Electrolytic Tinplate ETP Sheets in good price for Food Cans

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 20000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Tinplate, as the name suggests, is coated on both sides with pure tin at various coating weights between 1 and 12 grams per square meter.

It has an extremely beautiful metallic luster as well as excellent properties in corrosion resistance, solder ability, and weld ability.

TINPLATE SHEET SPECIFICATION

Reference standard: GB/T 2520-2000, JIS G3303-2002 and DIN EN 10203-1991

Raw material: MR and SPCC

Thickness: 0.13 to 0.5mm

Width: 600-1050mm

Length: maximum 1200mm

Temper: T1~T5, DR8~DR10

Tin coating: 1.1g~11.2g We can produce according to customer’s requests.

Applications: paint, chemical and other usage can make battery, electric cable and other industries

Package: anti-rust paper, corner protected. Sheets or coils according customer's requests

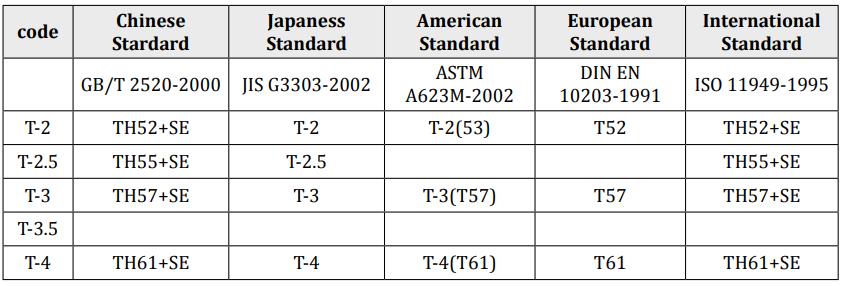

Stardard

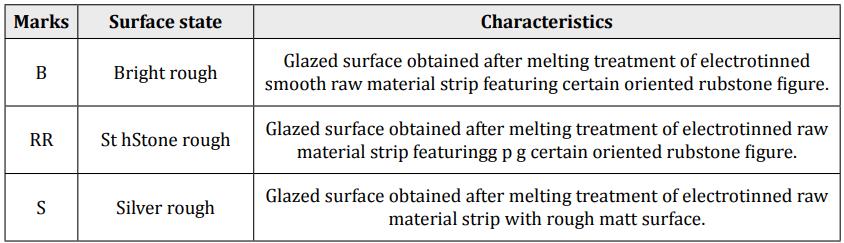

Surface

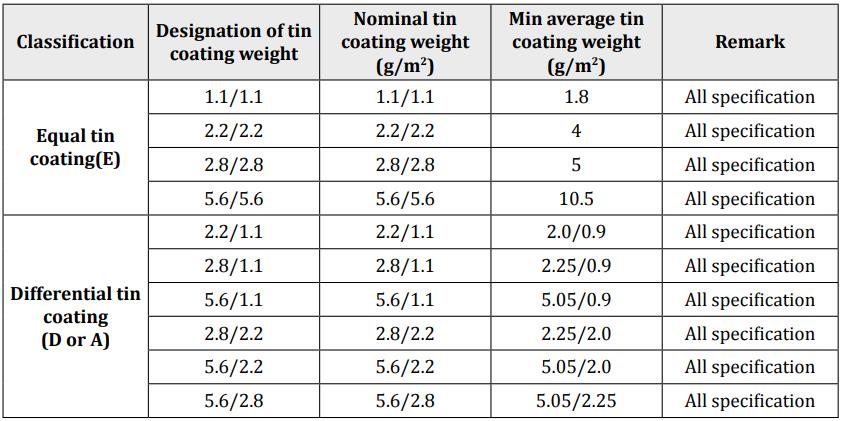

Coating

APPLICATION

Tinplate is widely used for making all types of containers, electrical machinery parts and many other products.

◆ Chemicals and painting cans

◆ Dry food cans, such as fancy cans, biscuit cans, milk powder cans, tea cans

◆ Liquid food cans, such as edible oil cans, beverage cans, Tomato paste cans

◆ Sea food cans

◆ Crown corks, easy open ends (EOE)

◆ Electrical machinery parts

◆ Bakeware and household kitchen parts

- Q:How does tinplate contribute to sustainability efforts?

- Tinplate contributes to sustainability efforts in several ways. Firstly, it is a highly recyclable material, which means that it can be reused multiple times without losing its properties. This helps reduce the demand for new raw materials and minimizes waste generation. Additionally, tinplate is often used as packaging material for food and beverages, providing a protective and durable barrier that extends the shelf life of products, reducing food waste. Furthermore, tinplate cans are lightweight, making them more energy-efficient during transportation, thus reducing carbon emissions. Overall, tinplate's recyclability, protective properties, and energy efficiency make it a sustainable choice for various industries.

- Q:What are the main differences between tinplate and tinplate laminates in terms of product visibility?

- The main difference between tinplate and tinplate laminates in terms of product visibility is that tinplate is a single-layer material made entirely of tin, while tinplate laminates are a combination of tinplate and other materials such as plastic or paper. Tinplate has a higher level of product visibility due to its shiny and reflective surface, allowing the contents of the package to be easily seen. On the other hand, tinplate laminates may have reduced product visibility as the additional layers of material can obstruct the view.

- Q:Can tinplate be used for packaging liquid products?

- Yes, tinplate can be used for packaging liquid products. Tinplate is a type of steel coated with a thin layer of tin, which provides excellent corrosion resistance and barrier properties. It is commonly used for packaging liquid products such as food, beverages, and chemicals as it helps to preserve the quality and freshness of the contents.

- Q:How long does tinplate take to corrode?

- The rate at which tinplate corrodes depends on various factors such as environmental conditions, exposure to moisture, and the presence of corrosive agents. Generally, tinplate is known for its excellent resistance to corrosion, and it can take several years or even decades before any significant corrosion occurs. However, it is important to note that the protective tin coating can wear off over time, making the underlying steel susceptible to corrosion. Regular maintenance and proper storage can help prolong the lifespan of tinplate and prevent corrosion.

- Q:How does tinplate contribute to the overall durability of packaging?

- Tinplate contributes to the overall durability of packaging through its inherent strength, corrosion resistance, and ability to withstand extreme temperatures. It provides a protective barrier against moisture, oxygen, and light, which helps to preserve the quality and freshness of packaged goods. Additionally, tinplate's resistance to impact and puncture ensures that the packaging remains intact during handling, transportation, and storage, thereby extending the lifespan of the product.

- Q:Can tinplate be used for non-food products?

- Yes, tinplate can be used for non-food products. Tinplate is a versatile material commonly used in various industries such as packaging, construction, automotive, and electronics. It is durable, corrosion-resistant, and has excellent formability, making it suitable for a wide range of non-food applications like cans, containers, aerosol cans, electrical components, and decorative items.

- Q:What are the advantages of using tinplate in packaging?

- Tinplate offers several advantages in packaging. Firstly, it provides excellent protection against corrosion, ensuring the contents remain safe and unaffected. Additionally, tinplate is lightweight yet durable, making it easy to transport and handle without compromising strength. It is also highly malleable, allowing for intricate designs and shapes, enhancing visual appeal. Furthermore, tinplate is eco-friendly as it is recyclable and can be reused multiple times, promoting sustainability in packaging solutions.

- Q:Can tinplate be painted or printed on?

- Yes, tinplate can be painted or printed on.

- Q:How does tinplate contribute to the convenience of pet care products?

- Tinplate contributes to the convenience of pet care products through its durability, versatility, and ability to preserve the quality and freshness of the products. Tinplate packaging ensures that pet food, treats, and other products remain safe and protected from moisture, light, and oxygen, prolonging their shelf life. Additionally, tinplate cans and containers are easy to open and reseal, providing pet owners with a convenient and hassle-free experience when using these products for their pets.

- Q:How to quickly distinguish tinplate and ordinary substrate iron?

- Tinplate is tin coil, measurement of tin content?. The base plate is a plain hard rolled coil, which is relatively hard without annealing.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Electrolytic Tinplate ETP Sheets in good price for Food Cans

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 20000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords