3003 H14 H22 Aluminum Coil Manufacturers

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 9000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description

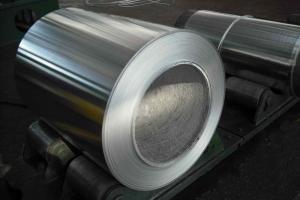

Aluminum coil manufacturers

Temper: O H12/ H14/24 H16/26 H18 H19

Thickness: 0.20-3.0mm

Width: 16-1600mm

Usage: capacitor strip, aluminum plastic composite material, car parts, building decoration materials, stamping products, building mirror materials, nameplate, insulation materials, container package, welding parts, clock surface and disk, kitchen utensils, reflecting apparatus etc.

Application

Machine,auto, can, building, ship and so on.

Packaging & Shipping

Standard export seaworthy package or as cilents' requirement

Company Information

Through the years, we have built many modern production lines, including one 1+2 hot rolling production line, six 2,450, 2,050, 1,650 and 1,450mm cold rolling lines, two 1,650mm foil rolling production lines, two 1,850mm continuous rolling production lines and one roll coating production line. Besides, we also bring in 8 x 20 annealing furnaces, tension leveled machines, tension pre-stretch machines, cutting machines, cleaning equipment, testing machines and packing equipment from at home and abroad to be able to complete various clients' requirements

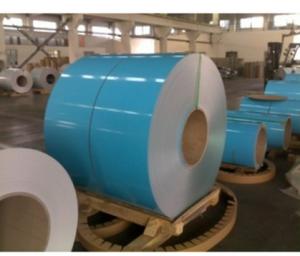

Colored aluminum sheet polyester coating is a UV protection coating; the polyester resin is the use of the main polymer chain of ester bond-containing monomer, adding an alkyd resin, an ultraviolet absorber and can be divided according to the glossiness matt and high-gloss series, especially for interior decoration and advertising boards.

Fluorocarbon colored aluminum sheet is fluorine eneyne fluorocarbon resin basic monomer, a pigment, ester solvents, additives, mixed together. After high temperature barbecue deposition, the molecular structure of the coating becomes tight, with superior weather resistance. According fluorocarbon coating film on the surface structure can be divided into two kinds of conventional fluorocarbon coating fluorocarbon nano. Especially suitable for public places, indoor and outdoor decoration, commercial chains, exhibition and display advertising and other decorative colored aluminum sheet

- Q:Can aluminum coils be used in automotive applications?

- Yes, aluminum coils can be used in automotive applications. Aluminum coils are lightweight, which makes them an excellent choice for automotive manufacturers as it helps to reduce the overall weight of the vehicle. This, in turn, can improve fuel efficiency and performance. Additionally, aluminum coils have excellent heat conductivity, which is crucial in automotive applications where heat dissipation is important. Moreover, aluminum coils have good corrosion resistance, which is particularly beneficial in automotive applications where vehicles are exposed to various weather conditions and road salts. Overall, the use of aluminum coils in automotive applications can provide several advantages such as weight reduction, improved fuel efficiency, better heat dissipation, and enhanced corrosion resistance.

- Q:Which would you guys recommend to a 13 year-old? I used a wooden bat at my last game, and I got a double to the left field wall, I don't think i've done that good with an aluminum bat all year. Should I continue using the wooden one? What do you guys think?

- An aluminum bat may or may not hit a baseball further, depending on who swings the bat. Both bats have advantages. First, let us compare the qualities of the two designs. The only real difference is weight. The aluminum bat is much lighter than the wooden bat. Because the aluminum bat is lighter, the batter has more control. It is easier to make last-minute adjustments to his swing. Once a wooden bat is swinging, adjustments are difficult. Also, less time is needed to get the aluminum bat moving. The batter can wait just a little bit longer before deciding how to swing with an aluminum bat. Because the wooden bat is heavier, it has less recoil: A wooden bat moving at the same speed as an aluminum bat will hit harder. A batter who can get a wooden bat moving fast will hit the ball further, provided he makes contact at all. Also, a wooden bat doesn't vibrate as much. This is better for the batter's hands. Overall, the wooden bat has more potential power, but the aluminum bat is easier to use. A very experienced player that can tell how the ball is pitched just as it leaves the pitcher's hand will do better with a wooden bat. The player that likes a little extra time to decide how to hit, as well as a little opportunity for slight adjustment, will do better with an aluminum bat. In the end, it is a matter of personal preference.

- Q:Does anyone know of any men's deodorant that doesn't contain aluminum? It has to be strong, as I do sweat a lot.

- Neways - works really well. Only thing is, you need a local distributor. But ring the company, I am sure it will help you.

- Q:I have a muffin pan made of aluminum foil and I do not know if i can put it in the oven to cook some muffins. Many sights say it will melt but they say that about putting a sheet of foil at the bottom of the oven for a long time. I just want it to be in their for half an hour to make muffins.

- Aluminum Foil In Oven

- Q:Are there any limitations to the widths of aluminum coils?

- The widths of aluminum coils are subject to certain limitations. Various factors, such as the manufacturing process, equipment capabilities, and industry standards, determine the width of these coils. One limitation arises from the maximum width that the manufacturing equipment can handle. Coil processing machines have specific width capacities, typically ranging from a few inches to several feet. If an aluminum coil exceeds the machine's maximum width capacity, it may not be feasible to process. Another limitation relates to transportation and handling. Aluminum coils that are too wide may not fit into standard shipping containers or may be challenging to maneuver during transportation. Moreover, wide coils may necessitate specialized handling equipment or additional support, leading to increased costs and logistical difficulties. Industry standards and application requirements also influence the limitations on aluminum coil widths. Different industries and applications have specific width specifications for their products. For instance, the construction industry may have particular width requirements for roofing or cladding materials, while the automotive industry may have different demands for body panels. Manufacturers must take these standards and customer needs into account when determining the maximum and minimum widths of aluminum coils. To summarize, while aluminum coils can be produced in various widths, there are limitations due to manufacturing equipment capabilities, transportation constraints, and industry standards. These limitations must be considered to ensure the efficient production, handling, and utilization of aluminum coils in different applications.

- Q:Are aluminum coils suitable for high-strength applications?

- Aluminum coils are generally not suitable for high-strength applications due to their relatively low tensile strength compared to other materials such as steel. Aluminum has a lower strength-to-weight ratio and is more prone to deformation under high loads. However, there are specific alloys of aluminum that have been developed to enhance their strength, such as the 7000 series aluminum alloys, which can offer higher strength levels. These alloys are commonly used in aerospace and automotive industries for their lightweight properties and moderate strength. Nevertheless, for applications requiring the utmost strength, steel or other high-strength materials are usually preferred over aluminum coils.

- Q:How are aluminum coils used in the production of architectural structures?

- Aluminum coils play a crucial role in the production of architectural structures due to their various advantageous properties. These coils are primarily used in the construction industry for their lightweight, strength, and corrosion resistance. One common application of aluminum coils in architectural structures is in roofing systems. The lightweight nature of aluminum allows for easy installation and reduces the overall load on the building. Additionally, aluminum's corrosion resistance ensures that the roofing system remains durable and long-lasting in various weather conditions. Aluminum coils are also utilized in the fabrication of exterior cladding systems. The coils can be formed into different shapes and sizes, making them suitable for creating unique and visually appealing architectural designs. Furthermore, aluminum's ability to resist corrosion and withstand harsh environmental factors makes it an ideal choice for cladding systems, ensuring the longevity and aesthetics of the structure. In addition to roofing and cladding, aluminum coils are commonly used in the production of windows and doors for architectural structures. The lightweight nature of aluminum makes it easy to handle and install, while its high strength provides structural integrity to these components. Moreover, aluminum's corrosion resistance allows for long-lasting windows and doors that require minimal maintenance. Overall, aluminum coils are an integral part of the production process for architectural structures. Their lightweight, strength, and corrosion resistance make them a preferred choice for roofing, cladding, windows, and doors. By utilizing aluminum coils, architects and builders can create durable, aesthetically pleasing, and sustainable structures that withstand the test of time.

- Q:Which companies will use aluminum sheet and coil?

- Aluminum sheet coating plant

- Q:Can aluminum coils be used in the production of aluminum sunshades?

- Yes, aluminum coils can be used in the production of aluminum sunshades. Aluminum coils are typically used as a starting material in the manufacturing process of aluminum sunshades. These coils are made from high-quality aluminum, which is known for its lightweight and durable properties. The coils are then fabricated and shaped into the desired form for the sunshade, whether it be slats, louvers, or a solid panel. Aluminum is a popular choice for sunshades due to its corrosion resistance and ability to withstand various weather conditions. Additionally, aluminum is easily recyclable, making it an environmentally friendly material for sunshade production. Overall, aluminum coils are an essential component in the production of aluminum sunshades, providing strength, durability, and aesthetic appeal to these shading structures.

- Q:What is the typical lead time for manufacturing aluminum coils?

- The typical lead time for manufacturing aluminum coils can vary depending on several factors such as the specific requirements of the order, the complexity of the manufacturing process, and the current demand and capacity of the manufacturer. In general, lead times for aluminum coil production can range from a few weeks to several months. For standard aluminum coil orders, where the specifications and quantities are within the manufacturer's regular production capabilities, the lead time is usually shorter and can be around 4-8 weeks. This includes the time required for raw material sourcing, processing, and quality control checks. However, for custom or specialized aluminum coil orders that require specific dimensions, finishes, or additional processing steps such as coating or embossing, the lead time can be longer. These types of orders may require additional time for design and engineering, tooling setup, and testing, which can extend the lead time to approximately 8-12 weeks or more. It is important to note that lead times can also be influenced by external factors such as the availability of raw materials, transportation delays, or unforeseen production issues. Therefore, it is always advisable to communicate with the manufacturer to get an accurate estimate of the lead time for specific aluminum coil orders.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

3003 H14 H22 Aluminum Coil Manufacturers

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 9000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords