Carbon Steel Welding Wires Electrodes Carbon

- Loading Port:

- Qingdao

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 100 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

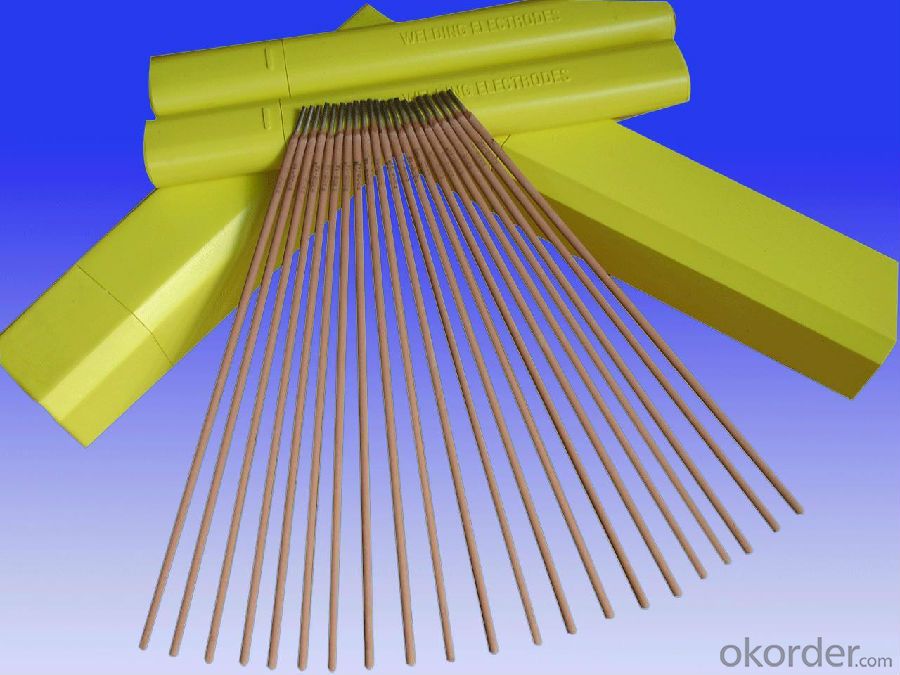

Structure of Carbon Steel Welding Wire Electrodes

1) Specially for Vertical-down welding

2) Perfect welding performance.

3)Operating current: 2.5MM:30-50,32.MM:70-100,4.0MM:90-140, 5.0MM: 150-200

4)Diameter:2.5mm-5.0mm

5)Material:Carbon Steel

6)Length:300-400mm

7)Delivery Time: 15-30 days after receiving L/C or pre-paid

Main Feature of Carbon Steel Welding Wire Electorde

Detail Package:All products will be standard export package, will be wooden boxes or bundled by steel strips, or as per customer's requirement

steel wire is a high cellulose potassium type welding rod for mild steel.

It is suitable for vertical -down welding and lap welding for sheet structures.

Such as smoke pipes, wind pipes ,oil tanks of teansformer, outside cover of vehicles.

FAQ

Why should you choose us?

Chose happens because of quality, then price, we can give you both. Additionally, we can also offer professional products inquiry, products knowledge train (for agents),

Quick goods delivery, our factories locate near the seaport, which is very convenient for transportation.

Datas Information of Carbon Steel Welding Wire Electorde

Chemical Composition of Deposited Metal(%)

| C | Mn | Si | S | p | Ni | Cr | Mo | V |

| ≤0.2 | ≤1.2 | ≤1.0 | ≤0.035 | ≤0.040 | ≤0.3 | ≤0.2 | ≤0.3 | less than 0.08 |

Pictures:

- Q:Anti loosening of stainless steel screw

- The first is the use of special material rebound properties, such as engineering resins, which have better rebound properties. Attach it to the stainless steel screw thread. Make it mechanically friction with nuts or material products. Generate vibration and absolute resistance. Completely solve the problem of screw loosening.

- Q:Can stainless steel wire be used for wire rope hoists?

- Yes, stainless steel wire can be used for wire rope hoists. Stainless steel has excellent corrosion resistance and high strength, making it suitable for various applications including wire rope hoists.

- Q:Is stainless steel wire resistant to corrosion?

- Indeed, stainless steel wire demonstrates resistance to corrosion. Comprised of iron, chromium, and additional elements, stainless steel generates a safeguarding layer on its surface. Known as the passive layer, this barrier prevents direct exposure of the wire to oxygen and moisture - the primary catalysts of corrosion. Consequently, stainless steel wire showcases remarkable durability against rust, tarnish, and other forms of corrosion. This exceptional characteristic renders stainless steel wire highly suitable and long-lasting for diverse applications, particularly in marine settings or for outdoor structures, where corrosion resistance is imperative.

- Q:What type of argon arc welding wire is used in 1Cr13 stainless steel?

- Argon arc welding generally uses H0Cr14 or H1Cr13. Sometimes austenitic steel wires are also selected to improve weldability.1Cr13+Q235B belongs to dissimilar steel welding, H0Cr20Ni10 welding wire is usually used.

- Q:Can stainless steel wire be used for fishing nets?

- Yes, stainless steel wire can be used for fishing nets. It is a durable and corrosion-resistant material that can withstand the harsh conditions of saltwater environments. Stainless steel wire provides strength and longevity to fishing nets, making it a suitable option for commercial and recreational fishing purposes.

- Q:What material of stainless steel screws is not easy to strip?

- Aiming at this problem to strip stainless steel screw screw. Not just as simple as the customer thinks, producing screws by changing the screws and wires of the material. Although this is a better solution. But we still have to analyze and analyze. To find out the reason for the screw tooth, then an antidote against the disease.

- Q:What are the different wire gauges available for stainless steel wire?

- Stainless steel wire gauges are available in a range of sizes to suit different applications and requirements. The most common wire gauges for stainless steel wire are typically measured in American Wire Gauge (AWG) or Standard Wire Gauge (SWG). AWG is the most widely used measurement system in the United States, where the wire diameter decreases as the gauge number increases. The available stainless steel wire gauges in AWG typically range from 10 to 38, with 10 being the thickest and 38 being the thinnest. These gauges are commonly used for various purposes such as electrical wiring, jewelry making, and industrial applications. On the other hand, SWG is a British measurement system that is also used in some parts of the world, including the United Kingdom. In SWG, the wire diameter increases as the gauge number increases. The available stainless steel wire gauges in SWG range from 1 to 46, with 1 being the thickest and 46 being the thinnest. These gauges are commonly used for different applications, including fencing, mesh manufacturing, and cable production. It's important to note that the specific wire gauges available for stainless steel wire may vary depending on the supplier or manufacturer. It is always recommended to check with the supplier or refer to the standardized wire gauge charts to determine the specific wire gauges available for stainless steel wire in order to select the appropriate gauge for your specific needs.

- Q:Is stainless steel wire resistant to abrasion?

- Yes, stainless steel wire is highly resistant to abrasion.

- Q:Can stainless steel wire be used for wire drawing?

- Yes, stainless steel wire can be used for wire drawing. It is commonly used for this purpose due to its excellent strength, durability, and resistance to corrosion.

- Q:What are the common uses of stainless steel wire in the mining industry?

- Due to its exceptional properties, stainless steel wire is extensively used in the mining industry for various applications. These include: 1. Screening and sieving: Stainless steel wire mesh is widely utilized in mining operations to separate minerals, rocks, and ores based on their particle size. Its high tensile strength and corrosion resistance enable it to withstand harsh conditions and abrasive materials found in mining environments. 2. Conveyor belts: Stainless steel wire ropes are commonly employed in mining conveyor belts to transport heavy loads over long distances. The excellent strength-to-weight ratio of stainless steel wire ropes ensures the durability and reliability of conveyor systems, even in demanding mining environments. 3. Reinforcement: Stainless steel wire is used to reinforce structures in mines, such as tunnels, shafts, and underground chambers. Its high tensile strength and corrosion resistance provide structural integrity, enhancing the stability and safety of mining operations. 4. Safety barriers and fencing: Stainless steel wire is frequently used in constructing safety barriers and fencing systems in mines. These barriers are designed to prevent access to hazardous areas, protect workers, and control the movement of vehicles and equipment within the mining site. The corrosion resistance and durability of stainless steel wire ensure long-lasting and effective safety measures. 5. Wire ropes for lifting and hoisting: Stainless steel wire ropes are employed for lifting and hoisting heavy loads in mining operations. These wire ropes are used in various applications, such as lifting equipment, cranes, and winches, to facilitate the safe and efficient movement of materials and machinery. 6. Filtration systems: Stainless steel wire mesh is utilized in mining filtration systems to remove impurities, solids, and contaminants from liquids and gases. The fine mesh structure of stainless steel wire allows for precise filtration, ensuring the purity and quality of mining processes and products. In conclusion, stainless steel wire is an indispensable material in the mining industry due to its exceptional strength, corrosion resistance, and versatility. Its diverse applications contribute to the efficiency, safety, and reliability of mining operations, enhancing productivity and minimizing downtime.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Carbon Steel Welding Wires Electrodes Carbon

- Loading Port:

- Qingdao

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 100 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords