Colored borosilicate glass tube for Mouth blowing glasswares

- Loading Port:

- XINGANG

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2000 kg

- Supply Capability:

- 20000000000 kg/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Item specifice

1. Description:

Using the latest technology, our coloured borosilicate glass tubing3.3 correspond to the internationally acknowledged borosilicate glass type 3.3(DIN ISO 3585).

All stages of production are strictly controlled and backed up by a complete quality control system according to ISO9002.

Till now we can supply eleven kind of colors: transparent black borosil glass tubing, teal borosilicate glass tubing, dark blue borosilicate glass tubing, dark amber borosilicate glass tubing, pink borosilicate glass tubing, opaque black borosilicate glass tubing, yellow borosilicate glass tubing, red borosilicate glass tubing, green borosilicate glass tubing etc

2. Technical Description

Regular Specification: 25*4mm, 32*3.2mm, 32*4mm, 38*3.2mm, 38*4.0mm, 44*4.0mm, 51*4.0mm, 51*4.8mm etc.

Color high borosilicate glass is a kind of hard glass, Coefficient of thermal expansion is 3.30.1*10-6/K.

It is a kind of special glass material which is low inflation, high temperature resistant, high strength, high hardness, high light transmittance and high chemical stability. Because of its molecular structure is more closely, so even very thin is still strong and durable, The glass is colored at temperatures above 1600 degrees, so color is bright such as crystal clear, the color is never changed. In the production process, the technician keeps spinning the embryo and pulling it into a grain written. So observed in the sun, there are some textures, this is the normal glass process phenomenon.

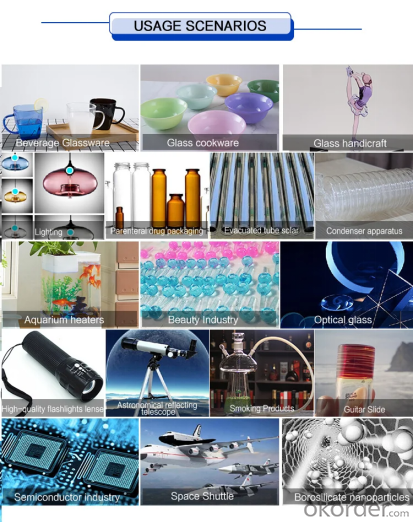

3. Widely usages of borosilicate glass tube

1. Kitchenware

2. Lighting Decorations

3. Chemical equipment

4. Solar Vaccum Tubes

5. Glass Arts & Crafts

6. Glass Smoking Pipes

7. Medical Pacakaging

8. Laboratory Instruments

4. Advantages

1. High quality,competitive price and elegant appearance

2. Accurate dimension according to customs' request

3. Long time to use

Customize specifications according to your demands:

O. D from 4mm~315mm,

W.T from 0.8mm~9mm,

5. Business Terms

Delivery time: Within 20days after received the advance payment.

Payment: 30%-50% TT in advance and balance against copy of BL.

Transport: By ship or express

Colors available: opaque black, opaque white, pink,purple, green,yellow, amber,dark blue, light blue, transparent blac

Usage:

6.

Process:

7. Packing and Shipping:

All the glass will pack in cartons, and load in container strong firmly, to make sure safety delivery.

8. Test Report

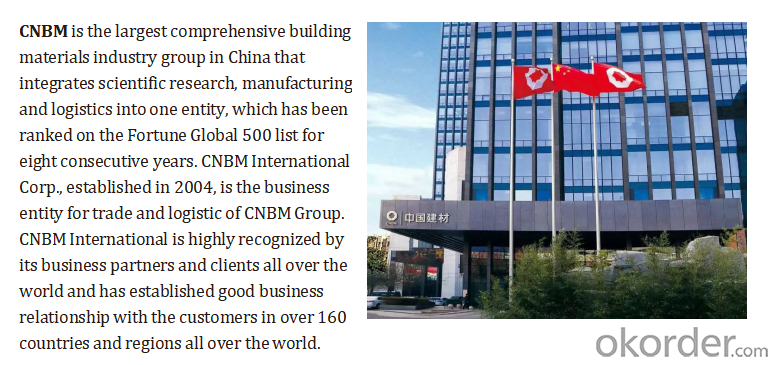

9. Company Brief:

10. FAQ:

Q1: Are you factory or trading company?

A: We are manufacturer in Hebei Province near Beijing,and we also have trading office in Beijing.

Q2: Can support OEM&ODM order?

A: Yes,we have rich experience in OEM&ODM production, can meet your personalized needs.

Q4: Can you do the designs for us?

A: Yes.We have a professional team having much experience in designing and manufacturing.Just let us know your ideas,we will draw the finished files for your confirmation.

Q5: What format of the file do you need if I want my own design?

A: You can provide JPG,Al,or PDF etc,Our professional designer will draw art work for mould or printing screen for you.

Q6: How can I get some samples?

A: Sure,we usually provide existing samples for free.But a little sample charge for custom designs,Sample charge is refundable when order is up to certain quantity.

- Q:What is the raw material of glass made of?

- The glass raw materials used for the natural ore, so the manufacture of glass, first of all to all kinds of ore crushing, processing into powder, then according to the glass component, made with the material into the glass melting furnace for melting glass forming liquid. Qualified glass flows through the feed tank and flows out of the feed port to form the stock. The temperature of the stock is 1150~1170 degrees centigrade and the alkali free glass is 1200~1220 degrees centigrade. The material shares every minute near '200 times cut into ball billet. The billet passes through the chute, the ball distributor and the ball plate, and then rolls into different funnels respectively, then falls into a groove formed by three rollers with the same rotating direction. When the ball is rotated on the roller and its surface tension, the ball glass is formed gradually. Its diameter is determined by the thickness, velocity, and shear velocity of the glass stream.

- Q:Glass fiber reinforced plastic (FRP) is a new type of composite material. What is the raw material?

- Building materials market will be on sale. Glass fiber reinforced plastic (FRP) is a kind of composite material made of glass fiber and one or several thermosetting or thermoplastic resins, such as phenolic resin, epoxy resin, polyester resin, polyimide resin, etc.. Glass fiber reinforced plastic is a new type of composite material developed in early twentieth Century. It has many advantages, such as light weight, high strength, anticorrosion, heat preservation, insulation, sound insulation and so on. The first composite was fiberglass, in fact, it had nothing to do with steel. There is no iron in glass fiber, nor is it a composite of glass and steel.

- Q:What is the difference between FRP and carbon fiber?

- Glass fiber (formerly known as English: glass fiber or fiberglass) is a kind of excellent inorganic non-metallic materials, variety, has the advantages of good insulation, strong heat resistance, good corrosion resistance, high mechanical strength, but the disadvantage is brittle, poor wear resistance. It is a glass ball or waste glass as raw materials by high temperature melting, wire drawing, winding and weaving process for production, the filament diameter of several microns to twenty micron, the equivalent of a hair 1/20-1/5, each bundle of fibers by hundreds or even thousands of root root filaments. Glass fiber is usually used as reinforcing material in composite materials, electrical insulation materials and insulation materials, circuit boards and other fields of national economy.

- Q:Why are most of the chemical instruments made from glass?

- Of course, the glass is colorless and transparent is also very important, the front of some people said that the glass is cheap, I would like to deny, in fact, this glass is not often in general glass, high temperature, the cost is much higher than that

- Q:What are the raw materials for producing edible glass bottles (such as pickles bottles, fermented beancurd bottles, etc.), and glass is the kind of glass material?

- The production of glass bottles industry, its raw materials are stone powder, quartz sand, soda ash, waste glass and coalA variety of materials used in the preparation of glass batch, collectively referred to as glass raw materials. In general by the 7-12 component, the main material is 4-6, such as quartz sand, limestone, feldspar, sodium carbonate, boric acid, lead compounds, barium compounds, according to the introduction of oxides in the glass structure effect, can be divided into glass forming oxide materials, intermediate oxide materials, network oxides materials, according to the the properties of oxide, can be divided into raw material, acid alkali metal oxide oxide materials. The glass batch is obtained some necessary properties and accelerate the melting process of raw materials, although less, but it is very important that these materials as clarifying agent, fluxing agent, coloring agent, bleaching agent, emulsifying agent, oxidizing agent and reducing agent etc..The same raw materials, different formulations, the same raw materials, different habitats and different indicators, will affect product quality and production costs. In the case of a small gap in raw material costs, the glass bottles produced are very different from each other in the comparison of small samples, and the difference can only be seen in batch production.

- Q:What are the raw materials for making glass?

- The main raw material for making glass is sand, its main component is silica, which is commonly called quartz.

- Q:The shell of glass steel electric cars will not be on the poor out of the glass Sizha?

- There are 2 kinds of process for making automobile shell with glass fiber reinforced plastic, 1. hand paste forming process and 2. pressing processThe choice of raw materials is reasonable, according to the operating procedures, the product is not defective, will not appear exposed fiber, it will not cause skin itchingA small number of unscrupulous manufacturers, technical level is low, Jerry built products must be betterYou can spray a layer of resin or a layer of dry adhesive tape on the exposed surface of the fiber when you encounter inferior products

- Q:What materials are needed for the production of glass bottles and what are their proportions?

- There are many kinds of glass, different kinds, different uses, and different ingredients.

- Q:What is resin glass fiber reinforced plastic?

- Raw materials: glass fiber / or its products + resin + (filler) + other additives;Process: hand / pull / winding / molding / injection molding etc..Resin is only a raw material for the production of glass fiber reinforced plastic! That's not what you call it.

- Q:What are the main raw materials for making ceramics, glass and cement?

- The main raw materials for glass production are quartz, feldspar (potassium feldspar, albite) and soda ash

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Colored borosilicate glass tube for Mouth blowing glasswares

- Loading Port:

- XINGANG

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2000 kg

- Supply Capability:

- 20000000000 kg/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches