304 Stainless Steel Strips

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 Ton m.t.

- Supply Capability:

- 3000 Tons Per Month m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

AISI 304 Stainless Steel Strips

1. Chemical composition

|

C |

Si |

Mn |

P |

S |

Ni |

Cr |

|

max0.08 |

max1.00 |

max2.00 |

max0.045 |

max0.03 |

8.00-10.50 |

18.00-20.00 |

2. Mechanical properties

|

Yield Strength |

Tensile |

Elongation |

Hardness (HV) |

Hardness (HRB) |

|

≥ 205 |

≥ 520 |

≥ 40 |

≤ 200 |

≤ 90 |

3. Standard: AISI, ASTM, GB, EN, DIN, JIS

4. Surface: 2B, NO.1, BA, NO.4, Hairline, SB, Mirror finish, Anti-skid, Cherkered etc.

5. Size: Thickness: 0.3-3mm (cold rolled), 3-40mm (hot rolled)

Width: 18-600mm

Length: As customers' request.

6. MOQ: 1 Ton

7. Payment terms: T/T or L/C

8. Packing: Seaworthy package with wooden or Iron pallets with the paper and the steel strip, or as customers' request.

9. Delivery time: Usually about 7 days after we confirming the order, or according to your quantity.

If you have any demand, pls feel free to contact me.

- Q:What is the electrical conductivity of stainless steel wire?

- The electrical conductivity of stainless steel wire may differ based on its composition and properties. In comparison to metals like copper or aluminum, stainless steel is generally acknowledged to possess lower electrical conductivity. This is predominantly attributed to its heightened resistance to the passage of electric current. Nevertheless, stainless steel wire retains the ability to conduct electricity to a certain degree, rendering it suitable for diverse applications where electrical conductivity is not of paramount importance.

- Q:Is stainless steel wire suitable for wire rope end fittings?

- Stainless steel wire is indeed a fitting choice for wire rope end fittings. Its exceptional strength, resistance against corrosion, and durability have earned it the status of an ideal material for applications seeking dependable and enduring wire rope end fittings. Stainless steel wire rope end fittings possess the ability to endure adverse conditions, extreme temperatures, and substantial loads, which explains their extensive usage in sectors like marine, construction, and aerospace. Moreover, stainless steel wire rope end fittings exhibit remarkable resistance to rust, chemicals, and UV rays, guaranteeing their long-lasting integrity and performance.

- Q:Can stainless steel wire be used for springs in the furniture industry?

- Indeed, springs in the furniture industry can make use of stainless steel wire. Renowned for its durability, strength, and resistance to corrosion, stainless steel proves to be an ideal material for furniture springs. Its capacity to endure heavy loads and repeated use without diminishing in form or strength guarantees durable support and comfort. Moreover, stainless steel wire can be effortlessly fashioned and crafted into diverse spring designs to cater to the distinct demands of various furniture pieces. The allure it exudes and its ability to withstand different environmental conditions further solidify stainless steel wire springs as a preferred choice in the furniture industry.

- Q:How does stainless steel wire resist corrosion?

- Due to its unique composition and surface properties, stainless steel wire is able to resist corrosion. It is primarily composed of iron, chromium, and nickel, with varying amounts of other elements like molybdenum, titanium, and copper added to enhance specific properties. The presence of chromium is key to stainless steel's corrosion resistance. When exposed to oxygen in the atmosphere, chromium forms a thin layer of protective oxide on the wire's surface. This layer, known as passive film or chromium oxide, acts as a barrier, preventing oxygen and moisture from reaching the underlying metal. Thus, the wire is effectively isolated from the external environment, reducing the likelihood of corrosion. Additionally, the chromium oxide layer has the ability to self-heal. If it becomes damaged or disrupted, it quickly reforms when exposed to oxygen, restoring the wire's corrosion resistance. This self-healing property contributes to the durability and longevity of stainless steel wire. The inclusion of nickel further enhances the wire's corrosion resistance. Nickel helps stabilize the passive film and improves its ability to withstand corrosive agents like acids and chlorides. Furthermore, it helps the wire maintain its strength and ductility even in extreme conditions. The choice of specific stainless steel wire grades also impacts its corrosion resistance. Different grades contain varying amounts of chromium, nickel, and other alloying elements, making them suitable for specific applications. For instance, marine-grade stainless steel wire, such as 316 stainless steel, contains higher levels of molybdenum, which enhances its resistance to chloride-induced pitting and crevice corrosion in marine environments. In conclusion, stainless steel wire resists corrosion by forming a protective chromium oxide layer on its surface, acting as a barrier against oxygen and moisture. The addition of other alloying elements, such as nickel and molybdenum, further enhances its resistance to corrosive agents. These unique composition and surface properties make stainless steel wire an excellent choice for various applications where corrosion resistance is crucial.

- Q:Can stainless steel wire be used for wire drawing dies?

- Certainly, wire drawing dies can utilize stainless steel wire. Stainless steel, a highly adaptable material praised for its robustness, resistance to corrosion, and exceptional strength, proves to be fitting for a multitude of applications, one of which being wire drawing dies. These dies serve the purpose of diminishing the wire's diameter through the act of pulling it through a die hole. Stainless steel wire drawing dies effectively withstand the forces and friction associated with this procedure. Moreover, they are renowned for their enduring performance and capacity to generate wire of superior quality, consistently maintaining precise dimensions.

- Q:What are the different wire mesh options available in stainless steel wire?

- There are several different wire mesh options available in stainless steel wire, each with its own unique features and applications. 1. Plain Weave: This is the most common and basic type of stainless steel wire mesh. It is made by weaving the wires under and over each other in a simple crisscross pattern, resulting in a strong and durable mesh. Plain weave wire mesh is widely used in filtration, sieving, and screening applications. 2. Twill Weave: Twill weave wire mesh is characterized by a diagonal pattern created by passing the weft wire over and under two warp wires. This type of mesh offers a tighter weave and increased strength compared to plain weave. Twill weave wire mesh is commonly used in industrial filtration, separation, and conveyor belt applications. 3. Dutch Weave: Dutch weave wire mesh features a combination of a plain weave and a twill weave. It is made by using thick wires for the warp and thin wires for the weft, resulting in a highly durable and fine mesh. Dutch weave wire mesh is ideal for applications that require precise filtration and separation, such as in the chemical, pharmaceutical, and food industries. 4. Welded Wire Mesh: As the name suggests, welded wire mesh is made by welding the intersections of the wires together. This type of mesh offers excellent strength and rigidity, making it suitable for applications that require a strong barrier or reinforcement, such as in construction, fencing, and animal enclosures. 5. Reverse Dutch Weave: Reverse Dutch weave wire mesh is similar to Dutch weave, but the warp wires are thicker than the weft wires. This type of mesh is frequently used for high-pressure filtration applications, as the thicker warp wires provide greater stability and resistance to pressure. 6. Crimped Wire Mesh: Crimped wire mesh is made by weaving wires with crimped patterns, creating a mesh with uniform openings. This type of mesh is known for its flexibility and resilience, making it suitable for applications that require vibration resistance, such as in mining, construction, and architecture. These are just a few of the many wire mesh options available in stainless steel wire. The choice of mesh depends on the specific requirements of the application, such as filtration precision, strength, flexibility, and durability.

- Q:Can stainless steel wire be used for bicycle spokes?

- Yes, stainless steel wire can be used for bicycle spokes. Stainless steel is a popular material choice for bicycle spokes due to its excellent strength, durability, and resistance to corrosion. Stainless steel spokes are able to withstand high tension and provide a strong support system for the bicycle wheel. Additionally, stainless steel is relatively lightweight and offers a good balance between strength and flexibility, making it an ideal material for bicycle spokes.

- Q:Stainless steel wire why rust?

- In polluted air (e.g., atmosphere containing large amounts of sulfides, oxides of carbon and nitrogen oxides), condensate is formed when sulfuric acid, nitric acid, and acetic acid are subjected to condensation, resulting in chemical corrosion.

- Q:Can stainless steel wire be used for marine applications?

- Yes, stainless steel wire can be used for marine applications. Stainless steel has excellent corrosion resistance properties, making it ideal for use in marine environments where exposure to saltwater and moisture is common. It is commonly used for various marine applications such as rigging, fishing, yacht construction, and marine architectural installations.

- Q:What are the different types of stainless steel wire for different levels of corrosion resistance?

- There are several types of stainless steel wire available, each offering varying levels of corrosion resistance. Some common types include 304 stainless steel wire, which provides good corrosion resistance in general applications; 316 stainless steel wire, known for its excellent resistance to corrosion in marine environments and high chloride environments; and 430 stainless steel wire, which is less corrosion resistant but suitable for less demanding applications.

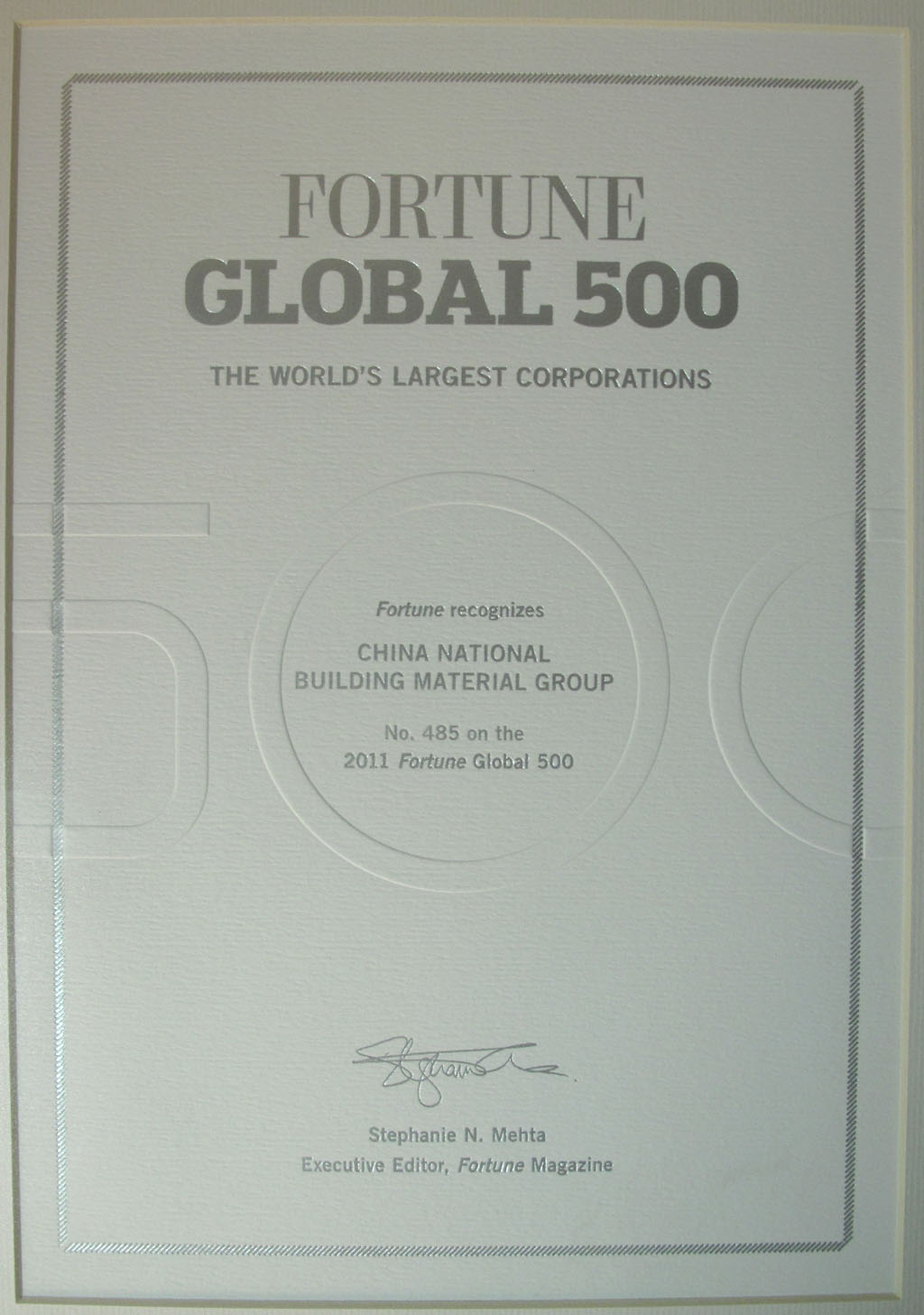

1. Manufacturer Overview |

|

|---|---|

| Location | Shandong,China |

| Year Established | 2005 |

| Annual Output Value | Above US$5.3 Million |

| Main Markets | Europe, China |

| Company Certifications | ISO9001:2000 |

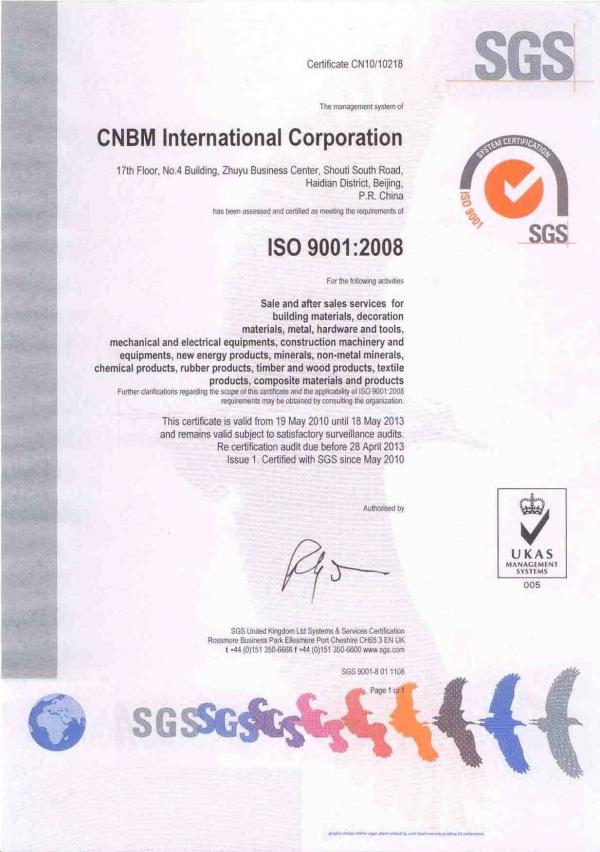

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | Tian Jin |

| Export Percentage | 30% |

| No.of Employees in Trade Department | 40 People |

| Language Spoken: | English;Chinese |

| b)Factory Information | |

| Factory Size: | Above 50,000 square meters |

| No. of Production Lines | Above 8 |

| Contract Manufacturing | OEM Service Offered;Design Service Offered |

| Product Price Range | Average |

Send your message to us

304 Stainless Steel Strips

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 Ton m.t.

- Supply Capability:

- 3000 Tons Per Month m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords