Refactory Cement

Refactory Cement Related Searches

Fiber Sheet For Roof Waterproofing Additive For Cement Render Stainless Steel Hot Tubs Stainless Steel Draining Board Aluminum Foil Hot Rail Hot Aluminum Foil Trick Pig Hot Water Bottle Cover Tartan Hot Water Bottle Cover Electric Hot Water Bottle Argos Funny Hot Water Bottle CoversHot Searches

Price For Stainless Steel Scrap Scrap Price For Stainless Steel Price For Stainless Steel Price Of Shipping Containers For Sale Stock Price For Aluminum Air Pump For Aquarium Price Used Foam Board Insulation For Sale Bags Of Cement For Sale Types Of Temporary Side Panels For Cement Deck Magnesium Oxide Board For Sale Hdf Board For Sale sintra board for sale Solar With Inverter Price Pedestal Fan With Water Spray Price Price Of Scrap Stainless Steel Price Of Stainless Steel Scrap Price Of Stainless Steel High Mast Light Price List Solar High Mast Light Specification Steel Mesh Panels For SaleRefactory Cement Supplier & Manufacturer from China

Okorder.com is a professional Refactory Cement supplier & manufacturer, offers integrated one-stop services including real-time quoting and online cargo tracking. We are funded by CNBM Group, a Fortune 500 enterprise and the largest Refactory Cement firm in China.Hot Products

FAQ

- What refractories can withstand high temperature above 2100 degrees?

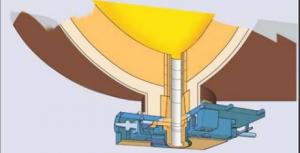

- It depends on refractoriness of refractory materials. The three refractory bricks above is 300 degrees higher than quartz sand in refractoriness. Magnesia brick: Cast corundum brick with greater than 2000 degrees refractoriness should be enough for you to use. But products like quartz sand merely keeps 1600 to 1700 in refractoriness generally. As you described that refractoriness is greater than 1990 degrees, it is feasible to use hearth made by mixing of quartz sand and refractory cement, which can work for some time at 200 degrees. It is also ok to use dolomite brick whose refractoriness is greater than 2000 degrees.

- Detailed description of magnesia dolomite refractory material?

- The use of low chromium or chrome free refractories is more and more widely used, developed countries in the development of chrome free refractories to replace the chromium containing material, through research and production practice show that dolomite refractories is the refining of AOD furnace, large cement kiln ideal material.

- What is the appropiate thickness if fire resistant time for ultra thin steel structure coating is 2.5 hours?

- A level fire resistant steel structure building steel column cannot be constructed with super thin steel structure fire retardant coating, because the ultra thin steel structure fire retardant limit is less than 3 hours. Thin fire retardant coating for steel structure is water borne fireproof coatings painted on the surface of steel structure. It will form carbonized fireproof heat insulation protective layer to insulate oxygen and delay the speed of heating steel structure when it catches on fire, avioding the rapid temperature rise of steel structure and increasing its fire resistant limit. Fire resistance performance: The 2mm coating ≥ 60min, 3mm 100min.

- Can the teflon material resist fire?

- Teflon does not burn and with the ability of flame retardant.

- How to divide the fire resistant level of construction thermal insulation materials?

- Combining three versions of GB8624 (1997,2006,2011), external wall thermal insulation fire?rating can be basically divided into: A1, A2, B1, B2, B3 and other levels. There are many technical indexes for specific division. And it is mainly determined in accordance with the national standard GB8624 Building materials combustion levels.

- What is required to do refractory material?

- I have no idea

- Who knows how many poured refactory material are there?

- Casting refractory material, refractory material used often are AZS brick, corundum brick, direct bonding magnesia chrome brick, silicon carbide, silicon nitride bonded silicon carbide brick, nitrides, silicides, sulfide, boride, carbide and other non oxide refractory materials; calcium oxide, chromium oxide, aluminum oxide, magnesium oxide, beryllium oxide and other refractory materials.

- which kind of material should be used in fireproofing cabinet?

- Natural stone,marble. advantage: Colorful, soft texure, natural and diverse texture, easy to cut or engraving molding. Disadvantages: Because it is a natural formation, tiny loose crackle is easily folded, because the stone is porous material structure, if sewage and waste water permeate in the structure in the process of production, transportation or construction, it's difficult to clean and easy to crack. In daily cleaning, it is inevitable that there will be some residue left, and dirt is filled into crack under the wiping of rag and becomes a breeding ground for bacteria. 2, granite. advantages: Granite has big density and high hardness, with wear-resistant surface, it's one of the most common materials for family decoration. Compared with natural marble, it can be used in the materials of kitchen countertops, and granite has good anti-bacterial regeneration ability. Disadvantages: As the cabinet table material, natural stone is usually not very long, so in order to produce a long overall table (especially U-shaped, L-type table), it will certainly exist joints, which are also easy to hide dirt. 3, artificial stone. advantages: Artificial stone has richful lines and colors, and it can be comparable to stone, it's non-toxic, non-radioactive, easy to clean, and can be truly seamless splicing. it belongs to economic environmentally friendly material. Disadvantages: Artificial stone belongs to the processing industry, and has low technology requirements, The inferior products of many small companys are fulled in the market and damage customers' interests. There exist faded color,poor aging resistance,oil stain and other issues in affordable products.