Corrosion Resistant and Fire Resistant FRP Grating with Modern Shape

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m²

- Supply Capability:

- 500000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Introduction

FRP Molded Grating is a structural panel which uses high-strength E-Glass roving as reinforcing material, thermosetting resin as matrix and then casted and formed in a special metal mold. It provides properties of light weight, high strength, corrosion resistance, fire resistance and anti-skid. FRP Molded Grating is widely used in oil industry, power engineering, water & waste water treatment, ocean survey as working floor, stair tread, trench cover, etc. and is an ideal loading frame for corrosion circumstances.

Feature

l Corrosion Resistance

l Fire Resistance

l Light Weight & High Strength

l Safety & Anti-slip

l Electrical Insulating

l Aging Resistance

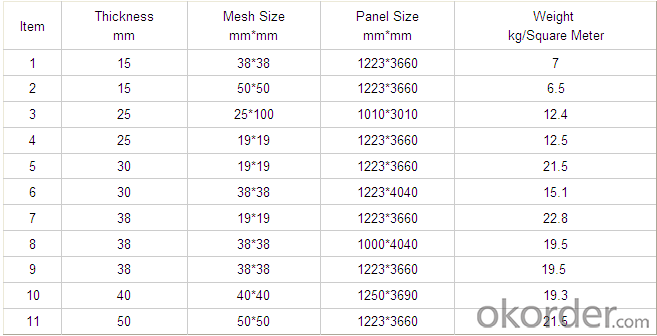

Specification

Advantage

1) coated with prevent aging layer

2) excellent insulating performance

3) no maintenance

4) high strength

5) long service life

6) easy installation

Application

l Power plants, substation equipment enclosures, antimagnetic, anti-static,to prevent small animals into the equipment failure, as there is electricity facilities and without power interval intervals.

l In high voltage electrical equipment for power line work, in order to prevent workers go wrong location, charged interval or near electrically charged equipment to dangerous distance.

l Pool railings in sewage treatment industry

l Corrosive chemical industry equipment around the fence

l All kinds of building maintenance section

FAQ

1. How about the documents after shipment?

After shipment, we ll send all original documents to you by DHL, including Packing List.Commercial Invoice, B/L, and other certificates as required by clients.

2. How long is the delivery time?

Usually it takes 10-25days after receipt of the deposits or L/C, and it also depends on the quantity of your order.

3. How's the payment?

Telegraphic Transfer(T/T) or Letter of Credit(L/C)

4. Do You Arrange Shipment?

Yes, dear esteemed customers, for FOB or CIF price, we will arrange shipment for you. For EXW price, clients need to arrange shipment by themselves or their agents.

5. How is the package?

Usually, we arrange the standard out-package for exporting.

PROCESS

FACTORY

- Q:Can FRP pultrusion profiles be customized or tailored to specific project requirements?

- Yes, FRP (Fiber Reinforced Polymer) pultrusion profiles can be customized or tailored to specific project requirements. Pultrusion is a manufacturing process that allows for the creation of continuous fiber-reinforced composite profiles with a high level of design flexibility. The specific requirements of a project, such as dimensions, shapes, and mechanical properties, can be accommodated by adjusting the design and manufacturing parameters. The customization process begins with understanding the project's needs and specifications. This includes determining the desired profile dimensions, cross-sectional shape, and mechanical properties such as strength, stiffness, and durability. Based on these requirements, engineers and manufacturers can develop a tailored solution. The customization of FRP pultrusion profiles can be achieved through various means. Firstly, the choice of reinforcement materials, such as fiberglass, carbon fiber, or aramid fiber, can be selected based on the desired mechanical characteristics. The orientation and volume fraction of the fibers can also be adjusted to optimize the strength and stiffness of the profile. Additionally, the resin matrix used in the pultrusion process can be customized to enhance specific properties, such as fire resistance, chemical resistance, or UV resistance. Various resin systems, including polyester, vinyl ester, or epoxy, can be utilized to meet the project's requirements. Furthermore, the pultrusion process allows for the incorporation of additional features during manufacturing. This includes adding inserts, fastener holes, grooves, or other structural details to the profile. These modifications can be tailored to the specific project requirements, ensuring compatibility with the overall design and assembly. Overall, FRP pultrusion profiles offer a high degree of customization and tailoring to meet specific project requirements. This versatility makes them a popular choice in various industries, including construction, infrastructure, aerospace, and automotive, where lightweight, durable, and corrosion-resistant materials are needed.

- Q:Can FRP pultrusion profiles be used for structural applications?

- Certainly, FRP pultrusion profiles can be utilized for structural purposes. The process of pultrusion involves pulling fiber reinforcements through a resin bath and a heated die to cure the resin, resulting in robust, lightweight, and corrosion-resistant profiles with exceptional mechanical properties. The high strength-to-weight ratio of FRP pultrusion profiles makes them widely employed in different structural applications. These profiles can be engineered to possess specific load-bearing capacities, stiffness, and durability, making them suitable for a wide range of structural requirements. FRP pultrusion profiles find common use in various structural applications such as bridges, walkways, platforms, handrails, supports, beams, columns, and reinforcements in concrete structures. They are particularly advantageous in situations where traditional materials like steel or wood are unsuitable due to concerns regarding corrosion, electrical conductivity, or weight. The benefits of FRP pultrusion profiles are numerous. They are lightweight, making them easy to handle and transport. Furthermore, they exhibit resistance to corrosion, chemicals, and UV radiation, ensuring long-term durability even in harsh environments. Additionally, they possess excellent dimensional stability, remaining unaffected by warping, twisting, or shrinking over time. To summarize, FRP pultrusion profiles are highly suitable for structural applications owing to their strength, lightweight nature, corrosion resistance, and durability. They provide a cost-effective alternative to traditional materials while delivering superior performance in various structural projects.

- Q:Can FRP pultrusion profiles be used in the production of electrical busbars?

- FRP pultrusion profiles possess exceptional electrical insulation properties, a high strength-to-weight ratio, and resistance to corrosion, making them suitable for the manufacturing of electrical busbars. These profiles excel in electrical insulation, reducing the likelihood of electrical shock and short circuits when compared to conventional metal busbars. Furthermore, their superior strength-to-weight ratio allows for lightweight busbars capable of handling substantial electrical currents without compromising structural integrity. In addition, FRP pultrusion profiles demonstrate exceptional resistance to corrosion and chemicals, making them an ideal choice for harsh environments like chemical plants or outdoor installations. They remain free from rust and degradation, ensuring the longevity and reliability of the electrical busbars. Ultimately, FRP pultrusion profiles offer a cost-effective and efficient solution for the production of electrical busbars, providing improved electrical insulation, strength, and corrosion resistance compared to traditional metal alternatives.

- Q:How do FRP pultrusion profiles perform in electrical grounding systems?

- FRP pultrusion profiles perform well in electrical grounding systems due to their non-conductive properties. Unlike metal profiles, FRP profiles do not carry electrical current, making them a safe and effective choice for electrical grounding applications. Additionally, FRP profiles are corrosion-resistant, durable, and lightweight, making them a reliable and long-lasting option for grounding systems.

- Q:How do FRP pultrusion profiles perform in seismic zones?

- FRP pultrusion profiles are highly suitable for use in seismic zones due to their inherent properties and characteristics. One of the key advantages of FRP pultrusions is their excellent strength-to-weight ratio, which allows them to efficiently withstand seismic forces without adding significant weight to the structure. In seismic zones, buildings and structures are subjected to intense ground motions during an earthquake. FRP pultrusion profiles possess high stiffness and strength, enabling them to effectively resist the lateral forces generated by seismic activity. These profiles have a high modulus of elasticity, which allows them to maintain their shape and structural integrity even under extreme seismic loads. Moreover, FRP pultrusions exhibit excellent corrosion resistance, making them highly durable in seismic zones. Unlike traditional materials such as steel or concrete, FRP profiles do not corrode when exposed to moisture, chemicals, or salts, which are commonly found in seismic regions. This corrosion resistance ensures the long-term performance and structural integrity of FRP pultrusion profiles, even in harsh environmental conditions. Another advantage of FRP pultrusions in seismic zones is their flexibility and ability to dampen vibrations. During an earthquake, the ground motions cause structures to vibrate. The inherent damping properties of FRP materials help absorb and dissipate these vibrations, reducing the potential for structural damage. Additionally, FRP pultrusion profiles can be designed and manufactured to meet specific seismic requirements and codes. They can be reinforced with additional layers or designed with specific geometries to enhance their seismic performance, ensuring that they meet the necessary safety standards in seismic zones. Overall, FRP pultrusion profiles offer numerous benefits for use in seismic zones. Their high strength-to-weight ratio, corrosion resistance, damping properties, and design flexibility make them an excellent choice for constructing seismic-resistant structures while ensuring durability and safety.

- Q:What is the torsional strength of FRP pultrusion profiles?

- Various factors, such as the type and arrangement of fibers, resin matrix, manufacturing process, and overall profile design, determine the torsional strength of FRP pultrusion profiles. Typically, FRP pultrusion profiles are designed to possess a high torsional strength, thanks to the inherent properties of the composite materials utilized. The specific application and desired performance requirements can result in variations in the torsional strength of FRP pultrusion profiles. Manufacturers frequently conduct extensive testing to ascertain the torsional strength of their profiles and provide customers with relevant data. In comparison to conventional materials like steel or aluminum, FRP pultrusion profiles are renowned for their exceptional torsional strength. The combination of high-strength fibers and a robust resin matrix enables FRP profiles to endure substantial torsional forces without experiencing permanent deformation or failure. It is worth noting that the torsional strength of FRP pultrusion profiles can be tailored to meet the precise demands of a project. Manufacturers can optimize the torsional strength by adjusting the fiber type, fiber orientation, resin system, and profile geometry. This ensures that the profiles can withstand the anticipated loads and operational conditions. In conclusion, the torsional strength of FRP pultrusion profiles is typically high due to the unique properties of the composite materials used. Furthermore, it can be further customized to satisfy specific application requirements.

- Q:How is FRP pultrusion different from other manufacturing processes?

- FRP pultrusion is different from other manufacturing processes in its unique method of producing fiber-reinforced polymer (FRP) profiles. Unlike traditional processes like extrusion or injection molding, pultrusion involves pulling continuous fibers through a resin bath and then into a heated die, where they are cured and shaped into the desired profile. This continuous and automated process allows for the production of strong, lightweight, and corrosion-resistant FRP profiles with consistent mechanical properties. Additionally, pultrusion enables the incorporation of various fiber orientations and resin systems, making it highly versatile for customized applications.

- Q:Are FRP pultrusion profiles resistant to high-pressure gas?

- Yes, FRP pultrusion profiles are generally resistant to high-pressure gas due to their excellent corrosion resistance and structural integrity. The inherent properties of FRP, such as high strength-to-weight ratio and non-reactivity to gases, make them suitable for various applications involving high-pressure gas environments. However, it is recommended to consult with the manufacturer or engineer to ensure specific requirements are met for the intended application.

- Q:Can FRP pultrusion profiles be used in aerospace applications?

- Yes, FRP (Fiber Reinforced Plastic) pultrusion profiles can be used in aerospace applications. FRP materials have several advantages that make them suitable for aerospace use. Firstly, they have excellent strength-to-weight ratios, which is crucial in the aerospace industry to reduce weight and enhance fuel efficiency. Secondly, FRP materials exhibit high corrosion resistance, making them suitable for prolonged exposure to harsh environments, such as high altitude and extreme temperatures. Additionally, FRP pultrusion profiles offer design flexibility, allowing for complex shapes and geometries to be manufactured. This flexibility enables aerospace engineers to tailor the profiles to specific requirements and optimize performance. Furthermore, FRP materials have low thermal conductivity, which helps in insulation applications and reducing heat transfer. Lastly, FRP pultrusion profiles have demonstrated good fatigue resistance, which is essential for aerospace applications subjected to cyclic loading. Overall, these properties make FRP pultrusion profiles a viable choice for various aerospace components, including structural members, interior parts, and electrical enclosures.

- Q:Can FRP pultrusion profiles be used in walkway systems?

- Walkway systems can indeed utilize FRP (Fiber Reinforced Polymer) pultrusion profiles. These profiles are renowned for their impressive strength-to-weight ratio, resistance to corrosion, and durability, which makes them an excellent option for various applications, including walkway systems. Due to the lightweight nature of FRP pultrusion profiles, they are easy to handle and install, which ultimately reduces construction time and cost. Moreover, their corrosion resistance ensures that they can endure harsh environmental conditions, such as exposure to moisture, chemicals, and UV radiation, without deteriorating or requiring frequent maintenance. FRP pultrusion profiles can be tailored to meet specific design requirements, enabling the creation of walkway systems with diverse shapes, sizes, and load-bearing capacities. These profiles can be manufactured with anti-slip surfaces or integrated with other safety features to enhance traction and prevent accidents on the walkways. Furthermore, FRP pultrusion profiles possess excellent electrical insulation properties, making them suitable for walkway systems in areas where minimizing electrical conductivity is necessary, such as power plants or electrical substations. All in all, the distinctive properties of FRP pultrusion profiles make them a dependable and versatile material choice for walkway systems. They offer long-lasting performance, low maintenance requirements, and enhanced safety.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Corrosion Resistant and Fire Resistant FRP Grating with Modern Shape

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m²

- Supply Capability:

- 500000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords