top (ceiling) . i would be very grateful. thanks and regards.

- Don't know where you are or what type of roof we're talking about, but I would say an elastomeric roof coating would do the trick.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Fiberglass Ceiling Tiles with Square and Tegular Edges

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 120000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords