E-glass Fiberglass Woven Roving 600g-1000mm

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 5000 kg

- Supply Capability:

- 300000 kg/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Structure of woven roving Description

1,high strenth,corosion and resistence

2,consistent thickness,no fuzz

3,rapid impregnating

Glass woven rovings are bidirectional fabric by direct rovings in plain weave pattern. They are applicable for hand lay-up, winding and compress molding process, suitable for manufacturing tank, boat, automobile parts and other FRP products.

Main Features of the woven roving

1)Drapes well to suit the surface of intricate moulds

2)Fast wet-through and wet out

3)Easy handing and better appearance of the composite parts

4)Compatible with Unsaturated polyester resin

5)Very high laminate strength properties

Woven roving Images

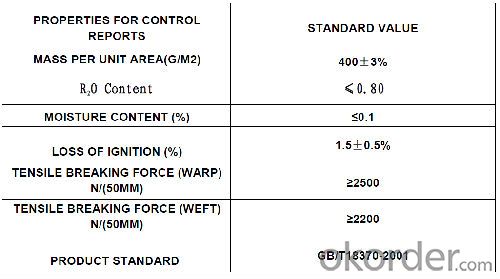

Woven roving Specification:

FAQ of woven roving:

Delivery Detail: 15-21days

Other spec. can be custom made as per customer's request.

- Q:What is the cost of fiberglass mat tissue?

- The cost of fiberglass mat tissue can vary depending on factors such as the thickness, size, and brand. It is best to check with suppliers or retailers for specific pricing information.

- Q:Can fiberglass mat tissue be used for repairing fiberglass kayaks?

- Yes, fiberglass mat tissue can be used for repairing fiberglass kayaks. Fiberglass mat tissue is a lightweight material that is commonly used in the repair and reinforcement of fiberglass products, including kayaks. It is designed to be easily moldable and conform to the shape of the damaged area. By applying the fiberglass mat tissue with an epoxy resin, it can effectively reinforce and bond the damaged sections of a fiberglass kayak, restoring its strength and durability. It is important to ensure that the damaged area is properly prepared and the fiberglass mat tissue is applied correctly to achieve a strong and long-lasting repair.

- Q:Is fiberglass mat tissue suitable for automotive interiors?

- Yes, fiberglass mat tissue can be suitable for automotive interiors. Fiberglass mat tissue is a versatile material that is commonly used in various industries, including automotive manufacturing. It offers several benefits that make it suitable for automotive interiors. Firstly, fiberglass mat tissue provides excellent insulation properties. It helps in reducing noise, vibration, and harshness (NVH) levels inside the vehicle cabin. This can significantly enhance the overall comfort and driving experience for passengers. Secondly, fiberglass mat tissue is lightweight and flexible, making it easy to install in different areas of the car interior. It can be molded and shaped to fit various parts, such as door panels, headliners, trunk liners, and floor carpets. Its flexibility also allows for easy integration with other components, such as sound-deadening materials, to further improve insulation and reduce vibrations. Additionally, fiberglass mat tissue is resistant to heat, moisture, and chemicals, which are often present in automotive environments. This makes it a durable and long-lasting material that can withstand the unique conditions inside a vehicle. It is also resistant to mold and mildew growth, ensuring a clean and hygienic interior. Furthermore, fiberglass mat tissue can be easily coated or laminated with other materials to enhance its aesthetic appeal. It can be finished with various fabrics, vinyl, or leather to match the desired interior design and provide a luxurious feel. In summary, fiberglass mat tissue is a suitable material for automotive interiors due to its insulation properties, lightweight and flexible nature, durability, resistance to heat and moisture, and potential for aesthetic enhancements. Its usage can contribute to creating a comfortable, quiet, and visually appealing cabin space for vehicle occupants.

- Q:Is fiberglass mat tissue suitable for marine applications?

- Fiberglass mat tissue is indeed appropriate for marine applications. Its durability, strength, and ability to resist water and corrosion make it a popular choice in the marine industry. This lightweight material is perfect for boat construction and repairs. It also offers exceptional resistance against UV rays, chemicals, and harsh weather conditions commonly found in marine environments. Additionally, it provides outstanding structural reinforcement and can be easily shaped and molded to suit different marine components. All in all, fiberglass mat tissue is a dependable and adaptable material for marine uses.

- Q:Can fiberglass mat tissue be used for repairing fiberglass structures?

- Fiberglass structures can be repaired using fiberglass mat tissue. This material is widely used in the construction and repair of fiberglass structures because of its versatility. Its purpose is to strengthen and reinforce damaged areas of the structure. To ensure a durable repair, the mat tissue is usually applied with resin, which bonds the fibers together. It is particularly effective for fixing cracks, holes, and other damages on fiberglass surfaces. In summary, fiberglass mat tissue is an outstanding option for repairing fiberglass structures due to its strength, flexibility, and ability to adapt to different shapes and sizes.

- Q:Can fiberglass mat tissue be used in marine applications?

- Yes, fiberglass mat tissue can be used in marine applications. It is commonly used in boat building and repair due to its excellent strength, corrosion resistance, and durability in marine environments.

- Q:What is the UV resistance of fiberglass mat tissue?

- The UV resistance of fiberglass mat tissue can vary depending on the specific formulation and manufacturing process used. Generally, fiberglass mat tissue is known for its excellent resistance to ultraviolet (UV) radiation. The fiberglass strands used in the mat are typically coated with a resin or binder that provides added protection against UV degradation. This coating helps to prevent the fibers from breaking down or becoming brittle when exposed to sunlight. Additionally, the structure of the fiberglass mat tissue itself provides a degree of natural UV resistance due to its dense and tightly woven construction. However, it is important to note that prolonged exposure to intense UV radiation can still cause some degree of degradation over time. Therefore, it is recommended to consult the specific product specifications or manufacturer's guidelines for accurate information on the UV resistance of a particular fiberglass mat tissue.

- Q:What is the expected lifespan of fiberglass mat tissue in outdoor applications?

- The expected lifespan of fiberglass mat tissue in outdoor applications can vary depending on several factors such as exposure to weather conditions, maintenance, and quality of the material. However, on average, fiberglass mat tissue can last for approximately 20 to 30 years when properly installed and maintained.

- Q:Can fiberglass mat tissue be used for insulation in refrigeration systems?

- Indeed, insulation in refrigeration systems can be accomplished by employing fiberglass mat tissue. Fiberglass, renowned for its remarkable thermal characteristics and moisture resistance, is a prevalent choice for insulation purposes. Specifically engineered to provide insulation, fiberglass mat tissue finds frequent application in the construction of refrigeration systems. Its purpose is to reduce heat transfer and uphold the desired temperature within the system. Moreover, fiberglass possesses the advantages of being lightweight, long-lasting, and easily installable, rendering it a favored option for refrigeration system insulation.

- Q:Is fiberglass mat tissue suitable for wastewater treatment applications?

- Yes, fiberglass mat tissue is suitable for wastewater treatment applications. Fiberglass mat tissue is a material that is resistant to chemicals, corrosion, and degradation, making it an ideal choice for various industrial applications, including wastewater treatment. It can be used as a filtration media to separate solid particles from wastewater, as a lining material to prevent corrosion in tanks and pipes, and as a reinforcement material for concrete structures used in wastewater treatment plants. Additionally, fiberglass mat tissue has excellent mechanical strength, dimensional stability, and thermal resistance, which further enhance its suitability for wastewater treatment applications. Overall, fiberglass mat tissue is a reliable and effective material for use in wastewater treatment processes.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

E-glass Fiberglass Woven Roving 600g-1000mm

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 5000 kg

- Supply Capability:

- 300000 kg/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords