Carbon Fiber Weaving Fabrics

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 5000KG kg

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product description

Among the existing structural materials, carbon fiber reinforced epoxy resin composites have the highest specific strength and modulus. In the areas of strict requirements on density, stiffness, weight, fatigue characteristics, high temperature and high chemical stability, CFRP have an outstanding advantage.

Main Features:

● Light weight

● Products high strength, high modulus

● Superior acid corrosion resistance

Product Specifications:

Density:100-400g/m2.

Item:1k,2k,3k,6k,12k.

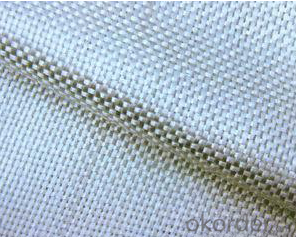

Weave:Plain,Twill,Satin,Multiaxial,UD

Packaging:

Each roll is wound onto a paper tube which has an inside diameter of 76mm and the mat roll has a diameter of 225mm. The roll is wrapped up with plastic film,and then packed in a cardboard box or wrapped up with kraft paper. The rolls can be horizontally placed. For transportation, the rolls can be loaded into a cantainer directly or on pallets.

Storage:

Unless otherwise specified, It should be stored in a dry, cool and rain-proof area. It is recommended that the room temperature and humidity should be always maintained at 15℃~35℃ and 35%~65% respectively.

- Q:How does fiberglass fabric perform in terms of sound absorption?

- Fiberglass fabric performs exceptionally well in terms of sound absorption. Its porous structure and high density make it an effective material for reducing echo and reverberation. It can effectively absorb a wide range of frequencies, making it suitable for various applications such as acoustic panels, soundproofing curtains, and insulation in buildings.

- Q:How is fiberglass fabric used in the medical industry?

- Due to its unique properties and characteristics, fiberglass fabric finds wide application in the medical industry. One primary use of fiberglass fabric in this industry is for the manufacturing of cast and splint materials. When a patient suffers from a fracture or broken bone, a combination of fiberglass fabric and resin material is used to create a cast or splint that offers support and immobilization to the affected area. The fabric is soaked in a resin solution and then applied to the patient's limb, where it solidifies and forms a rigid structure. The lightweight and durable nature of fiberglass fabric make it an ideal choice for these purposes as it provides the necessary rigidity and support while still allowing for mobility and comfort. Moreover, fiberglass fabric is also employed in the production of prosthetics and orthotics. Prosthetics are artificial limbs or body parts that replace missing or non-functional body parts, while orthotics are devices used to support, align, and improve the function of different body parts. Fiberglass fabric is often used as a reinforcement material in constructing these devices as it offers high strength and stability. The fabric is layered and bonded with other materials to create a sturdy and lightweight structure that can withstand daily wear and tear. Additionally, fiberglass fabric is utilized in manufacturing medical equipment such as surgical drapes and gowns. These fabrics are designed to act as a barrier against fluids and microorganisms, preventing contamination during surgical procedures. The impermeable nature of fiberglass fabric makes it an effective choice for these applications as it bars fluid penetration and maintains a sterile environment. In conclusion, fiberglass fabric plays a vital role in the medical industry by providing support, strength, and protection in various applications. Its versatility, durability, and ability to conform to different shapes and sizes make it an invaluable material for medical professionals in their efforts to provide optimal care and treatment to patients.

- Q:How does fiberglass fabric perform in moisture absorption?

- Fiberglass fabric is known for its excellent performance in moisture absorption. Due to its inherent characteristics and composition, fiberglass fabric has a very low moisture absorption rate. The fabric is made from fine fibers of glass that are woven together, creating a tight and dense structure. This structure prevents moisture from easily penetrating the fabric. Compared to other materials such as cotton or polyester, fiberglass fabric has a much lower moisture absorption rate. It does not readily soak up moisture like natural fibers, and it does not retain water for long periods of time. This is advantageous in applications where moisture resistance is important, such as in outdoor or marine environments. The low moisture absorption of fiberglass fabric also helps to maintain its dimensional stability. Even when exposed to high levels of humidity or moisture, the fabric does not swell or warp. This makes it a suitable choice for applications where maintaining shape and integrity is crucial, such as in composite materials or reinforcement applications. Furthermore, the low moisture absorption of fiberglass fabric also contributes to its resistance to mold and mildew growth. Since moisture is not easily absorbed by the fabric, it creates an unfavorable environment for the growth of these microorganisms. This property makes fiberglass fabric a popular choice in applications where moisture resistance and hygiene are important, such as in the manufacturing of medical equipment or food processing industry. In summary, fiberglass fabric performs exceptionally well in moisture absorption. Its low moisture absorption rate, dimensional stability, and resistance to mold and mildew growth make it a reliable choice in various industries and applications.

- Q:How does fiberglass fabric perform in terms of chemical stability?

- Fiberglass fabric demonstrates excellent chemical stability, making it highly resistant to various chemicals, acids, and alkalis. It does not degrade or react with most chemicals, ensuring its durability and longevity in harsh chemical environments.

- Q:How is fiberglass fabric dyed or colored?

- Fiberglass fabric can be dyed or colored using a variety of methods. One common technique is to use a process called solution dyeing, where the color is added to the raw materials before they are spun into fibers. This ensures that the color is evenly distributed throughout the fabric and is resistant to fading or washing out. Another method is to apply the color to the fabric after it has been woven or knitted. This can be done through a process called piece dyeing, where the entire fabric is immersed in a dye bath and then washed and dried. Alternatively, the color can be applied using a printing technique, where a design or pattern is transferred onto the fabric using colored inks. In some cases, fiberglass fabric can also be colored through a post-treatment process. This involves applying a color coating or pigment to the surface of the fabric, which can enhance its appearance and provide additional protection against UV rays or other environmental factors. It is important to note that the specific method used to dye or color fiberglass fabric can depend on various factors, including the desired color, the type of fabric, and the intended application. Additionally, certain dyes or pigments may be more suitable for fiberglass fabric than others, depending on their compatibility and resistance to chemicals or heat. Therefore, it is crucial to consult with experts or manufacturers to determine the best coloring method for a particular fiberglass fabric project.

- Q:Can fiberglass fabric be used for reinforcement in marine applications?

- Yes, fiberglass fabric can be used for reinforcement in marine applications. Fiberglass fabric is a popular choice for reinforcing and strengthening various parts of boats and other marine structures. It is known for its high strength-to-weight ratio, making it an ideal material for improving the structural integrity of marine components. Fiberglass fabric is commonly used to reinforce hulls, decks, bulkheads, and other parts of boats. It is also used in the construction of sailboats, powerboats, yachts, and other watercraft. The fabric can be applied in multiple layers, providing additional strength and durability. One of the key advantages of fiberglass fabric in marine applications is its resistance to water and corrosion. It does not absorb water, making it highly suitable for marine environments where exposure to moisture, saltwater, and other harsh conditions is common. Fiberglass fabric is also resistant to UV radiation, which is crucial for maintaining the structural integrity and appearance of marine components. Furthermore, fiberglass fabric offers excellent dimensional stability, meaning it can retain its shape and strength over time. This is especially important in marine applications where boats and structures are subjected to constant movement, vibrations, and varying loads. In summary, fiberglass fabric is a versatile and reliable material for reinforcing marine applications. Its high strength-to-weight ratio, resistance to water and corrosion, and excellent dimensional stability make it a popular choice among boat builders and marine engineers.

- Q:Can fiberglass fabric be used in corrosive environments?

- Yes, fiberglass fabric can be used in corrosive environments. Fiberglass fabric is known for its excellent resistance to corrosion, making it a suitable choice for applications where exposure to corrosive substances is expected. The fabric is made from woven fiberglass fibers, which are inherently resistant to many chemicals, including acids, alkalis, and solvents. Additionally, fiberglass fabric can withstand high temperatures and is non-reactive, which further enhances its suitability for corrosive environments. It is commonly used in industries such as chemical processing, oil and gas, and marine, where protection against corrosion is crucial. However, it is important to note that the specific type and quality of the fiberglass fabric used may vary, and it is advisable to consult the manufacturer or supplier to ensure the fabric's compatibility with the specific corrosive environment in question.

- Q:Anticorrosion floor construction

- Forklift truck can withstand long-term rolling, so that the ground heavy corrosion resistance, strong acid and alkali resistance, chemical solvents, impact resistance, anti - ground cracks. Scope of application: surface, wall and equipment surface of electroplating factory, battery factory, chemical plant, electrolytic bath, pharmaceutical factory, acid and alkali neutralization pool, etc..

- Q:Can fiberglass fabric be used for insulation in pharmaceutical facilities?

- Yes, fiberglass fabric can be used for insulation in pharmaceutical facilities. It is a commonly used material due to its excellent thermal insulation properties, fire resistance, and ability to withstand high temperatures. Additionally, it is lightweight, durable, and cost-effective, making it suitable for various applications in pharmaceutical facilities.

- Q:How does fiberglass fabric perform in terms of thermal conductivity?

- Fiberglass fabric has low thermal conductivity, meaning it is a poor conductor of heat.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Carbon Fiber Weaving Fabrics

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 5000KG kg

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords