AA5052 aluminium wire for package and bending

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 2 m.t.

- Supply Capability:

- 20000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1、 Structure of Aluminium Wire Description

Aluminium wire is widely used in ballasts automotive electronics, refrigerator and air

conditioner compressor motors, television sets, electric stove, microwave ovens, various transformers, and other kinds of electronic coil motors, electrical appliances.

2、Main Features of the AA5052 Aluminium Wire

Core number:one

Shape materials:Round

Elongation:>15%

Tensile strength:110MP-130MP

Paint:1730,1736,1745,1754

Packing:Carton

3、 Aluminium Wire Images

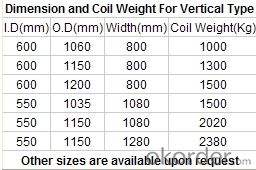

4、Aluminium Wire Specification

5、FAQ of AA5052 Aluminium Wire

a.What is monthly capacity

---CNBM is one stated own company and our monthly capacity is about 2000tons.

b. Now which countries do you export your goods?

----Now we export to South East Asia,Africa, North America,South America ect.

- Q:How did you disconnect the HD line?

- The high definition wire is broken. The copper wire and copper wire are connected. The outer aluminum wire and the aluminum wire are connected. The aluminum wire is twisted directly into one piece. The copper wire and the aluminum wire are separated, and the circuit can not be shorted.

- Q:Petroleum chemical instrument can be used by cable wire lashing it

- Of course, if after the aluminum cold processing (such as bending, torsion, often extrusion) will become hard, in this case you put the aluminum wire is heated to 340 degrees Celsius heat for about 5 minutes -- because aluminum wire is relatively small, so there is no need to heat too long time.

- Q:How to make the product more bright when drawing the aluminum wire for the special light agent of aluminum wire drawing?

- Through this mechanical device, we can strictly control the chemical composition in the alloy.

- Q:The similarities and differences between aluminum wire and copper wire

- The unpolished aluminum is black and polished to a bright silvery whiteCopper conducts electricity better than aluminum does

- Q:The outside of the frying pan is full of strong and thick layers of grease and stains. How can it be removed easily?

- Most housewives wash pot only wash do not wash the bottom surface is wrong, because the bottom covered with inverted vegetables when he returned alone, if not always wash residue at the bottom, bottom thickness gradually thickening in the course of time, the effect of cooking heat, so must be positive and negative, washed and then placed on a stove fire drying to remove water, next time also convenient.

- Q:In the process of spark discharge machining, why hasn't the aluminum wire been fused by the high temperature produced by it?

- Is your work made of aluminium wire? But cutting molybdenum wire with yo line, now on the market are generally the synthesis of tungsten and molybdenum, specific hardness, extend to such characteristics.

- Q:Which industries use carbide wire drawing die?

- Wire, cable, wire rope, wire need cold drawing die.

- Q:Some aluminium wires are soft and some are tough. Why?

- In addition, the aluminum wire has a single core aluminum and multi-core aluminum wire, single core and multi-core aluminum wire compared with copper wire in the soft and hard line, multi-core called flexible cord, single core is called hard wire.

- Q:What is aluminum magnesium alloy aluminum wire?

- Hard aluminium magnesium alloy aluminum lightweight, low density, good heat dissipation, strong resistance, can fully meet the needs of the 3C products are highly integrated, lightweight, miniaturization, anti-collision and electromagnetic shielding and thermal requirements. Its hardness is several times more than traditional plastic chassis, but the weight is only 1/3 of the latter

- Q:Why can't iron solder weld aluminum wire?

- Because the melting point of copper wire and aluminum wire.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

AA5052 aluminium wire for package and bending

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 2 m.t.

- Supply Capability:

- 20000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords