Anti-Skid Needle Punched Non Woven Geotextile with High Strength CMAX

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 12000 m²

- Supply Capability:

- 600000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Introduction of Geotextile

Good flexibility, permeability, filtration, sepatation and easy for construction.

Application of Geotextile

CMAX Geotextile has excellent permeability, acquired, durablity, which can be widely used in railway, highway, movement hall, dams, hydraulic structures, hence hole, coastal shoal,reclamation, environmental protection and other projects.

The main products are Synthetic staple fibers needlepunched non woven geotextiles and slit and split film yarn woven geotextiles.

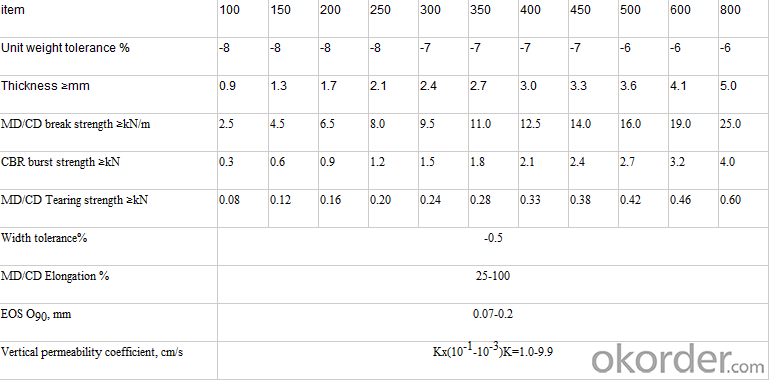

Specifications:100GSM-1500GSM

length:50m-100m

width:1m-8m

material:100%PET

Packaging Details: pp woven bags or at your request

Delivery Detail: 15 days

Technical Specification

Packing

FAQ

Q: What kind of payments does jenor support?

A: T/T, L/C, Cash are accepted.

Q: Do you charge for the samples?

A: Accordeing to our company policy, the samples are freee, we only charge the freight fee. And we will return the freight fee during the next order.

Q: Can you produce according to customers' design?

A: Sure, we are professional manufacturer, OEM and ODM are both welcome.

Q: Do you have other products?

A: Yes, please check the pictures:

- Q:How do geotextiles help with reinforcement of geogrid reinforced walls?

- Geotextiles are used in conjunction with geogrids to reinforce walls by providing additional support and stability. They prevent soil erosion and migration, acting as a barrier between the geogrid and the surrounding soil. This helps to distribute the load evenly, reducing the risk of wall failure and improving the overall strength and durability of the structure.

- Q:How do geotextiles help with embankment stabilization?

- Geotextiles help with embankment stabilization by providing reinforcement and erosion control. They are placed within the embankment to distribute the load and increase its stability. Additionally, geotextiles prevent soil erosion by allowing water to drain through them while retaining the soil particles, thus preventing soil loss.

- Q:How are geotextiles tested for strength and durability?

- Geotextiles are tested for strength and durability through various methods such as tensile testing, puncture resistance testing, tear resistance testing, and abrasion resistance testing. These tests involve subjecting the geotextiles to controlled forces, pressures, and wear to assess their ability to withstand different environmental conditions and loads.

- Q:Can geotextiles be used for reinforcement in retaining walls?

- Yes, geotextiles can be used for reinforcement in retaining walls. Geotextiles are commonly used in retaining wall construction to provide strength, stability, and improved drainage. They help to distribute the load and prevent soil erosion while allowing water to pass through, making them an effective solution for reinforcing and enhancing the performance of retaining walls.

- Q:Can geotextiles be used in green or sustainable building practices?

- Yes, geotextiles can be used in green or sustainable building practices. Geotextiles are often utilized as an eco-friendly solution for erosion control, soil stabilization, and filtration in construction projects. They help reduce the need for excessive excavation and grading, minimize erosion and sediment runoff, and promote healthier soil conditions. Additionally, geotextiles can be made from recycled materials or natural fibers, further enhancing their sustainability credentials.

- Q:Geotextile testing standards

- [Geotextile testing standards] The current standard is: GB / T-2008 "geosynthetics filament spunbond acupuncture non-woven geotextile". For details

- Q:Geotextile thinnest how many grams

- 80-100g, I am specializing in the production of geotextile geomembrane, wish smooth

- Q:Can geotextiles be used in railway track stabilization?

- Yes, geotextiles can be used in railway track stabilization. Geotextiles provide reinforcement and separation functions, preventing the mixing of materials and improving the stability of the track. They can help distribute loads, reduce deformation, and enhance the overall performance and lifespan of the railway track.

- Q:What is a polyester filament geotextile? Polyester filament geotextile

- In addition to a good mechanical energy, but also has a good vertical and horizontal drainage and good extension of energy and high resistance to biological, acid and alkali, anti-aging and other chemical stability. At the same time, also has a wide range of pore size, tortuous pore distribution, excellent permeability and filtration can be polyester filament geotextile purposes: water conservancy project dam and slope protection filter, channel isolation, seepage; Airport runway foundation isolation, filter, drainage, soil slope, retaining wall and road reinforcement, drainage; port engineering soft foundation treatment, beach embankment, harbor wharf and breakwater reinforcement, drainage; polyester filament geotextile Has been widely used in the field of infrastructure construction, and gradually applied to a wider range of areas. Polyester filament geotextile technical parameter table (GBT-1998): No. Remarks 1 unit area mass deviation% -6-6-6-5-5-5-5-5-4-4-42 thickness, mm ≥ 553 Width deviation% -054 breaking strength KNM ≥ vertical and horizontal 5 elongation at break% 40-806CBR breaking strength KN ≥ 707 equivalent aperture 090, mm007-02

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Anti-Skid Needle Punched Non Woven Geotextile with High Strength CMAX

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 12000 m²

- Supply Capability:

- 600000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords