Customized Aluminum Profile for Closet Door

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20 m.t.

- Supply Capability:

- 2000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Structure of Customized Aluminum Profile for Closet Door Description:

Customized Aluminum Profile for Closet Door (also spelled anodising, particularly in the UK and Australia) is an electrolytic passivation process used to increase the thickness of the natural oxide layer on the surface of metal parts. Anodized aluminium surfaces, for example, are harder than aluminium but have low to moderate wear resistance that can be improved with increasing thickness or by applying suitable sealing substances.

2.Main Features of the Customized Aluminum Profile for Closet Door:

High corrosion-resistance;

weather-resistance;

heat-resistance;

alkali-resistance and impact-resistance properties.

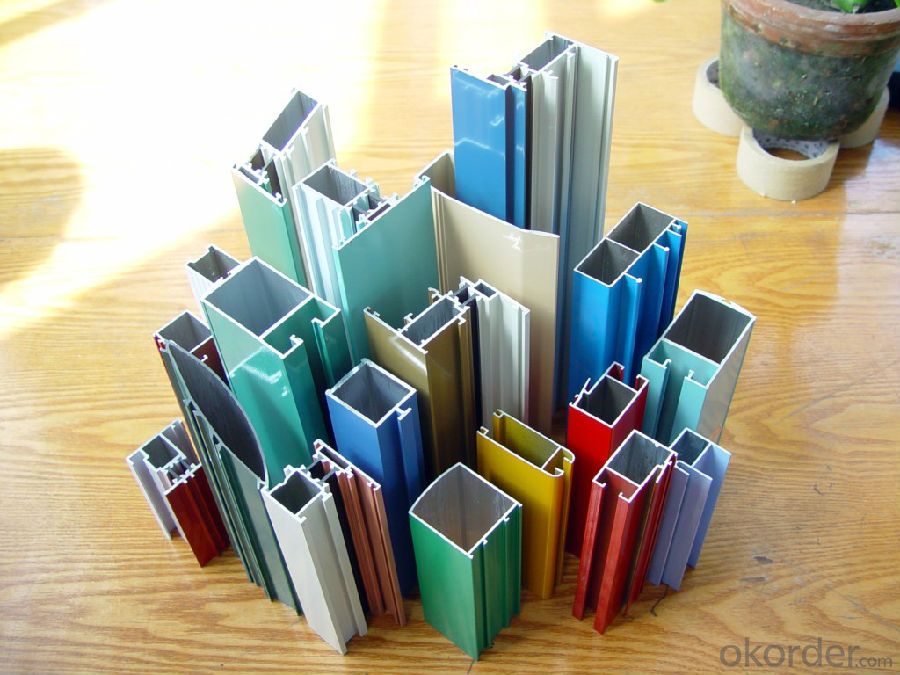

3.Customized Aluminum Profile for Closet Door Images:

4.Customized Aluminum Profile for Closet Door Specification:

1. Material: 6063,6061,6060,6005,6005A,etc.

2. Temper: T5 or T6

3. Finish: Mill finish, anodizing, powder coating, electrophoresis, wooden transfer or pvdf/carbon-flouride coated, polishing, brushing, sand blasting

4. Various colors: Silver, bronze, black, gold, blue, grey, champagne, bright, etc.

5. Machining: Cutting, punching, drilling, tapping, milling, bending, welding, CNC etc.

5.FAQ:

①How about your company?

A world class manufacturer & supplier of castings forging in carbon steel and alloy steel,is one of the large-scale professional investment casting production bases in China, consisting of both casting foundry forging and machining factory. Annually more than 8000 tons Precision casting and forging parts are exported to markets in Europe, America and Japan. OEM casting and forging service available according to customer’s requirements.

②How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

- Q:Can aluminum coils be used in the production of aluminum composite ceilings?

- Yes, aluminum coils can be used in the production of aluminum composite ceilings. Aluminum coils are often used as the base material for manufacturing aluminum composite panels, which are then used to create ceilings. These coils are typically made of high-quality aluminum alloy and have undergone various processes to ensure their strength, durability, and aesthetic appearance. The aluminum coils are coated with a protective layer, such as PVDF or polyester, to enhance their resistance to weathering, UV rays, and corrosion. This coating also allows for a wide range of color options, providing flexibility in design choices for aluminum composite ceilings. Overall, aluminum coils are an essential component in the production of aluminum composite ceilings, offering a lightweight, fire-resistant, and long-lasting solution for various architectural and interior design applications.

- Q:Just wondering if an aluminum and Fluoride bond can be created by boiling fluoridated water in aluminum cookware?

- Yes. okorder /

- Q:Are aluminum coils resistant to abrasion?

- Aluminum coils are typically resistant to abrasion, thanks to their durability and ability to withstand wear and tear. Known for its high strength-to-weight ratio and exceptional corrosion resistance properties, aluminum is well-suited for applications that demand abrasion resistance. Moreover, protective finishes are commonly applied to aluminum coils, further bolstering their ability to resist abrasion. Nevertheless, the exact level of resistance can vary depending on the particular alloy and surface treatment used on the coils.

- Q:Are aluminum coils resistant to abrasion?

- Aluminum coils are typically resistant to abrasion, thanks to their durability and ability to withstand wear and tear. Known for its high strength-to-weight ratio and exceptional corrosion resistance properties, aluminum is well-suited for applications that demand abrasion resistance. Moreover, protective finishes are commonly applied to aluminum coils, further bolstering their ability to resist abrasion. Nevertheless, the exact level of resistance can vary depending on the particular alloy and surface treatment used on the coils.

- Q:What are the common maintenance practices for aluminum coils?

- Some common maintenance practices for aluminum coils include regular cleaning to remove dirt and debris, checking for any signs of corrosion or damage, ensuring proper airflow and ventilation around the coils, and regular inspections to identify and address any potential issues. Additionally, it is important to follow manufacturer guidelines and recommendations for maintenance and to schedule professional servicing when necessary.

- Q:How are aluminum coils processed for specific mechanical properties?

- Aluminum coils are processed for specific mechanical properties through various methods such as heat treatment, cold working, and alloying. Heat treatment involves heating the coils to specific temperatures and then cooling them rapidly or slowly to enhance their strength, hardness, or ductility. Cold working, which includes processes like rolling or drawing, applies pressure to the coils to increase their strength and improve their mechanical properties. Alloying the aluminum coils with other elements can also modify their mechanical properties by enhancing their strength, corrosion resistance, or other desired characteristics. Overall, a combination of these processes is employed to achieve the desired mechanical properties in aluminum coils.

- Q:I want to paint my cars rims and grill metallic pink. But supposedly paint doesn't stick well to aluminum. What can I do to make it stick better and not chip?

- The best way is to have the pieces powder coated. Its a little expensive but the color and luster are outstanding and will last forever.

- Q:when ferrous sulfate is poured into an aluminium can, holes appear in the can. Why?

- aluminum reacts via a redox reaction with iron(II): 3 Fe2+(aq) + 2 Al(s) --- 3 Fe(s) + 2 Al3+(aq)

- Q:Can aluminum coils be used in the production of heat sinks?

- Indeed, the utilization of aluminum coils is applicable in the manufacturing process of heat sinks. Aluminum, owing to its remarkable thermal conductivity and affordability, enjoys widespread usage as a material for heat sinks. These heat sinks are efficiently employed in the dissipation of heat emanated from electronic components like processors, power transistors, and LED lights. The coils can be fabricated into diverse forms and dimensions to fulfill particular heat dissipation prerequisites. Furthermore, aluminum possesses the advantages of being lightweight, resistant to corrosion, and readily accessible, rendering it an optimal selection for the production of heat sinks.

- Q:Can aluminum coils be used in marine or saltwater environments?

- Yes, aluminum coils can be used in marine or saltwater environments. Aluminum is highly resistant to corrosion, making it a suitable choice for applications in saltwater environments.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Customized Aluminum Profile for Closet Door

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20 m.t.

- Supply Capability:

- 2000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords