Aluminium Sheets for Different Curtain Walls

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

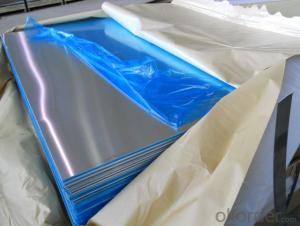

1.Structure of Aluminium Sheets for Different Curtain Walls Aluminum coils are widely used in curtain walls including solar energy curtain wall, unitized curtain wall, stick curtain wall, semi-unitized curtain wall, point-fixing curtain wall, full-glass curtain wall, double-skinned energy-saving curtain wall, steel structure curtain wall, etc. Aluminium Coils for Different Curtain Walls are good at ductility, heat conductivity, anti-corrosion and moisture resistance. They are widely used in roofing, electronics, instruments, lighting decoration, packing, decoration, curtain wall, sandwich panels, boats, etc. 2.Main Features of Aluminium Sheets for Different Curtain Walls •High intensity •Easy to be processed and shaped •Weather resistance •Anti-pollution & environment protection 3. Aluminium Sheets for Different Curtain Walls Images 4.Specification of Aluminium Sheets for Different Curtain Walls Alloy: AA1×××; AA3×××; AA5×××; AA8××× Temper: H14; H16; H18; H22; H24; H26; H32; O; F Thickness: 0.2mm-100mm Width: 30mm-1700mm Standard: GB/T 3880-2006 5. FAQ A.What about inspections to guarantee quality? For each order for Aluminum Sheets, we will arrange strict inspection for raw materials, inspection during production and inspection for finished goods. With requirement of customers, we also can arrange the third party inspection. B.What about delivery? We will put order for Aluminum Sheets in production schedule after order gets confirmed against copy of TT or L/C. Normally it takes about one month for production. Exact shipment schedule is different based on different sizes and quantity. C.What is the MOQ? 5 tons for each size. D. Where have you exported aluminium sheets? We have exported aluminum sheets to many countries. Main markets include South East Asia, Middle East, North America, South America, etc.

- Q:the aluminium pull tabs are in a jucy juice bottle

- 82% okorder /

- Q:How does the surface roughness affect the adhesion of coatings on aluminum sheet?

- The adhesion of coatings on aluminum sheet is greatly influenced by the surface roughness. How rough the sheet's surface is directly impacts the mechanical interlocking between the coating and the substrate, which is vital for strong adhesion. When the aluminum sheet's surface is smooth, the contact area between the coating and the substrate is limited, resulting in weak adhesion. Conversely, a rough surface provides more contact points, enhancing the interlocking between the coating and the aluminum sheet, resulting in improved adhesion strength. Moreover, a rough surface facilitates better wetting of the coating material on the aluminum sheet. This means that the coating material can easily spread across the surface, filling any gaps or crevices and creating a more uniform and continuous coating. This improved wetting contributes to enhanced adhesion. Furthermore, a rough surface can also increase the overall surface area of the aluminum sheet. A larger surface area allows for more available space for the coating material to adhere to, thus increasing the adhesion strength. It is important to note that there is an optimal level of roughness required to achieve the best adhesion. Excessive roughness may result in incomplete coverage of the coating material or the formation of voids, reducing adhesion. Therefore, finding the right balance of roughness is essential to ensure optimal adhesion of coatings on aluminum sheet.

- Q:Are aluminum sheets suitable for use in cryogenic environments?

- Certainly, aluminum sheets prove to be a fitting choice for utilization in cryogenic surroundings. With its exceptional thermal conductivity and low density, aluminum emerges as an optimal substance for cryogenic purposes. It can endure exceedingly cold temperatures while maintaining its structural integrity and avoiding noticeable thermal expansion. Moreover, aluminum exhibits commendable resistance against corrosion and can be conveniently fashioned into diverse configurations and sizes. These attributes render aluminum sheets widely employed in cryogenic systems, including cryostats, superconducting magnets, and liquid nitrogen storage tanks.

- Q:Aluminum siding is essentially maintenence-free, extremelydurable, and is a great insulator, even better than brick. Brickleaks air through the mortar between the bricks, especially in olderhouses that need tuckpointing. My question is, do you feel sidingstill has a declasse connotation, or is it getting more acceptableas the years go on?

- No worse than vinyl. The advantage vinyl has over aluminum is its resistance to denting. Siding is a good finish, but if you've already got a brick exterior, you're wasting the hard hours the masons put in to make it. If the brick has deteriorated or is horribly scarred, like having survived a hurricane or tornado, then sure, siding will spiff it up cosmetically as well as adding insulation value. That said, I'd rather take a house with aluminum siding over wood any day...and vinyl over that. If you get the siding in the color you want, as it's the entire thickness of the vinyl, powerwashing the outside won't take the color off as it could with painted wood or (though less likely) the finish on the aluminum...unless you *like* painting :)

- Q:3003H24 alloy aluminum plate refers to what kind of aluminum plate?

- 3003H241, the first to 3 words led by the expression is: manganese as the main alloying elements of aluminum alloy;2, second, 0 words indicate that the aluminum alloy, its impurity limit content without special control;3, third, fourth digit 03 indicates modification alloy, not too much actual connotation;4. H means products that increase strength by working hardening;5, 24 in 2 said the work hardening and incomplete annealing state (i.e. the degree of work hardening than product requirements after incomplete annealing strength is reduced to the specified index products) 4 means O is intermediate state to the 8 state that value.

- Q:What types of bonds can aluminum form: Covalent, Ionic and/or Metallic?Could you post the source, I've been looking for a while now :/

- I have considerable experience with adhesives of all types and for your project would suggest either 3M's Scotch Weld DP 420 or Loctite's Epoxy Weld bonding compound. Both are two part formulas and are good for bonding aluminum. Hope that helps.

- Q:Are aluminum sheets suitable for medical applications?

- Yes, aluminum sheets are suitable for medical applications. Aluminum is a lightweight and durable material that is resistant to corrosion, making it suitable for medical equipment and devices. It is commonly used in the production of medical instruments, diagnostic imaging systems, and surgical trays. Additionally, aluminum sheets can be sterilized easily, further enhancing their suitability for medical applications.

- Q:Are aluminum sheets suitable for interior design applications?

- Aluminum sheets are an excellent choice for interior design purposes. This material is both versatile and durable, allowing for various creative uses in enhancing the aesthetics of indoor spaces. Its malleability enables easy shaping, cutting, and manipulation, resulting in unique and contemporary designs. Different finishes, such as brushed, polished, or textured, further expand the design options. One major advantage of utilizing aluminum sheets in interior design is their lightweight composition. This feature simplifies handling and installation, reducing labor and transportation expenses. Additionally, aluminum's corrosion resistance makes it perfect for environments with high humidity or moisture, such as bathrooms or kitchens. Aluminum sheets find application in various aspects of interior design, including wall cladding, ceiling panels, room dividers, furniture, and decorative elements. The ability to paint or coat them in different colors allows seamless integration into any design scheme. Furthermore, perforation or engraving can create patterns or intricate designs, adding a distinct visual appeal to the space. Moreover, aluminum is a sustainable material with high recyclability. The recycling process consumes significantly less energy compared to the production of new aluminum, making it an environmentally friendly option for interior design applications. To summarize, the versatility, durability, lightweight nature, corrosion resistance, and manipulability of aluminum sheets make them highly suitable for interior design. They offer numerous design possibilities and can be used in various applications, rendering them a popular choice among designers and architects.

- Q:Can aluminum sheets be embossed or textured?

- Aluminum sheets are indeed capable of being embossed or textured. To achieve this, specialized machinery is employed to press or roll the sheet, thereby creating patterns or designs on its surface. The purpose of embossing or texturing aluminum sheets can be twofold: enhancing the sheet's aesthetic appeal or enhancing its functionality by providing grip or augmenting its strength. These embossed or textured aluminum sheets find widespread usage across different industries, including automotive, interior design, and packaging.

- Q:what will happen when aluminum sheet is put into copper chloride solution?

- the chemical equation of the reaction, 2Al+3CuCl2=2AlCl3+3Cu, the phenomena when aluminum sheet is put into copper chloride solution: there is red solid generating on the surface of aluminum sheet.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Aluminium Sheets for Different Curtain Walls

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords