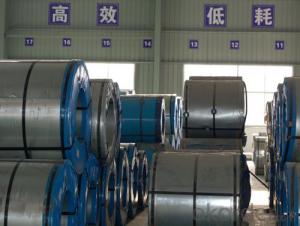

Best Quality Hot Dip Galvanized Steel Coil Regular Spangle

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 50000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Steel Specification:

Thickness: 0.2-3.0mm

Width: 600-1500mm

Coating Mass: Z08,Z12,Z18,Z20,Z22,Z25,Z27,Z35

Z80,Z120,Z180,Z200,Z220,Z250,Z275

Tolerance for thickness,width,flatness and so on conform to the requirements of JIS G3302 or ASTM A653M/924M

Coil ID can be either 508mm or 610mm, maximum coil OD is 2000mm

The speicfication of ASTM Such as A653m,A924 M and so on have been updated to the latest revisions

Application:

BUILDING & CONSTRUCTION

Floor decks, ceilings, verandas, rolling doors, warehouse, partitions, sheds, gutters, wall, underground piping, sashes, beams, fences, scaffolding, indoor decorations, ducts, ventilating pipes, steel frames and cable trays.

ELECTRICAL APPLIANCES

Freezers, video recorder cases, motor cases, lighting fittings, water heaters, washing machines, refrigerators, stoves, air conditioners, dehumidifiers, fluorescent light housings, electrical heaters, toasters, microwave oven enclosures and switch boxes.

TRANSPORTATION

Containers, under body panels, bus & truck body panels, fuel tanks, noise screens, highway signs, air cleaners, conveyor systems and guard rails.

AGRICULTURAL EQUIPMENT

Barns, drying machines, animal houses, hoppers, irrigation systems, greenhouses, water tanks, sheds, silos, agricultural implements and feeders.

FURNITURE & OTHERS

Vending machines, drums, cans, pails, sauna inner parts, chimney pipes, entertainment machines, solar collectors, office equipment, steel furniture, tool boxes, garages and waste bins.

COMPUTER'S APPLIANCES

Computer shells and communication instruments。

Surface Treatment:

Chromating treatment or anti-finger print

Surface Finished:

REGULAR SPANGLE:

Regular spangle is also called normal spangle which is naturally formed without any additional treatment during galvanizing.

MINI SPANGLE:

The spangle is restrained and formed as mini spangle by reducing the lead content in the zinc liquid or by blowing the zinc powder from the equipment installed on the zinc pot.

EXTRA SMOOTH:

The mini spangle is further skin-passed to produce the extra smooth surface.

- Q:Can steel sheets be used for manufacturing security doors?

- Yes, steel sheets can be used for manufacturing security doors. Steel is a strong and durable material that provides excellent security and protection. It can withstand forced entry attempts and offers resistance to break-ins. Steel sheets are commonly used in the construction of security doors due to their high tensile strength, which makes them difficult to bend or break. Additionally, steel doors can be reinforced with additional features such as multiple locks, deadbolts, and security bars for enhanced security. Overall, steel sheets are a reliable choice for manufacturing security doors.

- Q:What is the difference between plain carbon steel sheet and stainless steel sheet?

- Plain carbon steel sheet and stainless steel sheet are both types of steel sheets, but they have several distinct differences. The main difference between plain carbon steel sheet and stainless steel sheet lies in their composition and properties. Plain carbon steel sheet is primarily made up of iron and carbon, with small amounts of other elements such as manganese and silicon. It is known for its strength and durability, making it suitable for a wide range of applications. However, plain carbon steel is prone to rust and corrosion when exposed to moisture or certain chemicals. On the other hand, stainless steel sheet is made up of iron, carbon, and a minimum of 10.5% chromium. This addition of chromium forms a protective layer on the surface of the steel, known as a passive film, which prevents corrosion and rusting. Stainless steel is highly resistant to stains, heat, and corrosion, making it ideal for applications where hygiene and durability are crucial, such as in the food and medical industries. Another significant difference between the two types of steel sheets is their appearance. Plain carbon steel sheet has a dull grey finish, while stainless steel sheet has a shiny, reflective surface. This aesthetic difference is often a consideration in industries where the visual appeal of the material is important, such as architectural or interior design applications. Furthermore, stainless steel sheet has a higher price point compared to plain carbon steel sheet. This is due to the additional alloying elements, such as chromium and nickel, which are added to enhance its corrosion resistance and other properties. The higher cost of stainless steel is often justified by its superior performance and longevity in corrosive environments. In summary, the key differences between plain carbon steel sheet and stainless steel sheet are their composition, properties, appearance, and price. Plain carbon steel is strong but prone to rust, while stainless steel is corrosion-resistant and has a shiny finish. The choice between the two depends on the specific requirements of the application, including the need for corrosion resistance, aesthetics, and budget.

- Q:Are steel sheets suitable for underground applications?

- Yes, steel sheets are suitable for underground applications. Steel is a strong and durable material that can withstand high pressure and provide structural stability in underground environments. It is commonly used in underground construction projects such as tunnels, mines, and underground storage facilities. Steel sheets are resistant to corrosion and can effectively protect underground structures from water, soil, and other external elements. Additionally, steel sheets offer cost-effectiveness and ease of installation, making them a practical choice for underground applications.

- Q:Are steel sheets suitable for architectural cladding?

- Yes, steel sheets are suitable for architectural cladding. Steel is a durable and versatile material that offers a range of benefits for cladding applications. Its strength and rigidity make it capable of withstanding harsh weather conditions, including strong winds, heavy rain, and snow. This durability ensures that the cladding will last for many years without requiring frequent maintenance or replacement. In addition to its durability, steel sheets provide a sleek and modern aesthetic to buildings. They can be finished in various ways, including painting, powder coating, or applying a metallic finish, allowing for endless design possibilities. Steel cladding can be used to achieve a contemporary or industrial look, making it a popular choice for commercial and residential buildings alike. Steel sheets are also highly resistant to fire, pests, and rot, making them a safe and long-lasting choice for cladding. They are also relatively lightweight, which can help reduce construction costs and make installation easier. Furthermore, steel is an environmentally friendly material. It is recyclable, making it a sustainable choice for cladding. Steel cladding can also help improve energy efficiency by providing better insulation and reducing heat transfer, resulting in lower energy consumption for heating and cooling. Overall, steel sheets are a suitable option for architectural cladding due to their durability, aesthetic appeal, safety features, sustainability, and energy efficiency benefits.

- Q:What is the average yield strength of steel sheets?

- The average yield strength of steel sheets varies depending on the specific grade and thickness of the steel. However, it typically ranges from 250 to 400 megapascals (MPa).

- Q:Are the steel sheets perforated or solid?

- The steel sheets are perforated.

- Q:Can steel sheets be perforated?

- Yes, steel sheets can be perforated. Perforating steel sheets involves creating a pattern of holes or perforations in the material, which can be achieved through various methods such as punching, drilling, or laser cutting. This process is commonly used in industries like construction, automotive, and manufacturing for applications such as ventilation, filtration, acoustic panels, or decorative purposes.

- Q:What is the average wind load capacity of steel sheets?

- The average wind load capacity of steel sheets can vary depending on various factors such as the thickness of the sheet, the type of steel used, and the specific design and installation of the structure. However, steel sheets are known for their high strength and durability, making them capable of withstanding significant wind loads. Typically, steel sheets used for roofing or cladding applications are designed to meet specific wind load requirements based on regional building codes and standards. These standards take into account factors such as the geographical location, building height, exposure category, and wind speed. To determine the wind load capacity of steel sheets, engineers and architects use calculations and simulations to analyze the forces exerted by the wind on the structure. They consider factors such as wind pressure, building orientation, surface area, and the shape and profile of the steel sheets. In summary, the average wind load capacity of steel sheets cannot be generalized as it varies based on several factors. It is crucial to consult with a structural engineer or building professional to determine the appropriate wind load capacity requirements for a specific steel sheet application.

- Q:How do steel sheets perform in extreme temperatures?

- Steel sheets have excellent performance in extreme temperatures. Steel is known for its high strength and durability, which allows it to withstand both extremely hot and extremely cold conditions. In high temperatures, steel sheets maintain their structural integrity and do not deform or melt. Similarly, in cold temperatures, steel does not become brittle or lose its strength. This makes steel sheets a reliable choice for various applications in extreme temperature environments.

- Q:What are the different sheet metal stamping techniques for steel sheets?

- There are several sheet metal stamping techniques for steel sheets, including blanking, piercing, bending, deep drawing, and embossing.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Best Quality Hot Dip Galvanized Steel Coil Regular Spangle

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 50000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords