Ceramic Fiber Blanket 1260 C 1400 C 1600 C

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 m.t.

- Supply Capability:

- 100 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Quick Details

| Grade: | HA (High Aluminum) | Application: | Refractory | Thickness: | 25 or 50 |

| Width: | 610 | Length: | 7200 | Chemical Composition: | Al2O3 |

| Ultimate Strength (≥ MPa): | 500 | Working Temperature: | 1260 | Fiber Diameter: | 0.005 |

| Shrinkage (1800 ℉, 3h): | 2 | Thermal Conductivity: | 60 | Density (kg/m³ ): | 128 |

| Model Number: | 1260 | Brand Name: | Place of Origin: | (Mainland) | |

| color: | white |

Packaging & Delivery

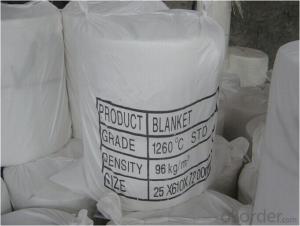

| Packaging Detail: | carton box |

| Delivery Detail: | 10 days |

Specifications

Ceramic fiber blanket 1260-1400-1600

High strength and low shrinkage

Good resiliency with low heat storage

Low thermal conduc

CMAX Ceramic fiber blanket

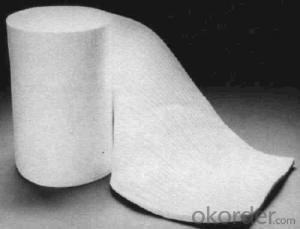

ceramic fire-resistant fiber blanket is a kind of continuous cotton tiled fiber blanket made by pure material melted in 2300 degrees of high temperature upon tossing and needling, which has high tensile strength, sound capability against chemical erosion and is smooth in surface. The fiber blanket is free from organic adhesive.

polycrystal fiber blanket is a kind of continuous cotton tiled fiber blanket made by chemical glue with more than 70% of alumina in content, which has very high thermal-resistant performance, tensile strength, sound capability against chemical erosion and is smooth in surface. Product Description

Ceramic fiber blanket

Ceramic fiber fiber blanket has excellent processing strength, can be processed into any shape. Ceramic fiber fiber blanket has various kinds of unit weight and specification, extreme high processing or construction strength, sound performance against high temperature, which can meet the requirements of various insulation applications between hot surfaces and cold surfaces in different kilns and furnaces.

Typical Applications

Kiln liner, boiler heat insulation, temperature control in heat treatment, top heat insulation for glass kiln

Furnace door sealing, inner flue liner, piping heat insulation, heat insulation parts inside transportation equipment

Fire-resistant home appliance heat sealing washer. Heat insulator for slowly stress releaing in heat treatment for outdoor welding seam

High temperature filtering media, heat insulation in nuclear power, heat insulation in vapor and thermal turbine.

Main performance | blanket | zirconic blanket | polycrystal blanket | |

Classified temperature | °C | 1260 | 1400 | 1600 |

Capacity (normal) | Kg/m³ | 64, 96, 128, 160 | 64,96, 128, 160 | 100,130 |

Unit weight | 128 Kg/m³ | 128 Kg/m³ | 130 Kg/m³ | |

In average temperature below | ||||

600°C | 0.12 | 0.12 | 0.1 | |

800°C | 0.16 | 0.16 | 0.15 | |

1000°C | 0.23 | 0.23 | 0.21 | |

Chemical composition | ||||

Al2O3 | % | 44 | 35 | 72 |

SiO2 | % | 56 | 50 | 28 |

ZrO2 | % | - | 15 | |

% | - | - |

Package: 15kg/carton

Fiber blanket size:7200×600×6,12.5,20,25,40,50mm

- Q:What are the ceramic fiber products?

- Ceramic fiber is produced by double needling technique and is widely used in high and low temperature environment. According to the different manufacturing technique used in market, ceramic fiber blanket is usually divided into two kinds. One is thread throwing blanket, and the other is injection fiber. 1. The diameter of the fiber filaments: Thread throwing fiber is much coarser. Thread throwing fiber is generally 3.0-5.0;micro;m; Injection fiber is generally 2.0-3.0;micro;ml. 2. Fiber length: Thread throwing fiber is much longer. Thread throwing fiber is generally 150-250mm. Injection fiber is generally 100-200mm. 3. Coefficient of thermal conductivity: Injection blanket is superior to thread throwing blanket because of its thin fiber. 4. Tensile and flexural strength: Thread throwing blanket is superior to injection blanket because of its coarse fiber. 5. Application of making ceramic fiber block: It is superior to injection blanket because the fiber of thread throwing blanket is much coarser and longer. Injection fiber blanket is easy to be broken and torn during the process of block production folding, while thread throwing fiber blanket can be tightly folded and cannot be easy to damage. The quality of the block will directly affect the quality of the lining. 6. The vertical layer spread application of large pieces of blankets such as heat recovery boiler: Thread throwing blanket has better tensile resistance and is more durable due to its coarse and long fiber filament, so thread throwing blanket is superior to injection blanket.

- Q:I have a 2.5 yr old male ferret and he's my little baby boy, I spoil him rotten lolAnyway I've noticed it appears he's lost a little weightHe doesn't seem to be eating properly but is drinking normally, active and alert and I haven't noticed any issues with his poopBut recently I have noticed he's getting into the habit of excessively chewing on his hammock and blanket, and I mean he spends nearly ALL of his time awake just chewing away but hardly ever eats! I'm very concerned and thinking of calling the vetAny other suggestions in the meantime? Thank you!

- Remington makes great hair straighteners that don't cost that muchI got mine for 20$ at Target and it works just as good as any chi i've ever hadActually, I've had about 5 Chi's and the LED light kept breaking.

- Q:inject something into the top? like what

- I live in San Antonio, so I feel the heat tooRadiant barrier, when correctly applied, reduce the heat gain inside the house from the outside sourcesThis means that your entire house stays cooler and is more efficient to keep coolThe Ducting simply moves the air around the house from the blower to the ventsThe ducting is somewhat insulated and as long as it is intact and does not have holes it is still functionalYou will save more money in the long run by the radiant barrier, it will help your A/C run more efficiently.

- Q:I thnk the above says almost all - What should I put under the floor to best reduce draught at not a high costThank you for your anticipated helpful advice.

- Microwaves heat food by emitting a strong radio signal within the cavity of the applianceThere is a lot of energy in that signal, and when it hits water, it causes it to vibrate, thus heating the food When it hits metal, it gets turned to electricity, just like it does when it hits the antenna on your carSince the foil isn't grounded, there is no place for that electricity to go, so it discharges as a sparkAnd it can't be good for your microwave oven, so stop doing that.

- Q:When I bought my house a few years ago, the home inspector recommended another layer of insulation in the attic floorMost of the attic floor is exposed joists (with batt insulation exposed) - there's only plywood flooring over a small portion of the attic.I need more storage so am planning to lay more plywood up thereWas wondering about adding additional insulationCan I just compress the batts that are already there and layer more on top? The existing insulation comes right to the top of the joists.Or do I need to somehow extend the joists vertically to make room for the new insulation?

- The answers you got about adding insulation to the roof instead of down on top of the existing insulation were stunningly stupid and ridiculousWhatever you do don't do something that crazy and wasteful! You're right on the money by saying it's not gonna be effective! It's downright insane! Think of the insulation on top of your ceiling as a blanketIf you need more insulation you pile on more blanketsPutting insulation up above the existing blanket of insulation onto the underside of the roof is absurdIf you're in bed and cold do you put another blanket up on the ceiling to get warm? Of course not! You pile on another blanket or 2 right on top of what's already there to warm you upI have put down plywood flooring in much of my attic just like what you're wanting to doThe best thing you can do is to beef up the joists that are already there to raise them above the existing insulation and add more insulation if you can create enough additional spaceWhatever you do don't just slap down plywood and compress the insulationThat greatly reduces it's R value and makes it much less effectiveThe plywood you put down will have next to no R value to speak of so don't kid yourself and think it's gonna help at allIn my home I actually put down 2 x 4's on top of the joists and I ran them at a 90 degree angle to the joistsThis was a lot easier than trying to run them directly on top of the joists and trying to attach them would have been a big painIt's a little harder to add additional insulation if you do it the way I did but it's not a big deal if you blow in more insulation on top of what's thereWhat you're wanting to do is a smart way to create additional storage and as a side benefit, if you do it right, will be a little more R value in your insulationGood luck and I hope this helps!

- Q:I am trying to find someone that can date fabric from the 1920quot;s

- A group that can help in the USA is the American Textile History MuseumIt is actually much harder to date fabric than clothing since styles change, but fabric has not changed that much and the same fabric comes back in production even as the styles changeExamination gets done by looking at the yarn types and constructionFor example, some yarns have not been made since the early 1900's, but others from that period are still madeIf it has synthetics, you know it is not old.

- Q:I'd really like to find a pattern for a guitar friendship braceletHowever, I can't really understand the arrows so maybe step by step directions? Please and thank you :)

- When insulation gets saturated, and you have no real way of circulating air around itThe insulation will hold water like a sponge, keeping the studs damp.you don't want thisFirst, determine if the insulation actually extends all the way to the floor(a lot of basement walls are only insulated four feet down from grade) If you can find an inconspicuous spot to open up a small section to inspect which is the case, you might be okay to let it dry out with dehumidifier and fansIf your insulation does in fact extend all the way to the bottom plate of the wall, You will be better off to remove the lower 12 inches of drywall and replace the wet insulation once the studs have dried(better still, leave the lower few inches without insulation if the wall is far enough below grade/ground level) Mold will grow and keep on growing if you don't get the situation under hand, and once the spores get airborne by the way of furnace fan, duct work, air-exchanger etc, your whole house and it's contents can become contaminatedThat's the worst case scenario, but I've seen it enough times to know you don't want itDo you have insurance? A friend of mine had to have their entire house and contents decontaminated following an issue like this that had gotten out of controltheir insurance covered it 100%, but the cost was over $200.000.00

- Q:I need to get into my house so that I can ask a question online.

- If your carbon fork has an aluminum steer tube it can in fact be bent backwards at the steer tube/fork crown junctionThe cracks in the frame are another indication of troubleSorry to say that both your fork and frame are finished and you should immediately stop riding that bikeYou could perhaps buy another frame and fork and transfer your components over to the new one but under no circumstances should you continue riding your bike as it is

- Q:what foods are high in fiber? why do you need to eat these foods to loose weight?

- I'm an Engineer in the U.SMy neighbor and good friend is a track inspector for another railroadSometimes I'll ride along with him in his HighRail on my days offHis is a Ford pick up truckThe HighRails are quick and easy to get on and off the tracks.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Ceramic Fiber Blanket 1260 C 1400 C 1600 C

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 m.t.

- Supply Capability:

- 100 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches