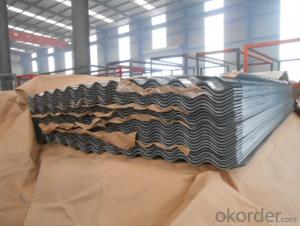

Corrugated Hot -Dip Galvanized Steel Sheet

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t

- Supply Capability:

- 1000 m.t/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Corrugated Hot Dipped Galvanized Steel Sheet

Description:

The corrugated sheet is a high strength and durable steel, mostly used for a architectural decoration. We have scores of corrugated sheets production lines of different types, producing profiled sheets of all kinds of types and colors. Since it adopts high strength steel sheet and the dimension is designed reasonably, the corrugated sheets are widely used on roofs and walls of various buildings, which can be easily installed, be flexible and changeable, unrestricted by no factor of the buildings.

Corrugated steel sheet is the colored steel plate which has been wave formed with the cold rolling treatment, trough especial coated dispose, the color coated steel panel’s guaranty is 12-15 years.

Application:

It has been widely applied on civil construction like storerooms, special building roof and walls of wide-span steel structure building and so on.

With excellent cold bending molded manufacturability, good decoration effect, strong anti-corrosion ability, are also pollution-free and easily recycled. Accordingly, they can be used as final products and basic plates of color coated steel coils and widely applied in construction, home appliances, decoration

Pressing steel panel with the clear line, and many colors for choice, suitable for any different building style materials, achieving satisfy effects;

Product Specification:

Thickness tolerance: (+/-0.01mm)

Zinc coating: 50-180g/m2

Standard:jis g 3302, sgch

Package: 2- 3 ton/pallet

Specs: 0.14-0.8mm x 900mm x 2000mm

Width:700-1250mm( 750mm,900mm,1215mm,1250mm,1000mm the most common)

Surface:regular/mini/zero spangle, chromated, skin pass, dry etc.

Package:Standard seaworthy export packing: 3 layers of packing, inside is kraft paper,water plastic film is in the middle and outside GI steel ,sheet to be covered by steel strips with lock.

FAQ:

1.How many pieces for one package?

The pieces for one tone is decided by the thickness of the sheet, but we can make it according to your requirements in the reasonable range.

2. Do you have pallets for the package?

Yes, we must use pallets for the package in order to load.

3. Could you produce the sheets according to our design?

Yes, we can.

- Q:Are steel sheets resistant to corrosion?

- Yes, steel sheets are resistant to corrosion due to their high iron content, which forms a protective oxide layer on the surface, preventing rust and other forms of corrosion.

- Q:Are steel sheets resistant to electromagnetic interference?

- Yes, steel sheets are generally resistant to electromagnetic interference due to their high electrical conductivity and ability to block or absorb electromagnetic waves.

- Q:How do steel sheets perform in cryogenic environments?

- Steel sheets perform well in cryogenic environments. Cryogenic temperatures, typically below -150°C (-238°F), can cause materials to become brittle and lose their strength. However, steel is known for its excellent toughness and can withstand low temperatures without significant degradation. Steel sheets are commonly used in cryogenic applications due to their ability to maintain structural integrity and resist fracture. They exhibit good thermal conductivity, which allows them to effectively transfer heat from the environment and prevent cold spots that could compromise the material's strength. Furthermore, steel's low coefficient of thermal expansion minimizes the risk of dimensional changes caused by extreme temperature variations. This property is crucial in cryogenic environments where precision and stability are required. Additionally, steel resists embrittlement, a phenomenon that affects certain materials when exposed to cryogenic temperatures for extended periods. Some materials become more susceptible to fracture due to the diffusion of hydrogen or other gases into their lattice structure. Steel, however, has a high resistance to embrittlement, making it a reliable choice for cryogenic applications. In summary, steel sheets perform admirably in cryogenic environments. They maintain their structural integrity, resist embrittlement, and minimize dimensional changes, making them a suitable material for various applications in industries such as aerospace, energy, and research.

- Q:Can steel sheets be used for heat exchangers?

- Yes, steel sheets can be used for heat exchangers. Steel is a commonly used material for heat exchangers due to its high thermal conductivity and durability. It can effectively transfer heat between fluids, making it suitable for various industrial applications.

- Q:Are the steel sheets suitable for HVAC ductwork?

- Indeed, steel sheets prove to be fitting for HVAC ductwork. Steel, being a robust and enduring substance, has the capability to endure the customary pressure and temperature fluctuations found in HVAC systems. Moreover, it possesses remarkable fire resistance qualities and is impervious to corrosion, making it an optimal choice for ductwork purposes. Furthermore, steel sheets can be effortlessly manipulated and molded into diverse forms and sizes to accommodate specific ductwork necessities. Consequently, steel sheets emerge as a dependable and frequently employed material in the construction of HVAC ductwork.

- Q:Can steel sheets be laminated with other materials?

- Yes, steel sheets can be laminated with other materials. Lamination is a process of bonding two or more materials together to create a composite material with enhanced properties. In the case of steel sheets, they can be laminated with other materials such as plastics, polymers, wood, or even other metals. This process is commonly used to improve the strength, durability, corrosion resistance, or aesthetic appearance of steel sheets. Laminated steel sheets can be found in various industries, including automotive, construction, aerospace, and furniture manufacturing.

- Q:Can steel sheets withstand extreme weather conditions?

- Yes, steel sheets are designed to withstand extreme weather conditions. Steel is known for its strength and durability, making it an ideal material for withstanding harsh weather elements such as high winds, heavy rain, snow, and extreme temperatures. Steel sheets are often used in construction, roofing, and outdoor applications where they are exposed to various weather conditions. Additionally, steel sheets can be coated with protective layers such as galvanized or painted finishes, which further enhance their resistance to corrosion and weathering. Overall, steel sheets are highly reliable and can endure extreme weather conditions with minimal damage or deterioration.

- Q:How do steel sheets perform in harsh chemical environments?

- Steel sheets generally perform well in harsh chemical environments due to their inherent strength and resistance to corrosion. However, the specific performance of steel sheets in such environments depends on factors such as the type and concentration of chemicals, temperature, and exposure duration. In some cases, additional protective coatings or treatments may be necessary to enhance the steel sheets' resistance to chemical corrosion.

- Q:Are the steel sheets suitable for HVAC applications?

- Yes, steel sheets are suitable for HVAC applications. Steel is a strong and durable material that can withstand high temperatures and mechanical stress, making it ideal for use in heating, ventilation, and air conditioning systems. Steel sheets are commonly used to fabricate HVAC components such as ducts, plenums, and air handling units. They offer excellent corrosion resistance, which is essential for maintaining the quality and longevity of HVAC systems. Steel sheets can be easily formed and welded, allowing for customization and efficient installation. Overall, the use of steel sheets in HVAC applications ensures reliable performance and longevity of the system.

- Q:Can steel sheets be used for automotive manufacturing?

- Certainly, steel sheets have the ability to be employed in automotive production. The automotive sector extensively utilizes steel due to its robustness, longevity, and cost efficiency. Steel sheets find common application in diverse automotive constituents like body panels, chassis, frames, and structural reinforcements. They offer the essential strength and stiffness necessary to ensure the safety and functionality of vehicles. Furthermore, steel sheets can be effortlessly shaped and molded into various forms, rendering them appropriate for intricate automotive designs. Additionally, steel is easily obtainable, hence making it a favored option for automotive manufacturers.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Corrugated Hot -Dip Galvanized Steel Sheet

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t

- Supply Capability:

- 1000 m.t/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords