Aluminum TIG Welding WireTig Rod for Buidling

- Loading Port:

- Qingdao

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 500 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Aluminum TIG Welding Wire Tig Rod for Buidling

Quick Information:

Class: ER1100

AWS: A5.10

Conforms to Certification: AWS A5.10 ASME SFA A5.10

Weld Process: Tig (GTAW)

Specification:

| AWS Chemical Composition Requirements | |

| Cu = 0.05 – 0.20 | Al = 99.0 min |

| Mn = 0.05 max | Si + Fe = 0.95 max |

| Zn = 0.10 max | Be = 0.0003 max |

| Other = 0.05 each – 0.15 total | |

Available Sizes:

Upon Request, call for more information

Characteristics:

Type ER1100 can be used to weld base materials types 1060, 1070, 1080, and 3003.

Welding Filler Wire

Heat Exchangers

Food Handling Equipment

Rivets

FAQ:

The proper choice of aluminum filler metal mainly depends on the base metal properties to be achieved and welding technique. Post weld cracking, corrosion resistance and behavior under elevated temperature also need to be taken into consideration. Cracking usually can be minimized by choosing a filler metal alloy of higher alloy content then the base metal.

Deposited Chemical Composition % (Typical)

Deposited chemistry is influenced by many factors so no typical analysis can be reported.

Deposited All Weld Metal Properties %

As-Welded

Deposited all weld metal properties are influenced by many factors such as weld process used, so no typical weld metal properties can be reported.

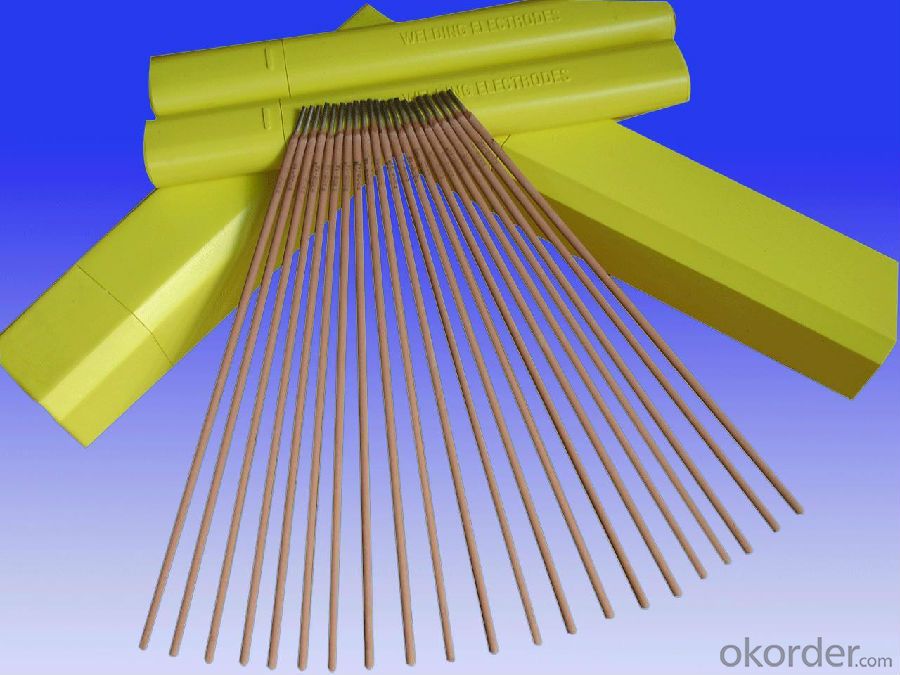

Pictures:

- Q:How to process aluminum wire into 0.1 mm aluminum wire, and the efficiency can not be too low

- Particles in a millimeter, in addition to grinding, there is no other, the more the better

- Q:Pure copper wire for 1 points and 2.5 copper clad wire which is better?

- 2.5 copper wrapped aluminum wire, to withstand the power of 1 than the sheath line of pure copper line, but its line is too hard, if your induction cooker or heater power less than 3 kilowatts, you can use the 1 sheath line.

- Q:The air outlet of an aluminum screw into Skoda crystal sharp front windshield!

- Fell into the outlet no more major events, it will not only have much impression on the car, take it expensive, several hundred, with no matter what is best not to split the table, and a big gap back to the table table,,

- Q:What's the reason for the flash of a LED light?

- In conclusion, the above analysis, the situation will not only this time there will be problems, if you do not want to let people complain to you, or to find manufacturers, or another manufacturer.

- Q:How to make the product more bright when drawing the aluminum wire for the special light agent of aluminum wire drawing?

- The main process control alloy: the process of making aluminum welding wire is a complex process, but INDALCO has obvious unique advantages in this respect.

- Q:Stainless steel soup bucket leaking how to do?

- You can find a better welder to repair it.

- Q:A thin aluminum wire similar to a thin wire

- It shows by wire, aluminum wire and the volume of the same, but the iron density than aluminium, can be used for quality balance of two metal rods, the quality is good, the quality of the aluminum bar is small; can be distinguished according to different material density.

- Q:Why use a sound line aluminum wire, another copper clad aluminum wire?

- That's not aluminumTinned copper wireIf it's aluminum, it breaks off a couple of times

- Q:What kind of welding machine is used for welding aluminum wire?

- Can the use of imported equipment, try the inverter movement, but should not welding, this requirement is almost not up to

- Q:There is aluminium on copper, take off caustic soda, can copper why become red?

- The reaction is aluminum and copper sulfate, copper sulfate and aluminum is produced, the first group of atoms and other trim, trim, trim can be observed by law, so the equation is: 2Al+3CuSO4 Al2 (SO4) 3+3Cu. one so the answer is: remove the oxide film on the surface of aluminum; one is 2Al+3CuSO4 Al2 (SO4) 3+3Cu.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Aluminum TIG Welding WireTig Rod for Buidling

- Loading Port:

- Qingdao

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 500 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords