201, 202,301, 304, 316,304L,316L,309,410,430 Stainless Steel Coil

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2 m.t.

- Supply Capability:

- 15000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Item specifice

201, 202,301, 304, 316,304L,316L,309,410,430 Stainless Steel Coil

Thickness:0.1-120mm

Width:1000-2000mm

Length: As required

Typical physical properties for stainless steel coil

Grade | Chemical composition | ||||||

C | Si | Mn | P | S | Ni | Cr | |

% | % | % | % | % | % | % | |

309S | ≤0.08 | ≤1.00 | ≤2.00 | ≤0.04 | ≤0.030 | 12.00-15.00 | 22.00-24.00 |

Item | 201, 202,301, 304,316,304L,316L,309,410,430 Stainless Steel Coil |

Technical | Hot rolled and cold rolled |

Standard | ASTM A240,GB/T3280-2007,JIS4304-2005,ASTM A167,EN10088-2-2005,GB/T3280-2007,EN10095-99,JIS4312,etc |

Material | 201, 202,301, 304,316,304L,316L,309,410,430 |

Surface | NO.1,2B, mirror finish,4K,8K,Hairline finish |

Thickness | 0.1-120mm |

Width | 1000-2000mm |

Price term | FOB,CFR,CIF,CNF |

Application | Stainless steel coil applies to construction field, ships building industry, petroleum, chemical industries, war and electricity industries, food processing and medical industry, boiler heat exchanger, machinery and hardware fields. Stainless steel coil can be made according to the customer’s requirements. |

Contact | If you have any question, please feel free to contact me. |

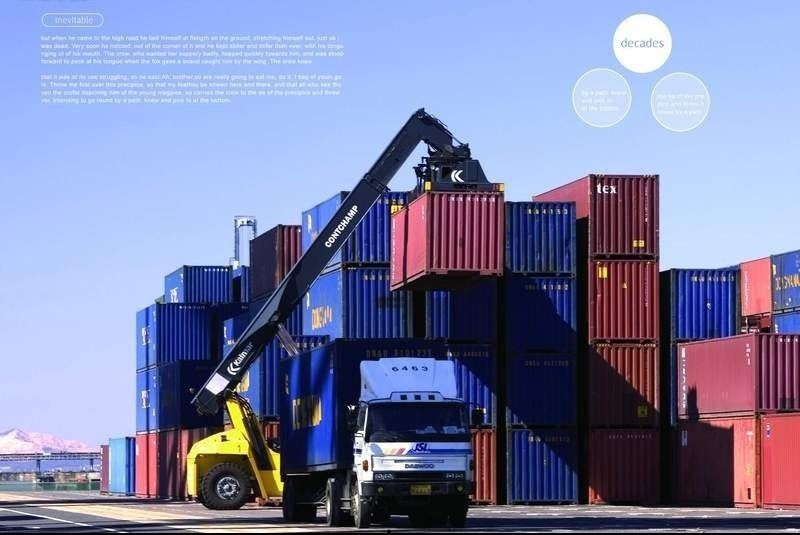

Packaging & shipping

Standard export seaworthy packing (with waterproof paper, metal belt pack sheet,

then put them in wooden pallet, then put in container) or customized.

Products are packed and labeled according to the regulations and customer's request.

Grate car is taken to avoid any damage which might otherwise be caused during storage

or transportation. In addition, clear labels are tagged on the otside of the packages

for easy identification of the product I.D. and quality information.

20 ft - GP: 5.8m (Length) * 2.13m (Width) * 2.18m (Hight) ------ About 23MTS

40 ft - GP: 11.8m (Length) * 2.13m (Width) * 2.18m (Hight) ------ About 27MTS

40 ft - HG: 11.8m (Length) * 2.13m (Width) * 2.72m (Hight) ------ About 27MTS

Production Machines

Application

Applications of Stainless Steel Coil:

1.Automotive: Automotive trim and molding/Difficult-to-form exhaust-system components, tubular manifolds, mufflers/Exhaust manifold and other exhaust-system components, catalytic converter shells, clamps

2. Construction: Gutters and downspouts, roofing, siding

3. Kitchenware: Cooking utensils, dishwashers, ovens, range hoods, refrigerators, skewers 4.Chemical processing: Oil refinery equipment, oil burner and heater parts

5. Appliances: Hot water tanks, residential furnaces

6. Power generation: Heat Exchanger tubing

7. Farming: Dry fertilizer spreaders/Farm animal pens

FAQ

why choose us?

1. All products are made of high-quality imported raw materials.

2. Our product passed SGS,BV,ISO certifications etc.

3. We are nominated as the AAA enterprise .

4. High corrosion resistant

5. Quickest and most efficient Response to Your Enquiry.

6..Stocked products and prompt delivery

7.Multiple payment terms

8.We offer competitive price(high quality)with best service

9.We have high technical production line

10.We have win high reputation based on best quality products

- Q:Are 111 stainless steel strips resistant to pitting and crevice corrosion?

- Yes, 111 stainless steel strips are resistant to pitting and crevice corrosion.

- Q:How do you prevent rust on stainless steel strips?

- To prevent rust on stainless steel strips, it is essential to keep them clean and dry. Regular cleaning with mild soap and water helps remove any dirt or contaminants that may cause corrosion. Additionally, avoiding exposure to harsh chemicals, acids, or chloride-containing compounds can help protect the stainless steel from rusting. Applying a protective coating or using a rust inhibitor can also be effective in preventing rust formation on stainless steel strips.

- Q:Are stainless steel strips resistant to stress corrosion cracking?

- Generally, stainless steel strips are resistant to stress corrosion cracking. The presence of chromium in stainless steel creates a protective oxide layer on the metal's surface, which acts as a barrier against corrosive elements like chloride ions that often cause stress corrosion cracking. However, it is important to note that the resistance to stress corrosion cracking can vary depending on the specific grade of stainless steel and the environment it is exposed to. Austenitic stainless steels, such as 304 and 316, have excellent resistance to stress corrosion cracking in most environments. Nevertheless, in aggressive environments with high concentrations of chloride ions or high-stress conditions, even stainless steel can be susceptible to stress corrosion cracking. In such cases, using higher alloyed grades of stainless steel or applying additional corrosion prevention methods may be necessary for optimal resistance to stress corrosion cracking. Overall, stainless steel strips are generally highly resistant to stress corrosion cracking, making them a reliable choice for various applications in corrosive environments.

- Q:How do stainless steel strips resist crevice corrosion?

- The unique composition and protective oxide layer of stainless steel strips make them highly resistant to crevice corrosion. This type of corrosion occurs in confined spaces or crevices with limited oxygen levels, such as gaps or joints between two surfaces. It is particularly detrimental as it can cause localized damage and material failure. Stainless steel strips primarily consist of iron, but also contain chromium and other alloying elements. Chromium is the key component that provides stainless steel with its corrosion-resistant properties. When exposed to oxygen, chromium forms a passive oxide layer on the steel's surface. This oxide layer acts as a protective barrier, preventing the underlying metal from being exposed to corrosive substances. The chromium-rich oxide layer on stainless steel strips is extremely stable and has the ability to self-heal. It can repair itself when damaged, even in harsh environments. This characteristic is essential in resisting crevice corrosion, as the oxide layer can effectively seal off crevices and prevent corrosive agents from penetrating. Furthermore, the presence of other alloying elements in stainless steel, such as molybdenum and nickel, further enhances its resistance to crevice corrosion. These elements improve the overall corrosion resistance of stainless steel, making it more suitable for applications where crevices or gaps are present. To summarize, stainless steel strips resist crevice corrosion by forming a protective oxide layer that seals off crevices and prevents corrosive substances from penetrating. The composition of stainless steel, including the addition of chromium and other alloying elements, plays a crucial role in its corrosion resistance properties.

- Q:Can stainless steel strips be used for electrical enclosures?

- Yes, stainless steel strips can be used for electrical enclosures. Stainless steel is a highly durable and corrosion-resistant material, making it suitable for protecting electrical components from external elements and providing long-term reliability.

- Q:Can stainless steel strips be bent or folded without cracking?

- Stainless steel strips possess the ability to be bent or folded without experiencing any cracking. The exceptional ductility and formability of stainless steel allow for effortless manipulation into diverse shapes without sustaining any fractures. However, it is crucial to consider the recommended bend radius, which pertains to the tightness of the bend, in order to prevent any potential damage or cracking to the material. Furthermore, the bendability of the stainless steel strip can also be influenced by its type and thickness, with thinner strips generally exhibiting greater flexibility. In summary, if appropriate techniques and parameters are adhered to, stainless steel strips can be subjected to bending or folding processes without encountering any cracking.

- Q:Can stainless steel strips be used in chemical storage tanks?

- Yes, stainless steel strips can be effectively used in chemical storage tanks. Stainless steel is highly resistant to corrosion and can withstand the harsh chemical environment, making it a suitable choice for storing various chemicals.

- Q:What are the recommended safety precautions for handling 111 stainless steel strips?

- When handling 111 stainless steel strips, it is important to follow certain safety precautions. These may include wearing protective gloves and safety glasses to prevent cuts and eye injuries. Ensuring proper ventilation in the work area is also crucial to avoid inhalation of any fumes or dust particles released during handling. Additionally, using appropriate lifting equipment or techniques can help prevent strain or injuries to the back and muscles. Regularly inspecting the strips for any sharp edges or defects and storing them in a secure manner can further reduce the risk of accidents.

- Q:What is the weight of stainless steel strips?

- The dimensions and thickness of stainless steel strips can cause variations in their weight. In general, stainless steel has a density of approximately 7.93 grams per cubic centimeter. In order to determine the weight of a stainless steel strip, it is necessary to have knowledge of its length, width, and thickness. By multiplying the strip's area by its thickness and density, one can ascertain its weight.

- Q:Are 111 stainless steel strips suitable for heat recovery systems?

- Yes, 111 stainless steel strips are suitable for heat recovery systems. Stainless steel is known for its high heat resistance and durability, making it an excellent choice for heat recovery applications.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

201, 202,301, 304, 316,304L,316L,309,410,430 Stainless Steel Coil

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2 m.t.

- Supply Capability:

- 15000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords