Butimen Coated Fiberglass Geogrid Used on Road Reinforce

- Loading Port:

- Qingdao

- Payment Terms:

- TT or LC

- Min Order Qty:

- 20000 m²

- Supply Capability:

- 500000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

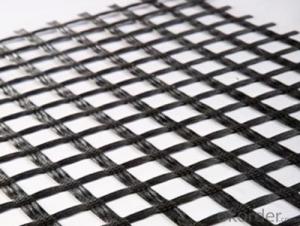

Structure of Butimen Coated Fiberglass Geogrid:

Butimen Coated Fiberglass Geogrid is excellent composite material used for road bed reinforcement and soft soil foundation improvement. It has become an indispensable material in treatment of reflection cracks on asphalt road surface. The products are semi-rigid mesh base made from high-strength alkaline-free glass fiber through international advanced process and subjected to surface coating. It has a high tensile strength and a lower elongation both vertically and horizontally. Moreover, it has good resistance to high and low temperature, aging and corrosion. It is widely used in Asphalt wall, railway foundation, dike slope, runway and sand harnessing.

Main Features of Butimen Coated Fiberglass Geogrid:

fiberglass geogrid for soil reinforcement

fiberglass geogrid

High tensile strength, low elongation

High stability

Butimen Coated Fiberglass Geogrid Images

Butimen Coated Fiberglass Geogrid Specification

Glass Fiber Geogrid GGF80 Technical Specification | |||

Property | Test Method | Unit | Index |

Wide Width Tensile Strength | |||

MD | KN/M | ≥80 | |

CMD | KN/M | ≥80 | |

Elongation At Break | ≤4 | ||

Grid | MM | 25.4×25.4 | |

Width | M | 1~6 | |

Packaging | Details | ||

Roll Dimensions(W×L) | According to customer requirements | ||

Square Meters Per Roll | |||

Estimated Roll Weight | |||

It is widely used in Asphalt wall, railway foundation, dike slope, runway and sand harnessing.

FAQ

We have organized several common questions for our clients,may help you sincerely:

Q: How about your company?

A:Our company are one of the largest geosynthetic products supplier in the world.We have the products experience more than 20 years.Already export to USA/Germeny/Australia/Zambia/Brazil etc.more than 20 countries.Almost 10years.Our products including Geocell/Fiberglass Geogrid/Geomembrane/Geotextile/Geonet etc.

Q.Does your products have good qualitity?

A:Yes,we have do many big projects such as the 2008 Beijing Olympic BIRD NEST. Divert water from the south to the north project. And our products have CE certificate also.

Q:How long can we receive the products after purchase?

A:In the purchase of product within three working days, We will arrange the factory delivery as soon as possible. The pecific time of receiving is related to the state and position of customers.Commonly 15-20 working days can be delivery.

- Q:Are geogrids suitable for use in contaminated soil conditions?

- Yes, geogrids are suitable for use in contaminated soil conditions. Geogrids are made from high-strength materials that are resistant to chemical degradation, making them effective in stabilizing and reinforcing soil in contaminated areas. They provide strength and stability to the soil, preventing erosion and improving load-bearing capacity, even in contaminated soil conditions.

- Q:Geogrid per square meter

- Of course, it depends on what kind of material you need the geogrid, what kind of specifications!

- Q:The cheapest two-way plastic geogrid manufacturers, two-way plastic geogrid prices?

- Its elongation rate is only 10% ~ ~ of the original plate of 15%. If the carbon black and other anti-aging materials are added in the geogrid, the utility model has the advantages of good acid resistance, alkali resistance, corrosion resistance, aging resistance and the like.

- Q:The difference between two way steel plastic grille and one way steel plastic grille

- Bi directional steel plastic geogrid is both vertical and horizontal tension requirements, have to do pull test

- Q:GDZ150 type one-way steel plastic welding geogrid D in the construction of the roadbed is horizontal paving also vertical spread?

- Because the direction of the force is mainly perpendicular to the direction of the line, your product is a one-way force of the product; if two-way products do not exist this problem.

- Q:What are the factors to consider when designing with geogrids for reinforced soil walls?

- When designing with geogrids for reinforced soil walls, there are several important factors to consider. Firstly, the type and strength of the geogrid material is crucial. The geogrid should have sufficient tensile strength and stiffness to effectively reinforce the soil and withstand the loads and stresses imposed on the wall. Secondly, the connection between the geogrid and the soil is critical. Proper anchoring and connection methods must be employed to ensure the geogrid remains securely in place and effectively distributes the loads throughout the reinforced soil structure. Additionally, the design should consider the wall height and slope angle, as these factors impact the stability and performance of the reinforced soil wall. The geogrid spacing and orientation must be determined based on these parameters to achieve the desired stability and load-bearing capacity. Other factors such as soil properties, water drainage, and environmental conditions should also be taken into account to ensure the long-term performance and durability of the reinforced soil wall. Overall, a comprehensive understanding of these factors is essential for successful design and construction with geogrids in reinforced soil walls.

- Q:How many steel wire two-way steel plastic geogrid tensile strength reached 100kn/m

- It depends on the number of steel wires, and the number of wires, and then the,

- Q:Can geogrids be used in reinforcement of stormwater management systems?

- Yes, geogrids can be used in the reinforcement of stormwater management systems. Geogrids are commonly employed to enhance the stability and strength of soil structures, such as retaining walls, slopes, and embankments. In stormwater management systems, they can be utilized to reinforce the base and sidewalls of stormwater ponds, channels, and underground storage systems. This reinforcement helps to prevent soil erosion, maintain structural integrity, and improve overall performance of the stormwater management system.

- Q:Can geogrids be used in slope stabilization for railway embankments in permafrost regions?

- Yes, geogrids can be used in slope stabilization for railway embankments in permafrost regions. Geogrids provide reinforcement and stabilization to the soil, reducing the risk of slope failure and ensuring the stability of the embankment. They are particularly effective in permafrost regions where the frozen ground can be prone to thawing and subsidence. Geogrids improve the overall strength of the embankment, minimize soil movement, and help to maintain the integrity of the railway infrastructure in these challenging environments.

- Q:Are geogrids suitable for reinforcement of airport runways?

- Yes, geogrids are suitable for reinforcement of airport runways. Geogrids are commonly used in civil engineering projects to enhance the stability and strength of soil and pavements. They provide excellent reinforcement and can effectively distribute loads, reduce rutting, and prevent cracking on airport runways, thereby improving their durability and performance.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Butimen Coated Fiberglass Geogrid Used on Road Reinforce

- Loading Port:

- Qingdao

- Payment Terms:

- TT or LC

- Min Order Qty:

- 20000 m²

- Supply Capability:

- 500000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords