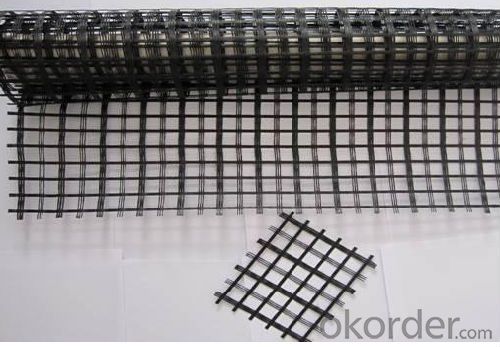

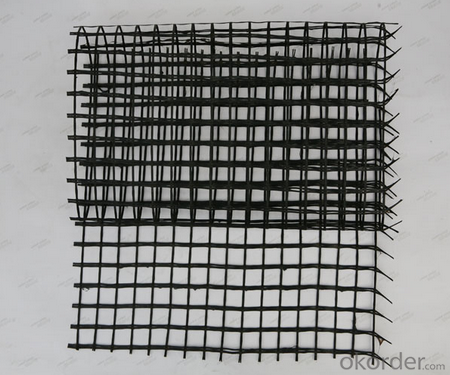

Basalt Geo-Grid with High Quality and Best Price

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1000 kg

- Supply Capability:

- 100000 kg/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Description:

Fiberglass geogrid(Glass fiber grid) is plane network shape material that selects excellent reinforcement ype non-alkali glass fiber yarn, is weaved into base material by using foreign advanced warp knitter, uses warp knitting directional structure ,makes full use of yarn strength in textile, improves its chemical performance ,makes it has good tensio resistance, tearing resistance and creep resistance, and formed by excellentm modified asphalt (bitumen) mixture ,protects glass fiber base material fully and improves wearing resistance and shearing force resistance of base material so as to mak road surface reinforce ,to prevent highway harm such as crack and rut from occurring and to solve the problem that asphalt road surface is diffcult for reinforcement.

Specifications:

1.Fiberglass Geogrid size: EGA50/50 ---200/200

2.Price:USD 0.2 -- 1.0/Sq.m

3.Customize.

4.Found in 2003.

5.Exported 10 years

Features :

basalt fiber mesh fabric with high tensile strength, good compatibility with the mixture of asphalt can be very good against bio-erosion and climate change. As the asphalt mixture mixing temperatures up to 190 ℃ or more, the temperature of the basalt fiber mesh fabric mesh fabric in a variety of species present in a strong competitive advantage.

Standard: Standard, Traffic, "Highway Engineering basalt fiber and its products Part 3 of basalt fiber mesh cloth" Plan No.: JT2007-37, is currently approved by experts.

Ministry of Construction Standards "fiber reinforced composite grid" building standard (2008) 103 Man, currently being drafted.

Application:

laying cement concrete pavement, bridge pier reinforcing the dam and various building and construction joint surface of walls, pieces of cement mortar or concrete pouring.

FAQ:

1.What is the delivery time ?

We can promise you a short lead time ( 10-15days )

2.Are you a factory?

We have factory and can offer you direct price,and we have 10 yeas experiences

- Q:How to make the lining of tank acid-proof and anticorrosion.

- If it is metal can, cleaning, descaling and brushing anticorrosion lacquer will be fine.

- Q:How to produce glass steel?

- Material: Glass cloth, resin, curing agent tool: Glass?pane or polyester i thin?film process: According to the specifications for glass?reinforced?plastics, glass plane or polyester i thin film should be prepared and then you should tail glass cloth in accordance with requirements. At first, you should compound resin, and then you should put cloth that already have been tailed on the glass pane and cover it with compounded resin until its thickness meets requirements after removing all bubbles in it. After that, you should continue to cover it with polyester i thin film without bubbles and put a piece of glass on it if you want it more neat. A new product is ready after taking off the glass fiber reinforced plastics and trimming it carefully.

- Q:What is the production process of FRP grille?

- Reciprocating fiber winding technology (belonging to the fixed length method): in this process, dipping tank with mandrel rotating reciprocating motion, long fiber glass fiber with a certain angle relative to the mandrel axis auxiliary, auxiliary angle (i.e. winding angle) by dipping groove movement speed and mandrel speed ratio control, control of electric glue impregnation groove translational motion by a computerized machine. The number of plies increases gradually to the wall thickness of the design. When the winding is finished, the resin in the product is basically solidified. After solidification, the core die is removed from the glass tube.

- Q:Can glass fiber be used for cement components

- Glass fiber reinforced cement products uses glass?fiber to produce cement component. The glass fiber should be alkali resistant glass fiber twist roving, alkali resistant glass fiber chopped strand and alkali resistant glass fiber mesh cloth which comply with JC/T5,72 or JC/T 841 requirements. The cement should be in accordance with JC7/14 and portland cement should comply with the provisions of GB 175. Portland cement must be mixed with absorable Ca (O H), alkali materials or acrylic?acid emulsion with the content of alkali resistant glass fiber is higher than 16%.

- Q:Can you describe the production process of glass fiber and the production process?

- The production process of glass fiber generally includes: Purchase the raw materials, mixed according to the formula, and then transfer to the glass furnace for melting and refining, after operation channel flow to the bushing, the sizing agent after coating by wire drawing machine traction, forming the original cake, and then flow to the rear section reprocessing procedures (usually a short cut, winding, weaving, puffing and twisting) or sell (direct yarn)

- Q:What are the differences between glass fiber and asbestos?

- Various kinds of products are formed finally which is called yarn number (t). The content of chrysotile is the most abundant. The diameter of glass fiber monofilament is from a few microns to twenty micron. 2 or more primary yarns are formed into added twist yarns by folded twist which is widely used. Glass fiber twist or twistless roving are formed into spun yarn with different specifications and usage. There mainly are alkali free. Composite line is formed by two or more fold twist. Glass fiber is a kind of inorganic nonmetal material with excellent performance. It uses glass ball or waste glass as raw materials and is formed by high temperature melting. It mainly is used for producing glass?fiber products. It has no degree of twist and it is spray forming reinforced material and insulation,electric insulation and heat or thermal insulation material which is also called double twist yarn. It mainly is used for hand lay-up glass?reinforced?plastics and is known as detwisting yarn in glass fiber industry. The meaning of metric system number. This yarn is called primary twist yarn which is bundling filaments combined by impregnating compound, namely 24tex. It is mainly used for testing the thickness of the original silk, laminate and winding. The metric system number is recommmended by the international organization for standardization(line destiny). 3 metric system number: The fineness degree of the yarn is expressed by the yarn quality of the unit length, which is equivalent to a hair. The smaller the number is, the thicker the yarn is. Monofilament is equal to 20tex. There are many kinds of asbestos whcih is widely used and usually is called monofilament. The former is a fixed length, the latter is a fixed weight.

- Q:Definition of glass fiber reinforced plastic doors and windows

- The unsaturated resin is used as the subtrate material. it have many advantages such as sound insulation and so on. Glass?reinforced?plastics is also called glass fiber reinforced material with lightweight property. Glass?reinforced?plastics doors and windows use glass fiber twistless roving and fabric as reinforcement material. It is a new type of composite material developed abroad in early twentieth Century and can add other mineral filler.

- Q:What is glass fiber?

- It has the advantages of good insulation and corrosion resistance. The diameter of monofilament is from several microns to twenty micron. It uses glass ball or waste glass as raw material and is produced by high temperature melting. Glass fibre is usually used as reinforced composite materials, but its drawback is crisp. It features with poor abrasion resistance, good heat resistance and is used as electrical insulating materials and heat/thermal insulation materials. Its diameter is equal to that of a hair. Each bundle fiber raw silk is formed by hundreds or even thousands of monofilament with high mechanical strength. Glass fiber is a kind of inorganic nonmetal material with excellent performance.

- Q:What is the difference between the glass and glass?reinforced?plastics?

- Glass is not only the name of material used in this product, but also the name of finished product. Glass?reinforced?plastics, the name of the material, is a heating fixed plastics compositing glass fiber with a variety of other material.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Basalt Geo-Grid with High Quality and Best Price

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1000 kg

- Supply Capability:

- 100000 kg/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords