140 Type Steel Frame Formwork for Wall and Column and Beam Construction

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 200 m²

- Supply Capability:

- 50000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1. Structure of 140 Steel frame formwork

With adjustable flexiable sizes of frame, the 140 series steel formwork is a heavy-bearing steel frame formwork works with steel frame, plywood and lock. It is widely used in various projects and reduce cost by using standardized sizes of forms as well. The concrete surface is quite clean.

2. Main Features of 140 Steel frame formwork-Column formwork

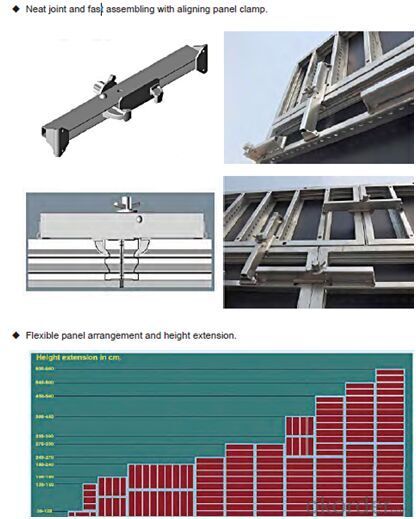

◆ Few parts for fast forming.

◆ Max. Concrete pressure: 80KN/m2.

◆ Hot-dip galvanized steel frame.

◆ The thickness of plywood is 18mm & the panel is 350px..

◆ Compatibility with Hunnebeck Manto system due to similar edge profile.

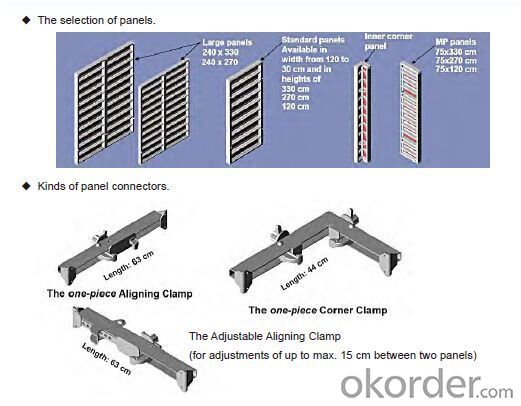

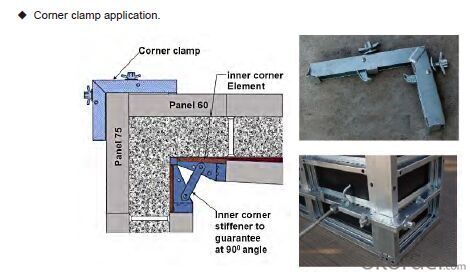

3. 140 Steel frame formwork-column formwork Images

4. 140 Steel Frame Formwork Specifications

5. FAQ of 140 Steel Frame Formwork

1) What can we do for you?

.We can ensure the quality of the140 Steel frame formwork and avoid extra expenses for customers.

.We can provide you the professional technical team.

.We can provide professional building proposal for your projects.

2) What promises can be done by us?

. please feel free to write us for any QUOTE.

. If need any technical and building assistance, we could provide on-site professional staff for instruction.

. Please DO check goods when courier knocks your door and contact us asap if any issueS.

3) What about of our after-sale services?

. Response will be carried out in 24hours after receiving any complain or request.

. Any formwork cost can be refund after order is confirmed.

. If the products are not based on the requirements, there will be the relevant compensations made for you.

4) What about the package and shipping time?

.Packing: wood package and adhesive tape

.Shipping: by sea

Shipping time: Normally small orders, it just1week business days to arrive your hand; When comes to the customs declaration, it may need 2weeks.

- Q:How does steel frame formwork help in achieving accurate concrete alignment?

- Steel frame formwork helps in achieving accurate concrete alignment by providing a rigid structure that supports the weight of the concrete and prevents any movement or deformation during the pouring and curing process. The steel frame ensures that the formwork remains in place without any shifting, resulting in precise and straight concrete walls or slabs. Additionally, the steel frame formwork allows for easy adjustments and alignments, ensuring that the concrete is poured and shaped exactly as intended, resulting in accurate alignment of the final structure.

- Q:How does steel frame formwork handle vertical and horizontal loads?

- Steel frame formwork is designed to handle both vertical and horizontal loads efficiently. The rigid structure of the steel frame provides excellent resistance against vertical loads such as the weight of concrete, construction equipment, and workers. Additionally, the horizontal loads generated by wind or lateral forces are effectively counteracted by the robustness and stability of the steel frame formwork system. This ensures that the formwork remains stable and reliable, providing a safe working environment for construction activities.

- Q:Can steel frame formwork be used in curved or irregular structures?

- Indeed, curved or irregular structures can utilize steel frame formwork. With its exceptional adaptability in terms of shape and design, steel frame formwork proves to be fitting for such structures. The steel frames can effortlessly be modified and curved to achieve the desired shape, enabling the creation of distinctive and intricate structures. Furthermore, steel frame formwork guarantees utmost strength and stability, thus safeguarding the structural integrity of curved or irregular structures. All in all, steel frame formwork presents itself as a flexible and trustworthy option for the construction of curved or irregular structures.

- Q:Can steel frame formwork be used for both residential and industrial construction projects?

- Yes, steel frame formwork can be used for both residential and industrial construction projects. Its versatility, durability, and ability to withstand heavy loads make it suitable for various types of construction projects.

- Q:How does steel frame formwork affect the overall project timeline?

- Steel frame formwork can significantly impact the overall project timeline in a positive way. Its modular nature allows for faster assembly and disassembly, resulting in quicker construction cycles. Moreover, steel frame formwork provides high durability and strength, minimizing the need for repairs or replacements, thus reducing potential delays. Additionally, its versatility enables efficient customization, adapting to various project requirements. Overall, steel frame formwork can expedite the construction process, enhancing the project timeline by saving time and ensuring smooth progress.

- Q:Problems and solutions of bamboo plywood formwork

- (3) JG/T3026-1995 surface quality problems of bamboo plywood according to the classification of plain surface bamboo plywood, composite wood bamboo plywood, bamboo plywood and film covered bamboo 4. The removal of bamboo plywood in concrete after leaving the surface of the bamboo texture, surface treatment is mainly caused by the surface is easy to cut corners, damage, and rubber with plastic mulch

- Q:How does steel frame formwork contribute to the overall cost-effectiveness of a project?

- There are several ways in which steel frame formwork contributes to the cost-effectiveness of a project. To begin with, steel is a durable and long-lasting material, allowing for the multiple reuse of the formwork. This eliminates the constant need to purchase new formwork materials, resulting in significant cost savings throughout the project. Furthermore, assembling and disassembling steel frame formwork is a simple and efficient process, saving time and labor costs. This streamlined approach enables faster construction timelines, ensuring projects are completed within the specified time frame and reducing overall project costs. In addition, steel frame formwork provides exceptional accuracy and precision when pouring concrete, resulting in a high-quality finish. This eliminates the need for costly and time-consuming rework or repairs. Moreover, steel frame formwork is highly versatile and can be utilized in various types of construction projects, such as buildings, bridges, and tunnels. Its adaptability reduces the need for different types of formwork systems, ultimately reducing costs associated with purchasing and storing multiple formwork materials. Lastly, steel frame formwork is resistant to adverse weather conditions, guaranteeing its durability and minimizing the risk of damage or deterioration. This extended lifespan reduces maintenance and replacement costs, making steel frame formwork a cost-effective choice for construction projects. Overall, employing steel frame formwork presents numerous cost-saving advantages, including material reusability, time efficiency, high-quality finishes, versatility, and durability.

- Q:Can steel frame formwork be used for the construction of residential buildings?

- Yes, steel frame formwork can be used for the construction of residential buildings. Steel frame formwork is a versatile and durable system that offers several advantages over traditional formwork methods. Firstly, steel frame formwork provides a higher level of precision and accuracy in construction. The steel frames are designed to be rigid and stable, ensuring that the concrete is poured and set in the desired shape and dimensions. This results in a more consistent and uniform finish, which is especially important in the construction of residential buildings where aesthetics play a crucial role. Additionally, steel frame formwork is highly reusable, making it a cost-effective solution for residential construction projects. The frames can be easily dismantled and reassembled for use in subsequent projects, reducing the need for new formwork materials and minimizing waste. This not only saves money but also promotes sustainability in construction practices. Furthermore, steel frame formwork offers faster construction times compared to traditional formwork methods. The modular design of the frames allows for quick and efficient assembly, resulting in reduced construction schedules. This is particularly advantageous in residential construction where time is of the essence, as it allows homeowners to move into their new homes sooner. Lastly, steel frame formwork provides enhanced safety during construction. The rigid steel frames offer stability and support, reducing the risk of accidents and ensuring the safety of workers on the construction site. In conclusion, steel frame formwork is a suitable and effective method for the construction of residential buildings. Its precision, reusability, speed, and safety benefits make it an ideal choice for developers and builders looking to deliver high-quality residential projects efficiently.

- Q:Can steel frame formwork be used for architectural concrete finishes?

- Yes, steel frame formwork can be used for architectural concrete finishes. Steel frame formwork offers a high level of precision and accuracy in shaping and molding the concrete, making it suitable for achieving architectural concrete finishes. The steel frames provide stability and support to the formwork, ensuring that the desired shape and design of the concrete is maintained throughout the pouring and curing process. Additionally, steel frame formwork can be easily adjusted and modified to accommodate different architectural designs and complex shapes. The smooth and seamless surface of the steel formwork also contributes to achieving a high-quality architectural concrete finish.

- Q:Cross stitch mounting, with steel frame or wooden frame

- With the expansion tube, self tapping screws into the first, tapping screws do not fully drill into the back of the exposed 0.5cm,

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

140 Type Steel Frame Formwork for Wall and Column and Beam Construction

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 200 m²

- Supply Capability:

- 50000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords