Best Quality of Cold Rolled Steel Coil from China

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Structure of Cold Rolled Steel Description:

The raw material of cold rolled steel coil/sheet is high quality hot rolled product, and after pickling continuous rolling, degreasing, annealing,skin pass,slitting and cut to length line etc. Along with it many kinds of new technology and new process of global cold rolling production have been applied. Therefore the quality of the goods could be guaranteed. The product is widely used in outdoor and interior decoration, furnishing manufacturing, home appliance, automobile etc.

2.Main Features of the Cold Rolled Steel:

• Excellent process capability

• Smooth and flat surface

• Workability, durability

• Excellent heat resistance performance

• High strength

• Good formability

• Good visual effect

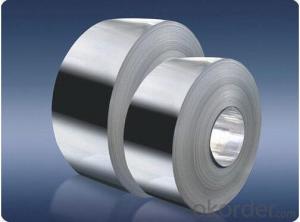

3.Cold Rolled Steel Images

4.Cold Rolled Steel Specification

Standard:AISI,ASTM,DIN,GB,JIS,JIS G3302 ASTM 653M EN10142

Grade: Q195~Q345

Thickness: 0.16mm~1.5mm,0.16-1.5mm

Width: 1250,600-1250mm

Coil weight:3-12 MT

Coil ID:508/610mm

Chemical composition:

C | Si | Mn | Cr | Ni | P | S |

0.150 | 0.476 | 11.231 | 12.50 | 0.900 | 0.039 | 0.010

|

5.FAQ of Cold Rolled Steel

We have organized several common questions for our clients,may help you sincerely:

1.How about your company?

A world class manufacturer & supplier of castings forging in carbon steel and alloy steel,is one of the large-scale professional investment casting production bases in China,consisting of both casting foundry forging and machining factory. Annually more than 8000 tons Precision casting and forging parts are exported to markets in Europe,America and Japan. OEM casting and forging service available according to customer’s requirements.

2.How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

3. How long can we receive the product after purchase?

Usually within thirty working days after receiving buyer’s advance payment or LC. We will arrange the factory manufacturing as soon as possible. The cargo readiness usually takes 15-25 days, but the shipment will depend on the vessel situation.

- Q:Are steel sheets suitable for roofing?

- Yes, steel sheets are suitable for roofing. Steel is a durable and strong material that can withstand harsh weather conditions, such as heavy rain, snow, and strong winds. It is also resistant to fire, pests, and rot, making it a reliable choice for long-term roofing solutions. Steel sheets are lightweight and easy to install, reducing labor and installation costs. Additionally, they are available in a variety of colors and finishes, allowing for customization to match the aesthetic of any building. Overall, steel sheets provide excellent protection and longevity, making them a popular choice for roofing applications.

- Q:How do steel sheets handle electromagnetic interference?

- Steel sheets can act as a shield against electromagnetic interference due to their high electrical conductivity and magnetic properties. They can effectively block or attenuate electromagnetic waves, reducing the impact of interference on electronic devices or systems.

- Q:Can steel sheets be used for cladding or facade systems?

- Yes, steel sheets can be used for cladding or facade systems. Steel is a durable and versatile material that offers excellent structural support and weather resistance. It can be shaped into various profiles and finishes, making it suitable for creating aesthetically pleasing and functional building facades.

- Q:What is the process of applying insulation materials to steel sheets?

- The process of applying insulation materials to steel sheets typically involves several steps. First, the steel sheets are thoroughly cleaned and prepared to ensure proper adhesion of the insulation material. Then, a layer of adhesive is applied to the surface of the steel sheets. Next, the insulation material, such as foam or fiberglass, is cut and shaped to fit the dimensions of the steel sheets. The insulation material is then carefully placed onto the adhesive-coated steel sheets, ensuring proper alignment and coverage. Finally, the insulation material is pressed or secured in place to ensure a tight bond with the steel sheets.

- Q:How do steel sheets perform in fire-rated applications?

- Due to their high melting point and excellent structural integrity, steel sheets are highly effective in fire-rated applications. When exposed to fire, steel sheets retain their strength and stability, making them a dependable choice for fire-resistant construction. Furthermore, steel sheets do not contribute to the spread of fire or the release of harmful fumes, thereby enhancing the safety of occupants during a fire incident. In addition, steel sheets offer exceptional thermal insulation, preventing the transfer of heat from the fire to other parts of the building. This characteristic enables the containment of fires and minimizes the resulting damage. In conclusion, utilizing steel sheets in fire-rated applications offers a sturdy and efficient solution for fire protection in buildings.

- Q:Are the steel sheets resistant to vibration or shock?

- Steel sheets are generally resistant to vibration and shock due to their high strength and durability. Steel is known for its ability to withstand external forces like vibrations and shocks, thanks to its rigid nature. This allows steel to effectively absorb and distribute energy caused by vibrations or shocks, preventing any significant damage or deformation. In various industries, such as construction, automotive, and aerospace, steel sheets are commonly used because their resistance to vibrations and shocks is crucial. However, it's important to consider that the exact resistance of steel sheets to vibration or shock depends on factors like thickness, steel quality, and the specific magnitude and frequency of the vibrations or shocks.

- Q:Are steel sheets suitable for automotive body parts?

- Yes, steel sheets are suitable for automotive body parts. Steel is a commonly used material in the automotive industry due to its strength, durability, and ability to withstand high impact. Steel sheets provide excellent structural integrity and can be easily formed into various shapes to create automotive body panels. Additionally, steel is cost-effective and readily available, making it a preferred choice for manufacturing automotive body parts.

- Q:How are steel sheets used in construction?

- Steel sheets are commonly used in construction for various purposes such as roofing, wall cladding, and structural support. They provide strength, durability, and resistance to harsh weather conditions. Steel sheets can be formed into different shapes and sizes, making them versatile for a wide range of construction applications.

- Q:What are the different surface gloss levels available for steel sheets?

- The different surface gloss levels available for steel sheets include matte, satin, and high gloss.

- Q:How are steel sheets produced?

- Steel sheets are typically produced through a process called hot rolling, where steel ingots or billets are heated and passed through multiple sets of rollers to reduce the thickness and shape them into flat sheets.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Best Quality of Cold Rolled Steel Coil from China

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords