Aluminum Coil for Casting

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

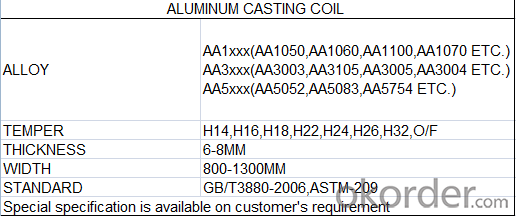

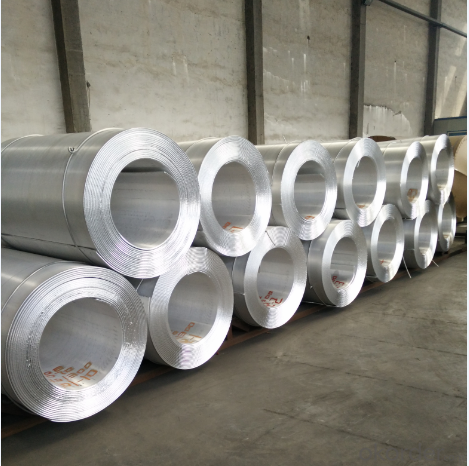

1.Structure of Aluminum Coil for Casting:

Aluminum Master Casting Coil 6-8mm in alloys is used in the factories that produce aluminum coil from 0.2mm to 6mm by thickness. Hot rolled y cold rolled son available. The thickness of Aluminum Casting Coil for thin coil is about 6-8mm. You can choose the alloys as your using and we will do our best to meet your requests.

2.Main Features of the Aluminum Coil for Casting

• Smooth surface

• High manufacturing accuracy

• High strength of extension and yield

• Low tolerance

• Strict quality control

• Well packaged

3. Aluminum Coil for Casting

4. Aluminum Coil for Casting

Cold Rolled

Hot rolled

5.FAQ

We have organized several common questions for our clients,may help you sincerely:

① What is the MOQ of Aluminum Coil for Casting

Usually the MOQ is 150 tons, but we also can make solution according to clients’ situation.

②How about your company?

A world class manufacturer & supplier of aluminum coil and alloy blanks. Aluminum production base is comprised of 18 aluminum annealers, 10 coil and foil mills, 4 continuous production lines, 2 hot rolling production line and 3 prepainted lines.

Export 5000 tons per month to Asia, America and Middle East. Always do the best for our clients.

③Can you guarantee the quality of the products?

We are responsible for the quality of materials in a reasonable period of time to get a long-term cooperation with clients and we are glad to arrange and coordinate any third party inspection for you.

④What is the delivery time after purchase?

15 day with normal specification after receiving client’s deposit or correct LC

- Q:Are aluminum coils compatible with different joining methods?

- Yes, aluminum coils are compatible with different joining methods. Aluminum is a highly versatile metal that can be joined using various techniques such as welding, brazing, soldering, and mechanical fastening. The choice of joining method depends on the specific application and the desired properties of the joint. Welding is commonly used to join aluminum coils as it provides a strong and durable bond. Several welding techniques like MIG (Metal Inert Gas), TIG (Tungsten Inert Gas), and resistance welding can be used depending on the thickness and type of aluminum alloy being joined. Brazing is another effective method for joining aluminum coils. It involves the use of a filler material that has a lower melting point than the base metal, which is heated to create a strong joint. Brazing is commonly used when the aluminum coils need to be joined to other dissimilar metals. Soldering is suitable for joining thin aluminum coils or when a lower temperature method is required. It involves melting a low-temperature alloy (solder) to join the coils together. Soldering is commonly used in electronics and plumbing applications. Mechanical fastening methods such as bolts, screws, rivets, or clips can also be used to join aluminum coils. These methods provide a reliable and removable joint, making them suitable for applications where disassembly may be required. In summary, aluminum coils are compatible with various joining methods, including welding, brazing, soldering, and mechanical fastening. The choice of joining method depends on factors such as the application, the type of aluminum alloy, and the desired properties of the joint.

- Q:What is the weight of aluminum coils?

- The weight of aluminum coils can vary depending on the specific dimensions and thickness of the coils. However, on average, aluminum coils can range in weight from a few hundred pounds to several thousand pounds. It is important to note that the weight of aluminum coils can also be influenced by factors such as the alloy composition and any additional coatings or treatments applied to the coils.

- Q:Can aluminum coils be used in the manufacturing of furniture?

- Yes, aluminum coils can be used in the manufacturing of furniture. Aluminum is a versatile and lightweight material that is often used in the construction of modern furniture. It offers durability, resistance to corrosion, and can be easily molded into various shapes and designs. Additionally, aluminum coils can be coated or finished in different colors and textures to enhance the aesthetic appeal of the furniture.

- Q:What are the transportation and storage requirements for aluminum coils?

- There are several factors that determine the transportation and storage requirements for aluminum coils. Firstly, it is crucial to handle the coils with caution during transportation in order to avoid any harm. Secure packaging is necessary to prevent potential scratches, dents, or deformation. Additionally, safeguarding the coils from moisture is essential as exposure to water or high levels of humidity can result in corrosion. During transportation, it is advisable to employ appropriate vehicles or containers that can sufficiently support the weight and dimensions of the aluminum coils. The coils should be firmly secured to prevent any movement or shifting that may cause damage. Regarding storage, it is of utmost importance to store aluminum coils in an area that is clean, dry, and well-ventilated. Ideally, the storage facility should maintain a stable temperature and humidity level to prevent any negative effects on the coils. If the coils are stored outside, they should be adequately covered and protected from direct sunlight, rain, and other weather conditions. Furthermore, it is crucial to store aluminum coils away from any substances or chemicals that may cause damage. They should be stored in a manner that prevents contact with other materials, as physical contact can lead to scratching or other types of damage. In summary, the transportation and storage requirements for aluminum coils involve careful handling, protection from moisture and corrosive materials, proper packaging and securing during transportation, and storage in a clean and suitable environment. By adhering to these guidelines, the integrity of the aluminum coils can be preserved, ensuring their quality and usability.

- Q:I heard that clay pots and aluminum cans are great caves for my fish to breed in but will the can rust???

- Aluminium will not rust.

- Q:I have found many articles claiming that the aluminum content in soy (baby) formula is very high.What I am wondering is- does regular old soy milk for adult consumption also have very high aluminum content?I am extensively researching all possible ways to relieve my 14 month olds terrible constipation. He is not allergic to milk- he was on a milk-based formula. We VERY slowly switched over to whole cow's milk- which turned out to once again be terribly constipating. It was suggested I give lactose-free milk a try- which has seemed to help a little bit- it was working OK for a few days- but he did have quit the hard (and painful) bowel movement a couple days ago. We are trying other options- juices, he's active, we are trying to get enough fiber into this picky eater's diet. I am just researching the possibility of soy milk if this problem persists.I am not willing to give it to him if the aluminum content is even a small possibility. I am not finding much info about adult soy milk. Anyone??

- I found this on the FAQ for Eden Soy products: Claim 12: Soy foods may contain harmful levels of aluminum. (Fallon, 1996)[21] Answer 12: The author describes aluminum occurring in soy as a result of an industrial processing step. This occurs only when producers use harsh alkaline soaking solutions that leach aluminum from aluminum processing equipment. Not all soy processing uses alkaline soaking solutions and not all soy is produced using aluminum equipment. Harsh alkaline soaking solutions are used mainly in the production of modern soy foods such as soy protein isolates, soy protein concentrates, soy supplements, soy protein shakes, textured soy protein (TSP), etc. Eden does not use alkaline soaking solutions and does not use aluminum equipment. Our test results show no trace of aluminum in Edensoy, testing at a sensitivity of .1ppm. The study it references talks about soy formula, not soy milk. It sounds as if the soy picks up its aluminum content from the manufacturing equipment. Edensoy claims they are aluminum-free (implying that other companies are not)... however, it is of course a biased source! Our oldest has been on soy milk/goat milk combination for a while now (we don't do dairy), however, we are in process of weaning off soy for good as we have other concerns besides aluminum: MEDICAL CONDITIONS POSSIBLY ATTRIBUTABLE TO SOY CONSUMPTION Asthma Chronic Fatigue Depression Diabetes Heart Arrhythmia Heart or Liver Disease Infertility/Reproductive Problems Irritable Bowel Syndrome Learning Disabilities/ADD/ADHD Pancreatic Disorders Premature or Delayed Puberty Rheumatoid Arthritis Thyroid Conditions: Auto-Immune Thyroid Disorders (Graves’ or Hashimoto’s Disease) Goiter Hypothyroidism Hyperthyroidism Thyroid Nodules Thyroid Cancer Other thyroid disorders Uterine Cancer Weight Gain nothing is proven but the possibility is enough for us to give it up).

- Q:What are the energy efficiency benefits of aluminum coils?

- Aluminum coils provide numerous energy efficiency benefits that make them a preferred choice in various industries. Firstly, aluminum is an excellent conductor of heat, allowing for efficient transfer of thermal energy. This property is especially advantageous in the HVAC industry, where aluminum coils are commonly used in air conditioning and refrigeration systems. The high thermal conductivity of aluminum ensures that heat is effectively absorbed or released, resulting in faster cooling or heating processes and lower energy consumption. Additionally, aluminum coils possess exceptional corrosion resistance, which helps maintain their efficiency over time. Unlike other metals that may deteriorate due to exposure to moisture or chemicals, aluminum remains unaffected, ensuring optimal heat transfer efficiency throughout the lifespan of the coil. By preserving the coil's performance, energy losses due to reduced heat transfer are minimized, resulting in energy savings and increased system efficiency. Another significant advantage of aluminum coils is their lightweight nature. Compared to traditional copper coils, aluminum coils are significantly lighter, making them easier to handle during installation and maintenance. The reduced weight also translates into lower energy requirements for transportation, resulting in reduced carbon emissions associated with shipping. Furthermore, aluminum is a recyclable material, making it environmentally friendly and sustainable. The recycling process of aluminum requires significantly less energy compared to primary production, leading to reduced greenhouse gas emissions. By choosing aluminum coils, businesses can contribute to a more sustainable future by reducing their carbon footprint. Overall, the energy efficiency benefits of aluminum coils are vast. Their excellent thermal conductivity, corrosion resistance, lightweight nature, and recyclability make them an ideal choice for various applications, leading to reduced energy consumption, enhanced system performance, and a more sustainable environment.

- Q:What are the compositions of aluminum coil coating?

- Resin, pigment, auxiliary and solvent.

- Q:Will the aluminum braking surface dissipate heat evenly allowing for fast stops from fast descents or will I have to still pulsate braking to reduce heat build up in the tires and tubes?

- Aluminum is tried and true, basalt seems like a gimmick. Aluminum's light, it's sought after over steel, which is cheaper and heavier and stronger. No basalt, no need.

- Q:Can aluminum coils be used in food packaging?

- Yes, aluminum coils can be used in food packaging. Aluminum is a popular choice for food packaging due to its excellent barrier properties, lightweight nature, and ability to maintain the freshness and quality of food products. It is widely used in various forms, including coils, for packaging food items like beverages, snacks, and canned goods.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Aluminum Coil for Casting

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords