ASTM HDPE Geomembrane for Aquiculture and Landfill Project Use

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 5000 m²

- Supply Capability:

- 200000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

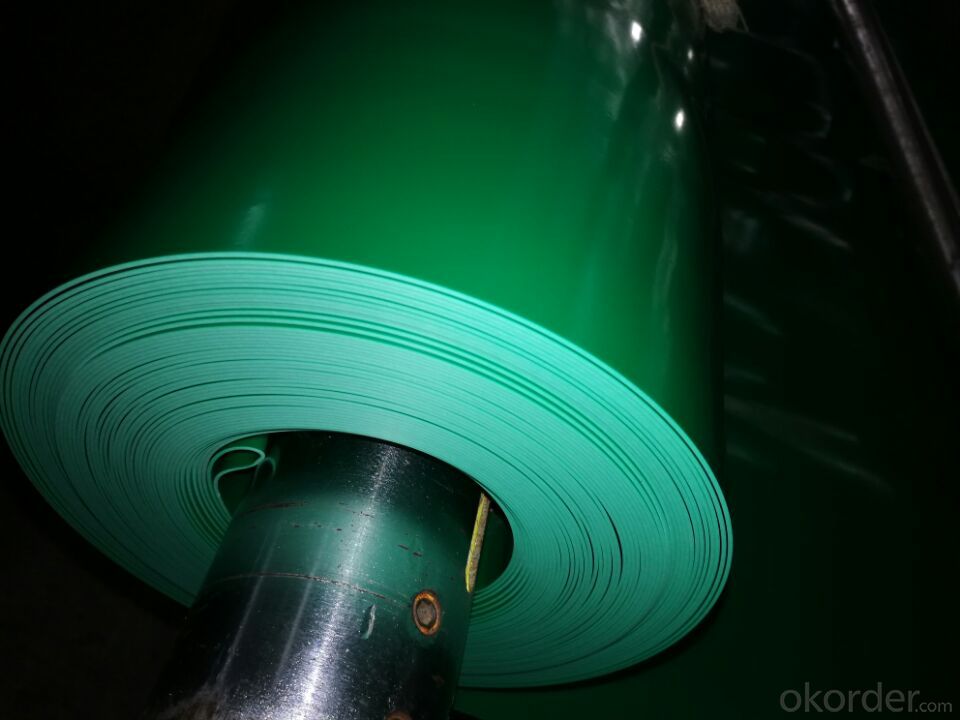

HDPE Geomembrane Detail Specifications:

Type: | Geomembranes | Place of Origin: | Shandong, China (Mainland) | Brand Name: | CMAX |

Model Number: | 0.1mm-4.0mm | Material: | EVA, HDPE, LDPE, LLDPE, PVC, HDPE | Thickness: | 0.1mm - 4.0mm |

Color: | white, black, red ect. | Roll width: | 1m-8m | Roll length: | 50-100m |

MOQ: | 100 m2 | Certification: | CE/ISO9001/ ISO14001 | Sample: | available for free |

Package: | by PP woven bag | Payment: | by T/T |

HDPE Geomembrane Feature:

--Good mechanical properties

--High tear strength, deformation and adaptable, puncture resistance,

--Anti-aging, anti-ultraviolet-resistant,

--Anti oil and salt, pH, anti-corrosion, high temperature-resistant, non-toxic, long service life. water,

--Drainage, seepage, the good effect of moisture, width, thickness of the full range of specifications

and low cost, simple construction.

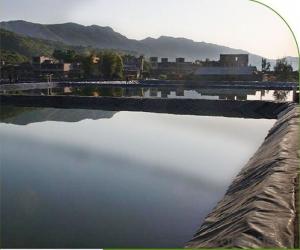

HDPE geomembrane Application:

1) Environmental protection sanitation (such as solid waste landfills, sewage treatment plants, power plants Chi-conditioning, industrial, hospital solid waste, etc.) .

2) Water (such as rivers, lakes and reservoirs of the anti-dam, plugging, reinforcement of the canal seepage, the vertical wall of the heart, slope protection, etc.).

3) Municipal Engineering (subway, on the ground floor of the building, planted roof, the roof garden of anti-seepage, sewage pipes lining, etc.).

4) Landscape (man-made lake, river, reservoir, golf courses reservoirs of the substrate, slope protection, green lawn of the waterproof moisture, etc.).

5) Petrochemical (chemical plants, oil refineries, gas storage tanks of the anti-chemical reaction tanks, sedimentation tanks of the lining, etc.).

6) Mining (washing and pool heap leaching, the ash-field, dissolved, precipitation, the yard, the tailings seepage substrates, etc.) .

HDPE Geomembrane Packaging & Delivery:

Packaging Details: | HDPE geomembrane are packed into roll in PP woven geotextile or as client' s request |

Delivery Detail: | in 10 days after receive advance payment |

HDPE Geomembrane Photos:

- Q:How to paste anti-explosion glass film?

- Explosion-proof membrane is generally adhered to the inside of the glass. Before pasting, the glass must be absolutely clean, and the part to be pasted membrane must be repeatedly washed. If there is left any tiny dust on the glass, it will affect the adhesive force of the architectural membrane, for the veneer of the membrane and the glass can only be firmly adhered in the vacuum state.

- Q:Can geomembranes be used in decorative pond installations?

- Yes, geomembranes can be used in decorative pond installations. They are often used as a flexible and durable lining material to prevent water leakage and provide a smooth surface for pond features such as waterfalls, fountains, and rock formations.

- Q:Are geomembranes resistant to algae growth?

- Yes, geomembranes are generally resistant to algae growth. They are designed to be impermeable and provide a barrier against water and other substances, which prevents the growth of algae. Additionally, geomembranes are often made from materials that are not conducive to algae growth, such as high-density polyethylene (HDPE) or polyvinyl chloride (PVC). However, it is important to note that proper installation and maintenance of geomembranes are essential to ensure their effectiveness in preventing algae growth.

- Q:What is the difference between the dredging of the soil and the soil pipe?

- The geotechnical membrane is made of plastic film as the impervious material, and the composite of the non-woven fabric is made of the soil anti seepage material.

- Q:What is national standard of geomembrane?

- Polyethylene geomembrane new national standard GB / T17643-2011. The new standard increases single rough geomembrane and double rough geomembrane and delete EVA geomembrane.

- Q:What is the welding method of geotextile?

- It is easy to weld the geotextiles that manual rolling and paving is enough. The surface should be flat with some deformation allowance left. The long or short nonwoven geotextiles are often bonded by lapping, seaming and welding. The seamed and welded overlap is generally more than 0.1m wide. The lapped overlap is generally more than 0.2m wide. For geotextiles with long exposure time, methods of welding and seaming are recommended. Continue seaming until the all the work is completed. (disconnected seaming is not allowed.) Before being bonded, the overlaps should not be less than 150mm wide. The minimum distance of seams to the edges (the exposed edge of material) is 25mm. The thread for seaming should be made from resin with tensile strength no less than 60N, with chemical resistance and UV resistance that are the same with that of geotextile or exceed that of geotextile. Any "missed stitch" should be avoid. Actions should be taken accordingly to prevent emission of soil, particulate matters or foreign matters.

- Q:Geomembrane is how the construction

- Geomembrane construction methods are as follows: 1, in the determination of the scope of laying. Laying the composite geomembrane according to the requirements before the laying of sand cushion on the roadbed, laying width according to the design requirements set; 2, laying when not allowed to fold, try to tighten. 3, laying composite geomembrane, the sand cushion layer surface is smooth, no hard protrusion, paved and filled with sand in time to avoid the sun for a long time before the direct 5, composite geomembrane spread, the timely filling of the filler, to be covered with light after the use of light compaction mechanical compaction, only when the composite geomembrane laying, horizontal lap and longitudinal lap length to meet the design requirements; 6, composite geomembrane according to the design requirements can be divided into longitudinal and transverse force in two forms, the laying of composite geomembrane before the understanding of the design of the composite geomembrane Intent, in strict accordance with the design requirements laying.

- Q:What are the considerations for geomembrane selection in oil and gas pipeline protection?

- The considerations for geomembrane selection in oil and gas pipeline protection include factors such as chemical resistance to hydrocarbons and other chemicals present in the pipeline, durability to withstand harsh environmental conditions, flexibility to accommodate ground movement and settlement, puncture resistance to prevent leaks, and compatibility with installation methods and techniques. Additionally, the geomembrane should comply with industry standards and regulations, provide cost-effectiveness, and offer ease of maintenance and repair.

- Q:Can geomembranes be used for floating covers?

- Yes, geomembranes can be used for floating covers. Geomembranes are flexible, impermeable liners that can be installed on the surface of water bodies to create floating covers. These floating covers can be used for various purposes such as preventing evaporation, minimizing contamination, or controlling odors.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

ASTM HDPE Geomembrane for Aquiculture and Landfill Project Use

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 5000 m²

- Supply Capability:

- 200000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords