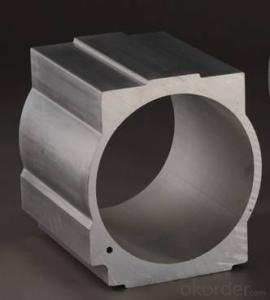

Aluminium Square Pipe-AA 6063

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Aluminum alloy | 6063,6061,6005,6082,7075,1050etc |

Temper | T3-T8 |

shape | square, round, flat, angle ,etc |

surface | Anodizing ,Powder coating, Electrophoresis, etc |

Deep processing ability | Drill hole ,stretch bending, milling, welding, fabrication, etc |

Usage | Windows & door , LED panel, heat sink , curtain wall , solar Panel Frame, rail & fence , ladder ,etc. |

MOQ | 1Ton |

Packing | According to your requirement ,such as shrink wrap, plastic bag, kraft paper ,etc. |

Delivery | 15-20days after sample confirmed & down payment. |

Loading port | Quanzhou, Xiamen |

Shipping term | EXW,FOB,CFR,CIF |

Payment term | T/T,30% advanced deposit, the balance paid off before loading, or consulting |

Moulds | 1,Using our moulds ,no fee |

2,Using customer drawing, opening mould, usually over 4tons then the moulds fee can be refunded | |

3,Mould cost is negotiable base on the order quantity |

- Q:The length of the aluminum tube is about 180mm, the diameter is 19mm, and the wall thickness is about 1mm. It should be bent into the radian of R300. No deformation

- Provide two ways for youThe 1. is what they say is to fill in the sand, the deformation rate should be within 5%, but the efficiency is slow2. is a new type of mandrel bending machine, direct cold bending, deformation rate of 5%, high efficiencyPS: do not use mandrel bending machine, because the mandrel and tube friction, tube wall will be thinned, roundness will be very serious deformation (because your pipe wall thin because), if the tube through objects or liquid, will form dirt

- Q:What are the different polishing techniques for aluminum pipes?

- There are several different polishing techniques that can be used to enhance the appearance of aluminum pipes. Some of the commonly used techniques include: 1. Mechanical Polishing: This technique involves using abrasive materials, such as sandpapers or polishing wheels, to physically remove the surface imperfections and create a smooth and shiny finish on the aluminum pipes. Mechanical polishing can be done manually or with the help of machinery, depending on the size and complexity of the pipes. 2. Chemical Polishing: Chemical polishing is a process where a chemical solution is applied to the surface of the aluminum pipes, which reacts with the metal and removes a thin layer, resulting in a polished finish. This technique is often used for intricate or hard-to-reach areas where mechanical polishing is not effective. 3. Electropolishing: Electropolishing is an electrochemical process that involves immersing the aluminum pipes in an electrolyte solution and applying an electric current. This technique removes surface imperfections and creates a smooth, shiny, and corrosion-resistant finish. Electropolishing is particularly useful for achieving a uniform finish on complex geometries and internal surfaces of pipes. 4. Buffing: Buffing is a technique that involves using a buffing wheel or pad with polishing compounds to remove scratches, stains, and oxidation from the surface of the aluminum pipes. This process helps in achieving a high-gloss finish and restoring the original shine of the pipes. 5. Anodizing: Anodizing is a specialized technique that involves creating a protective oxide layer on the surface of the aluminum pipes by immersing them in an electrolyte solution and applying an electric current. This process not only enhances the appearance of the pipes but also improves their corrosion resistance and durability. It is important to choose the appropriate polishing technique based on the specific requirements of the aluminum pipes, such as their size, shape, and condition. Additionally, it is recommended to follow proper safety precautions and use suitable equipment and materials when performing any polishing technique to ensure optimal results.

- Q:Can aluminum pipes be used for underground electrical conduits?

- Yes, aluminum pipes can be used for underground electrical conduits. Aluminum is lightweight, durable, and resistant to corrosion, making it suitable for burying underground. However, it is important to ensure proper insulation and grounding to prevent any potential issues with electrical conductivity or galvanic corrosion.

- Q:Can aluminum pipes be used for gas distribution?

- Yes, aluminum pipes can be used for gas distribution. They are a popular choice due to their lightweight, corrosion-resistant properties, and ability to handle high-pressure gas systems. However, it is important to use aluminum pipes that meet the specific requirements and standards for gas distribution to ensure safety and compliance.

- Q:What are the top ten enterprises in China's aluminium pipe industry?

- 4 Fenglv aluminum material (A Well-Known Trademark in China China, famous brand, famous brand in Guangdong Province, Guangdong famous brand, Guangdong Feng Aluminum Co. Ltd.)5 Zhong Wang aluminum (China famous brand, China well-known trademark, Liaoning famous brand products, China Zhong Wang Holdings Limited)6 (Chinese Hing Fat aluminum brand, A Well-Known Trademark in China, Chinese aluminum enterprise ten, Xingfa Aluminum Holdings Limited)7 Nanshan aluminum (China famous brand, China well-known trademark, China aluminum enterprise ten, Shandong Nanshan aluminum Limited by Share Ltd)

- Q:Who knows there is a high mountain reed 2plus short tube is what? Urgent!

- A short tube called first aid tent pole, or emergency fault rod, when you appear in the outdoor pole fracture, but also can not be repaired, you can use the emergency fault bar is set in place, so you can still set up the tent,

- Q:How are aluminum pipes manufactured?

- Aluminum pipes are typically manufactured through a process called extrusion. In this process, a cylindrical aluminum billet is heated and forced through a shaped die using a hydraulic press. As the aluminum passes through the die, it takes the shape of the desired pipe, which is then cooled and cut to the required length. This extrusion method allows for the production of aluminum pipes with consistent dimensions, high strength, and good surface finish.

- Q:What causes aluminium tubes to peel and blacken?

- This phenomenon is common when the aluminum pipe is connected with other metals and has electrolyte liquid flow. This is because the electrochemical reaction forms the galvanic cell. Aluminum is the anode, and the surface of the aluminum tube is oxidized to cause blackening and peeling

- Q:What are the different diameters available for aluminum pipes?

- The manufacturer and specific requirements can cause variation in the available diameters for aluminum pipes. Nonetheless, aluminum pipes typically span a range of diameters starting from as small as 0.25 inches (6.35 mm) and extending to larger sizes like 12 inches (304.8 mm) or even larger. The intended use of the aluminum pipes can also influence the specific diameter options available since various industries and applications may necessitate specific sizes. To ensure that your specific needs are met, it is advisable to consult the manufacturer or supplier and ascertain the precise range of diameters for aluminum pipes.

- Q:Are aluminum pipes suitable for power plants?

- Yes, aluminum pipes can be suitable for power plants in certain applications. Aluminum pipes offer several advantages in power plant environments. Firstly, aluminum is lightweight, which makes it easier to handle and install compared to other materials. This can save time and labor costs during construction or maintenance activities. Additionally, aluminum pipes have excellent corrosion resistance properties, allowing them to withstand the harsh conditions often found in power plants, such as high temperatures, humidity, and chemical exposure. Moreover, aluminum has good thermal conductivity, which means it can efficiently transfer heat, making it suitable for applications such as heat exchangers or cooling systems in power plants. However, it is important to note that aluminum pipes may not be suitable for all power plant applications. For instance, in high-pressure systems or where extreme temperatures are involved, other materials like steel or alloys may be more appropriate. Therefore, careful consideration of the specific requirements and conditions of the power plant is necessary to determine if aluminum pipes are suitable for a particular application.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Aluminium Square Pipe-AA 6063

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords