E-glass Fiberglass Cloth

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Structure of Fiberglass Cloth Description:

1.The fabric of fiberglass cloth is woven by fiber glass yarn, which is treated with silane coupling agent, the kind of weave is plain.

2.It is base material of high strength,low extensibility,coating with resin

easily and surface flat and so on.

Main Features of the Fiberglass Cloth:

It has good characteristics of high tensile strength, stable tension, and no defect appearance. The fiberglass fabric can be widely applied in different industrial application such as: PTFE, silicon, PVA, PVC, PU and acrylic coating, thermal, insulation and others application.

Fiberglass Cloth Images:

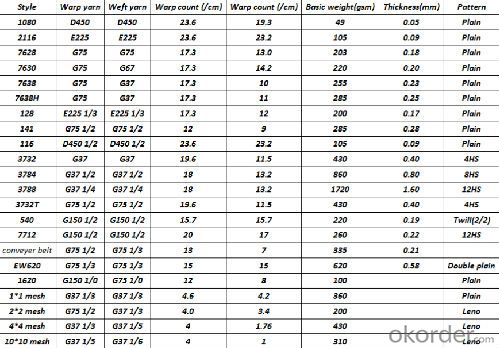

Fiberglass Cloth Specification:

FAQ of Fiberglass Cloth:

Delivery Detail: 15-21days

Other spec. can be custom made as per customer's request.

- Q:Can fiberglass fabrics be used for insulation in buildings?

- Indeed, insulation in buildings can be achieved using fiberglass fabrics. These fabrics consist of delicate glass fibers intricately woven together, and they are widely utilized as a means of thermal insulation. Their ability to minimize heat transfer is remarkable, allowing for a cozy atmosphere during chilly winters and a cool environment during scorching summers. Furthermore, fiberglass fabrics possess a lightweight nature, making installation effortless, and their exceptional resistance to fire makes them a highly sought-after option for insulation in various types of structures, be it residential, commercial, or industrial.

- Q:What are the different weaves available for fiberglass fabric?

- There are several different weaves available for fiberglass fabric, each with its own unique characteristics and uses. Some of the most common weaves include plain weave, twill weave, satin weave, and leno weave. Plain weave is the simplest and most common weave used for fiberglass fabric. It is characterized by an equal number of warp and weft yarns crossing over and under each other in a simple over-under pattern. This weave creates a strong and balanced fabric with good stability and durability. Twill weave is another popular option for fiberglass fabric. In this weave, the warp and weft yarns cross over and under each other in a diagonal pattern, creating a distinctive diagonal ribbing effect. Twill weave provides better drapability and flexibility compared to plain weave, making it suitable for applications that require greater conformability. Satin weave is a more complex weave that produces a smooth and shiny surface on the fabric. It is characterized by long floats of the warp or weft yarns, which means that fewer yarns are interlaced, resulting in a more flexible and lightweight fabric. Satin weave is often used in applications where a high-quality appearance and a soft feel are desired, such as in the production of clothing or decorative fabrics. Leno weave is a unique weave that involves twisting adjacent warp yarns around each other to create a stable and open mesh structure. This weave is commonly used for fiberglass fabrics that require high transparency and breathability, as well as for applications that involve filtration or reinforcement purposes. Overall, the choice of weave for fiberglass fabric depends on the specific requirements of the application. By considering factors such as strength, flexibility, appearance, and breathability, one can select the most suitable weave to achieve optimal performance in their desired application.

- Q:Is fiberglass fabric resistant to electrical conductivity?

- Yes, fiberglass fabric is resistant to electrical conductivity.

- Q:What is Teflon?

- As Tie Fulong, Teflon, Teflon, Teflon and so on (all Teflon transliteration). Teflon (Tie Fulong) coating is a kind of high performance coating is the one and only, with heat resistance, chemical inertness and excellent insulation stability and low friction, the comprehensive advantages with other coatings can not compete, the flexibility makes it can be used in almost all the shape and size of the products.

- Q:Do fiberglass fabrics have any electrical conductivity properties?

- No, fiberglass fabrics do not have any electrical conductivity properties. Fiberglass is an insulator and does not conduct electricity. This property makes it suitable for various applications where electrical insulation is required, such as electrical insulation sleeves, circuit boards, and protective covers for electrical equipment. Additionally, fiberglass fabrics are often used in industries where insulation from heat and fire is necessary, further highlighting their non-conductivity to electricity.

- Q:Can fiberglass fabric be used for reinforcement in wind turbine blades?

- Yes, fiberglass fabric can be used for reinforcement in wind turbine blades. Fiberglass is a commonly used material in the construction of wind turbine blades due to its high strength-to-weight ratio, durability, and corrosion resistance. The fabric is typically made from layers of woven or non-woven fiberglass fibers that are impregnated with a resin to form a composite material. This composite is then used to reinforce the structure of the wind turbine blades, providing them with the necessary strength and stiffness to withstand the dynamic loads and stresses experienced during operation. Additionally, fiberglass fabric can be easily molded into complex shapes, making it suitable for the aerodynamic design requirements of wind turbine blades. Overall, fiberglass fabric is a popular choice for reinforcement in wind turbine blades due to its mechanical properties and manufacturing versatility.

- Q:How does fiberglass fabric perform in terms of puncture resistance?

- Fiberglass fabric performs exceptionally well in terms of puncture resistance. Due to its unique composition of intertwined glass fibers, it offers a high level of durability and strength against puncturing forces. The tightly woven structure of fiberglass fabric makes it highly resistant to penetration by sharp objects, such as nails or needles. Additionally, fiberglass fabric is known for its ability to maintain its structural integrity even after being punctured, preventing further tearing or damage from occurring. This makes it an ideal choice for applications where puncture resistance is crucial, such as in protective clothing, industrial equipment, or reinforcement materials for composites. Overall, fiberglass fabric is highly reliable and effective in withstanding puncture forces, ensuring long-lasting performance and protection.

- Q:What are the advantages of using fiberglass fabric in composites?

- There are several advantages of using fiberglass fabric in composites. Firstly, fiberglass fabric is lightweight, which makes it ideal for applications where weight reduction is important. Secondly, it has high tensile strength, meaning it can withstand high amounts of stress without breaking. Additionally, fiberglass fabric is highly resistant to corrosion, chemicals, and UV radiation, enhancing the durability and longevity of composite materials. Lastly, fiberglass fabric is relatively low in cost compared to other composite materials, making it a cost-effective choice for various industries.

- Q:Can fiberglass fabric be used for making gloves?

- Gloves can indeed be made using fiberglass fabric. This material is known for its strength and durability, offering exceptional resistance against heat and fire. Its usage is prevalent in industries that demand protection against high temperatures or when working with hot objects. By weaving or knitting fiberglass fabric, gloves can be created to form a shield against heat, sparks, and flames, safeguarding the hands. Nevertheless, it is crucial to bear in mind that fiberglass may cause skin irritation and itchiness. Therefore, it is imperative to observe appropriate precautions and safety measures while utilizing gloves made from fiberglass fabric.

- Q:What are the different thickness options for fiberglass fabric rolls?

- The thickness options for fiberglass fabric rolls can vary, but commonly range from 0.5 oz to 6 oz per square yard.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

E-glass Fiberglass Cloth

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords