Aluminium Pipes 6XXX

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 20 Tons m.t.

- Supply Capability:

- 1000 Tons Per Month m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

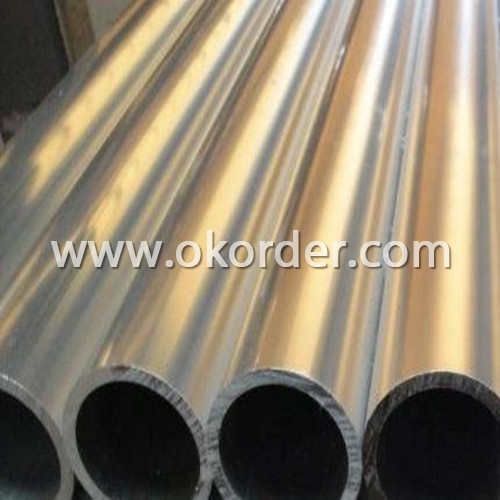

1. Specifications of Aluminum Pipes 6XXX

Alloy Number | AA 6XXX |

Temper | O, F,H112,T4,T5,T6,T3,T8 |

Thickness | 0.5-50mm |

Length | <=13m |

Diameter | Outer: 9-500mm |

Standard | GB/5237.2-2004, ASTM, ISO, EU standard |

Special specification is available on customers' requirements.

2. Usage/Applications of Aluminum Pipes 6XXX

Aluminum pipes are widely used for building construction, housing decorations, industry & agriculture & architecture usage etc.

3. Packaging & Delivery of Aluminum Pipes 6XXX

Packaging: Seaworthy package, bubble plastic bag inside, anti-moisture paper wrapped outside, covered with cartons, on wooden pallets, in containers. Pallet weight: Max. 2.30 tons.

Shipment: the goods will be delivered in 30 days after getting the buyer's payment.

4. Production Flow of Aluminum Pipes 6XXX

Casting--extruding--cutting--coating—further processing--packing

- Q:Are aluminum pipes suitable for greenhouse structures?

- Yes, aluminum pipes are suitable for greenhouse structures. Aluminum is a lightweight and durable material that is resistant to corrosion, making it an excellent choice for greenhouse construction. It is also easy to work with, allowing for flexibility in design and construction. Aluminum pipes provide structural stability and can withstand harsh weather conditions, including strong winds and heavy snow. Additionally, aluminum is a sustainable and recyclable material, aligning with the environmental considerations often associated with greenhouse structures. Overall, the use of aluminum pipes in greenhouse construction offers many benefits and is a suitable choice for creating a stable and long-lasting structure.

- Q:Are aluminum pipes suitable for outdoor use?

- Yes, aluminum pipes are suitable for outdoor use. Aluminum is a highly versatile and durable material that is resistant to rust and corrosion. It has excellent weather resistance properties, making it ideal for outdoor applications. Aluminum pipes are commonly used in various outdoor settings such as construction sites, irrigation systems, outdoor furniture, and outdoor structures. Additionally, aluminum pipes are lightweight and easy to handle, making them a convenient choice for outdoor installations. Overall, aluminum pipes are a reliable and long-lasting option for outdoor use.

- Q:Can aluminum pipes be used for marine applications?

- Marine applications can indeed utilize aluminum pipes. The popularity of aluminum in marine applications stems from its outstanding resistance to corrosion. Unlike steel, aluminum does not rust, making it a perfect choice for saltwater environments. Furthermore, aluminum pipes are both lightweight and durable, enabling easier handling and installation in marine settings. Additionally, they possess favorable thermal conductivity properties, which prove advantageous in certain marine applications. Nonetheless, it is crucial to carefully choose the suitable grade of aluminum pipe specifically designed for marine use to ensure optimal performance and durability.

- Q:Expert: about 100 caliber aluminum tube, manual argon arc welding, single-sided welding, double sided forming technology. And welding process and welding method ~!

- Aluminum tube size 57*4*100; thank you all experts to answer the aluminum tube butt manual tungsten arc welding; single-sided welding double-sided forming technology......

- Q:Can aluminum pipes be used for gas transportation?

- Gas transportation can indeed utilize aluminum pipes. Renowned for its lightweight and robust nature, aluminum boasts exceptional corrosion resistance. Consequently, this material finds widespread application across diverse industries, including gas transportation, thanks to its capacity to endure elevated pressure and temperature circumstances. Furthermore, handling and installing aluminum pipes prove more convenient than their steel counterparts. Nonetheless, it remains crucial to ensure adequate coating or lining of the aluminum pipes to avert any potential interaction between the gas and the metal, as certain gases may react unfavorably with aluminum.

- Q:Can aluminum pipes be used for cooling tower installations?

- Indeed, cooling tower installations can utilize aluminum pipes. Aluminum, a material known for its lightweight and resistance to corrosion, proves to be well-suited for cooling purposes. Its high thermal conductivity and durability render it commonly employed in the construction of heat exchangers and cooling systems. Moreover, aluminum pipes possess superior heat transfer properties, facilitating efficient heat dissipation and effective cooling. Nevertheless, it is crucial to carefully account for the cooling tower system's precise demands, encompassing factors such as temperature, pressure, and water chemistry. This diligence ensures compatibility and the ability of aluminum pipes to endure the operational conditions.

- Q:How do aluminum pipes compare to HDPE pipes in terms of flexibility?

- Aluminum pipes and HDPE pipes differ in terms of flexibility. HDPE pipes are known for their high flexibility due to the nature of the material they are made from. High-density polyethylene (HDPE) is a thermoplastic polymer that possesses a high degree of elasticity and flexibility. This allows HDPE pipes to be easily bent, twisted, and maneuvered around obstacles during installation. On the other hand, aluminum pipes are generally less flexible compared to HDPE pipes. Aluminum is a metal that has a higher rigidity and stiffness compared to HDPE. This means that aluminum pipes are less able to bend or flex without sustaining damage or deformation. They are better suited for applications that require more structural integrity and rigidity, such as in industrial or heavy-duty environments. While aluminum pipes may not be as flexible as HDPE pipes, they offer other advantages such as higher strength, corrosion resistance, and the ability to handle higher pressure and temperature conditions. The choice between aluminum and HDPE pipes should be based on the specific requirements of the project, considering factors such as flexibility, strength, durability, and the environment in which they will be used.

- Q:Can aluminum plastic pipes be used for solar energy pipes?

- If the conditions, it is recommended to use the best copper, plastic contact with hot water is not after all very good, the harmful substances are good materials will decompose the dissolved in water is bad for health.

- Q:Can aluminum pipes be used for structural purposes?

- Yes, aluminum pipes can be used for structural purposes. Aluminum is a lightweight and corrosion-resistant material, making it suitable for a wide range of applications including structural components. Aluminum pipes are commonly used in construction, aerospace, automotive, and marine industries where strength, durability, and weight are critical factors. Additionally, aluminum pipes can be easily formed, welded, and machined to meet specific structural requirements. Overall, aluminum pipes offer a cost-effective and versatile solution for various structural applications.

- Q:The difference between aluminium pipe and galvanized steel pipe

- The aluminum surface has a layer of oxide film, melting point at more than 2000 degrees, and the melting point of aluminum is only about 400 degrees. Galvanized sheet is a sheet of zinc plated on sheet iron or carbon steel.

1. Manufacturer Overview |

|

|---|---|

| Location | Guangdong, China |

| Year Established | 2004 |

| Annual Output Value | Above US$50 Million |

| Main Markets | Mid East;Eastern Europe;North America |

| Company Certifications | ISO 9001:2000;ISO 14001:2004;OHSAS 18001 |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | Shanghai |

| Export Percentage | 30%-50% |

| No.of Employees in Trade Department | 21-50 People |

| Language Spoken: | English;Chinese |

| b)Factory Information | |

| Factory Size: | Above 100,000 square meters |

| No. of Production Lines | Above 10 |

| Contract Manufacturing | OEM Service Offered;Design Service Offered |

| Product Price Range | Average |

Send your message to us

Aluminium Pipes 6XXX

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 20 Tons m.t.

- Supply Capability:

- 1000 Tons Per Month m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords