Ceramic fiber insulation wool rope

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 m.t.

- Supply Capability:

- 100 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Quick Details

| Application: | Refractory | Grade: | ST (Standard) | Working Temperature: | 1050C |

| Place of Origin: | China (Mainland) | Brand Name: | SUNTHERM | Model Number: | SS wire reinforced |

| Certificate: | BV,SGS,CE,ROHS,ISO9001:2000 | Sample: | Available | MDS Availabel: | Yes |

Packaging & Delivery

| Packaging Detail: | Woven bag , carton or as your demand to custom |

| Delivery Detail: | Within 15 days after received the deposit. |

Specifications

Ceramic fiber textile

AL2O3:45%

Fiber diameter:3-5um

Temperature:1050C ISO9000 certificate

ceramic fiber rope includes square braided rope, round braided rope and twisted rope. All are made from high quality ceramic fiber material. The rope is reinforced with fiberglass filament, or alloy steel wire. Fiberglass filament reinforced rope can work in the temperature below 650C with electric insulating property, while alloy steel wire can work in the temperature 1100C with higher strength. Ceramic fiber textiles (cloth, tape and rope) contain a certain amount of binder material which is normally burned at lower temperature and does not affect the insulation property .The three different styles are designed to fit different application needs: twisted rope is a soft rope, while square and round braid are more dense and solid.

Product information

Item | Ceramic fiber rope |

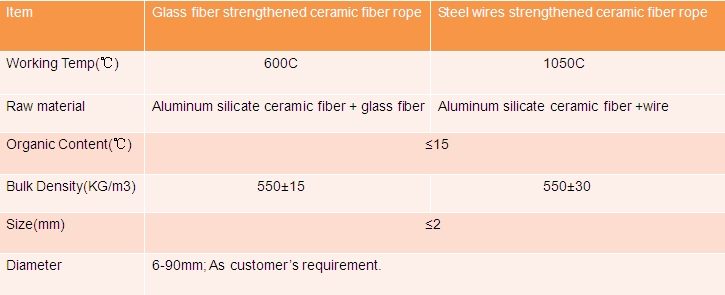

Type | Glass fiber strengthened ceramic fiber rope Steel wires strengthen ceramic fiber rope |

Applications | • High temperature static seal e.g. door joint or gaskets for flanges • Fire protection e.g. fires proof curtain against welding spark. • The protection of cable, fuel tubes etc • Fireproof twine, wrap, cover etc • Pipe or round duct insulation lagging • Asbestos substitute |

Features | •Excellent high temperature stability • Excellent tensile strength • Excellent thermal electrical insulation • Excellent chemical stability resistance • Low thermal conductivity. |

Packing | In plastic bags, in cartons or according customers requirement. |

Payment Terms | L/C, D/A, D/P, T/T, Western Union, MoneyGram, Cash. |

Delivery Time | Within 15 days after received the deposit. |

Certificate | ISO9001-2000, ISO14001-2000, CE ,SASO,SGS . |

Technical data

- Q:Can glass fiber textile be used in geotextile applications?

- Yes, glass fiber textile can be used in geotextile applications. Glass fiber textiles have high tensile strength, durability, and resistance to chemicals and environmental factors, making them suitable for reinforcement and stabilization purposes in geotechnical engineering projects such as road construction, slope stabilization, and erosion control.

- Q:What are the different additives used in glass fiber textiles?

- There are several additives that are commonly used in glass fiber textiles to enhance their performance and functionality. These additives can be classified into various categories based on their intended purpose. One category of additives used in glass fiber textiles is sizing agents. Sizing agents are applied to the glass fibers during the manufacturing process to improve their handling characteristics and adhesion to other materials. They also help to reduce static electricity and improve the wetting properties of the fibers, ensuring better impregnation of resins or other binding materials. Another category of additives is flame retardants. Flame retardants are added to glass fiber textiles to enhance their resistance to fire and reduce the risk of ignition and spread of flames. These additives can help to improve the safety of the textiles in various applications, such as in building materials, automotive interiors, and protective clothing. UV stabilizers are also commonly used additives in glass fiber textiles. These additives help to protect the textiles from degradation caused by exposure to ultraviolet (UV) radiation from the sun. UV stabilizers can extend the lifespan of the textiles and maintain their color and physical properties, making them suitable for outdoor applications. Antistatic agents are additives used to reduce or eliminate static electricity in glass fiber textiles. Static electricity can cause various issues, such as attracting dust and dirt, interfering with electronic equipment, and posing a risk of electrostatic discharge. Antistatic agents help to dissipate static charges and improve the conductivity of the textiles, ensuring a static-free environment. Furthermore, lubricants can be used as additives in glass fiber textiles to improve their processing and handling properties. These lubricants can reduce friction and facilitate the movement of fibers during the weaving or knitting process, making it easier to produce high-quality textiles. It is worth mentioning that the specific additives used in glass fiber textiles can vary depending on the intended application and the desired properties of the final product. Manufacturers carefully select the appropriate additives to meet the specific requirements and performance standards of different industries and applications.

- Q:How are glass fiber textiles manufactured?

- Glass fiber textiles are manufactured through a process called fiberglass production. It involves melting glass in a furnace at high temperatures and then drawing it into thin strands or filaments. These filaments are then coated with a chemical binder to bind them together and form a continuous fiber. The fibers are then spun into yarns or woven into fabrics, depending on the intended application.

- Q:Can glass fiber textile be used in agricultural applications?

- Glass fiber textiles have the potential to be utilized in agricultural applications. Renowned for their robustness, endurance, and ability to withstand diverse environmental conditions, glass fiber textiles are well-suited for implementation in the agricultural sector. They can serve as a reinforcement material for agricultural structures, such as greenhouses, providing exceptional insulation and resistance to weather conditions. Furthermore, glass fiber textiles can be integrated into the production of agricultural machinery and equipment, presenting components that are lightweight yet sturdy. In addition, they can be employed as filtration material for purifying water or air in agricultural systems. Overall, glass fiber textiles have established themselves as a dependable and adaptable choice for a wide range of agricultural uses.

- Q:How do glass fiber textiles affect the breathability of fabrics?

- Glass fiber textiles can significantly affect the breathability of fabrics. When incorporated into fabrics, glass fibers tend to reduce the breathability due to their non-porous nature. Glass fibers are tightly woven or knitted, resulting in a dense fabric structure that limits air circulation. This restricts the movement of air and moisture through the fabric, making it less breathable. Additionally, glass fiber textiles often have a smooth surface, which further hampers breathability. This smooth surface prevents air from easily passing through the fabric, creating a barrier that reduces ventilation and airflow. However, it is important to note that the impact on breathability varies depending on the specific composition and construction of the fabric. Some fabrics may have a lower concentration of glass fibers or different weaving techniques that allow for better air permeability. Manufacturers may also employ special treatments or finishes to enhance breathability in glass fiber fabrics. Overall, the presence of glass fiber textiles in fabrics can generally diminish breathability. This factor should be considered when selecting fabrics for applications where breathability is a crucial requirement, such as in sportswear, outdoor clothing, or bedding.

- Q:Can glass fiber textiles be used for reinforcement in plastics?

- Glass fiber textiles are capable of reinforcing plastics. When utilized as reinforcement in plastics, glass fibers exhibit strength and offer exceptional mechanical properties. They bolster the final plastic composite's strength, stiffness, and impact resistance. In industries like automotive, aerospace, construction, and consumer goods, glass fiber textiles are extensively employed to reinforce plastic parts and components. The amalgamation of glass fibers and plastics results in a composite material that is lightweight, long-lasting, and possesses remarkable tensile strength.

- Q:Can glass fiber textile be woven?

- Glass fiber textile can indeed be woven. These textiles are formed by spinning thin strands of glass into yarn and subsequently interlacing them to produce a fabric. This weaving technique resembles that of cotton or silk fabrics. Glass fiber textiles are renowned for their exceptional toughness and longevity, rendering them appropriate for a wide range of uses including insulation, reinforcement, and protective garments.

- Q:Can glass fiber textiles be used in printed circuit boards?

- Yes, glass fiber textiles can be used in printed circuit boards.

- Q:How is glass fiber textile used in the construction industry?

- Glass fiber textile is widely used in the construction industry for its strength and durability. It is commonly used as a reinforcement material in concrete, providing added strength and resistance to cracking. Glass fiber textile is also used as insulation material in buildings, helping to improve energy efficiency and reduce heat transfer. Additionally, it is used in the production of composite materials, such as fiberglass panels and sheets, which are used in various construction applications like roofing, walls, and flooring. Overall, glass fiber textile plays a crucial role in enhancing the structural integrity and performance of buildings in the construction industry.

- Q:Are glass fiber textiles resistant to discoloration in contact with sweat?

- Yes, glass fiber textiles are generally resistant to discoloration when in contact with sweat.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Ceramic fiber insulation wool rope

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 m.t.

- Supply Capability:

- 100 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords